Prepainted Galvanized Rolled Steel Coil/Sheet from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

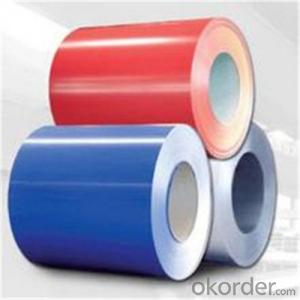

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

Thickness:0.15mm-1.2mm

Width:600mm-1250mm

Coil ID:508mm/610mm

Base Metal: GI/GL.

Zinc Coating:30-275 G/M2

Paint Coating: Top 30; Back 5-7. Or up to Buyer’s Option.

With Protection Film or Without Protection Film.

Spangle: Regular Spangle, Small Spangle, Zero Spangle.

Coil Weight:3-5MT or Customized Weight.

Delivery:15-25 days

MOQ:25MT

Color: RAL Color Series or Customized Colors.

Temper: Commercial Quality G 350; Structural Quality: G550; Full Hard.

Charactics of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Images of Prepainted Galvanized Steel:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products

- Q: I looking at replacing a few of the panels on my car with either Carbon Fiber or High Tensile Steel to shave off some weight and increase mpg and take some time off my quarter mile. Which is better: Carbon Fiber or High Tensile Steel?

- There's different types of strength. Linear strength, the carbon fiber is stronger and more resilient. It's also much lighter, as much as 1/10th the weight of an aluminum body panel (which is lighter than steel). So, by using steel body panels, you would actually likely be ADDING weight to your car. Carbon fiber parts, of course, usually cost 2-3 times as much as their aluminum counterparts. Needless to say, consider the alternative. You can get an aluminum fender, have it be lighter than the steel part, not quite as light as the carbon fiber, but for the price of 1 carbon fiber fender, you could have a both front fenders and the hood in aluminum. Also, for the 1/4 mile, every 100lbs will drop 1/10th of 1 second off your time, which can be lost by screwing up your launch, or in other words, yo won't notice it. As for fuel economy, you won't notice a difference of more than .1-.2mpg. I know this first hand.

- Q: Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or indented patterns on a surface, and it can be done on various materials including steel coils. This technique is often used to enhance the aesthetic appeal or provide functional properties to the steel coils.

- Q: How are steel coils used in the production of electrical transmission poles?

- Steel coils are used in the production of electrical transmission poles as the primary material for constructing the pole itself. The steel coils are typically cut and shaped into the desired dimensions, then welded together to form the pole structure. This provides strength, durability, and stability to withstand the load and environmental conditions associated with electrical transmission lines.

- Q: I am planning to buy a Walther P22. I have liked the Pistol's performance-superb.The only confusion that I have is about the Polymer Frame.Just for this I may shift to someother manufacturer.Are Polymer Frames better than Steel in durability and lifespan.Walther says YES.Any comments on this...Practical users...Thanks in advance

- All polymer frames are cast around steel 'skeleton' inserts, which bear the stress and wear between receiver slide, as well as other wear points. The great advantage to polymer frames is the lower weight over the polymer composite compared to an all-steel or other metal alloy receiver frame. As all wear contact points are 'steel-to-steel', the service life expectancy of a polymer-frame weapon will be the same as an all-steel frame design. NO polymer-frame design I know of has ANY stress or load contact points between metal and polymer-only surfaces. My polymer-frame H-K USP and my Glocks are constructed this way.

- Q: What are common uses for steel coils?

- Common uses for steel coils include manufacturing automobiles, construction materials, appliances, pipes, and various industrial applications such as manufacturing machinery and equipment.

- Q: How are steel coils protected against corrosion?

- Steel coils are protected against corrosion through a process known as galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing the steel from coming into direct contact with moisture and oxygen, which are the main causes of corrosion. Additionally, other protective measures such as painting or coating the steel with anti-corrosion materials may also be employed to further enhance its resistance against corrosion.

- Q: How are steel coils used in the manufacturing of automotive doors?

- Steel coils are used in the manufacturing of automotive doors by being processed and shaped into sheets that are then stamped, cut, and formed to create the door's structure. The strength and durability of steel make it an ideal material for automotive doors, ensuring safety and protection for passengers.

- Q: How are steel coils used in the production of furniture components?

- Due to their strength, durability, and versatility, steel coils are frequently utilized in the manufacturing of furniture components. These coils, crafted from high-quality steel, undergo a process of uncoiling before being fed into a machine known as a stamping press. Within the stamping press, a die is employed to shape and cut the steel coil into various components necessary for furniture production, such as chair frames, table legs, or brackets. The utilization of steel coils facilitates the mass production of furniture components with uniform dimensions and exceptional accuracy. The robustness of steel guarantees that these components can withstand heavy loads, providing stability to the furniture. Additionally, steel coils possess the ability to be effortlessly molded into diverse shapes and sizes, enabling the creation of a vast array of furniture designs. Furthermore, steel coils are frequently subjected to protective treatments or coatings, such as paints or galvanization, in order to enhance their resistance to corrosion, moisture, and wear. This ensures that the furniture components possess a longer lifespan and retain their aesthetic appeal over time. In conclusion, the presence of steel coils plays a vital role in the production of furniture components, as they offer strength, durability, and versatility. They enable the mass production of precise and consistent components, while their protective coatings guarantee the durability and quality of the final furniture products.

- Q: What is the use for spring steel that take advantage of its unique properties?

- This Site Might Help You. RE: Use for spring steel? What is the use for spring steel that take advantage of its unique properties?

- Q: I am making a permanent magnet, just for fun. I am trying to find the best grade of steel to do so with.

- The type of steel you require is Steel ( Iron + Carbon, mainly.),{many different types of steel } with a high Cobalt and Nickel content. These alloyed together give the best Permanent Magnets, mainly due to their own individual magnetic properties / characteristics being retained in the Alloy. All 3 metals can be magnetised by there own, but Cobalt is known to cause cancer. Nickel, is poisonous and can also cause sever Dermatitis and the destruction of skin tissue.But when alloyed together with Iron they are pretty harmless. Interesting thing is, All of these metals (in this case Elements) can share the same Mass Number ( 60 ). And yet are totally different in their other properties beside Magnetism. Cobalt - Samarium - alloys, create some of the worlds most powerful permanent magnets. And were used in medicine, But are now superseded by Neodymium magnets which are employed instead. Edit; What you could try is, mild steel which is widely available and easily found. . The steels mentioned above are pretty exclusive materials and I personally would not know how to test for their contents, of which they are made from. Soft Iron is good for making electro-magnets if you fancy a go at making one. .

Send your message to us

Prepainted Galvanized Rolled Steel Coil/Sheet from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords