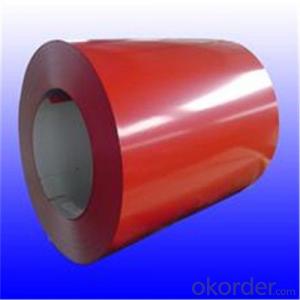

Prepainted galvanized Rolled Steel coil/Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Prepainted Galvanized Steel:

Prepainted Galvanized Steel usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final production .

Prepainted Galvanized Steel qualified with excellent decorative, formability, corrosion resistance, coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc. Which is an ideal material; for manufacturing board.

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

Applications of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images of Prepainted Galvanized Steel:

- Q: What are the different types of steel coil surface coatings?

- Steel coils can be enhanced in terms of durability, corrosion resistance, and aesthetic appearance through the use of various types of surface coatings. The most commonly employed coatings are as follows: 1. Zinc Coatings: These are widely utilized to safeguard steel against corrosion. A layer of zinc is applied to galvanized steel coils, acting as a barrier against moisture and other environmental elements. 2. Galvannealed Coatings: This type of coating combines zinc and iron, providing improved corrosion resistance and enhancing paint adhesion. It is ideal for applications that require painting. 3. Aluminum Coatings: Aluminum coatings are employed to achieve a lightweight and corrosion-resistant surface. Steel coils coated with aluminum are frequently utilized in the automotive industry for body panels and other parts that require high strength and corrosion resistance. 4. Organic Coatings: Organic coatings, typically in the form of paint or powder coatings, offer protection against corrosion. They also provide a wide range of color options for aesthetic purposes. In the construction industry, they are commonly used for roofing and cladding applications. 5. Metallic Coatings: Metallic coatings such as tin, nickel, and chromium can be applied to steel coils to confer specific properties, such as improved electrical conductivity, increased hardness, or enhanced resistance to wear and tear. 6. Ceramic Coatings: Ceramic coatings are employed to achieve high-temperature resistance and thermal barrier properties. They find application in situations where steel coils are exposed to extreme heat or in industrial processes that require thermal insulation. Each type of coating possesses unique properties and advantages, and the selection of a suitable coating depends on the specific requirements of the application. Manufacturers and engineers carefully consider factors such as cost, durability, corrosion resistance, and aesthetic appeal when deciding on the appropriate coating for steel coils.

- Q: How do you calculate the weight of a steel coil?

- In order to determine the weight of a steel coil, one must have knowledge of its dimensions and the specific gravity of the steel. The weight can be calculated using the following formula: Weight of steel coil = Length of coil (in meters) x Width of coil (in meters) x Thickness of coil (in meters) x Specific gravity of steel To begin, measure the length, width, and thickness of the steel coil in meters. It is important to ensure that all measurements are in the same unit in order to obtain accurate calculations. Next, find the specific gravity of the steel. The specific gravity is the ratio of the density of the substance to the density of water. For steel, the specific gravity is typically around 7.8. Multiply the length, width, and thickness of the coil together. This calculation will provide the volume of the steel coil in cubic meters. Lastly, multiply the volume of the coil by the specific gravity of steel to obtain the weight of the steel coil in kilograms (kg). Please note that this calculation only accounts for the weight of the steel coil and does not consider any additional factors such as the core material or any other components included in the coil.

- Q: How is the thickness of a steel coil measured?

- The thickness of a steel coil is typically measured using a gauge, which is a specialized tool specifically designed for measuring the thickness of materials. The gauge is pressed against the coil, and the reading on the gauge indicates the thickness of the steel.

- Q: How are steel coils used in the manufacturing of electrical wiring?

- Steel coils are not typically used directly in the manufacturing of electrical wiring. However, steel coils can be used in the production of wire drawing machines, which are used to stretch and shape the copper or aluminum wire used in electrical wiring.

- Q: I am reading the book The Cure For All Advanced Cancers by Hulda Regehr Clark.She writes for example: cancer can be caused by exposure to heavy metals, like nickel and chromium from stainless steel cookware. Stainless steel cookware releases chromium and nickel, two of the most carcinogenic metals.Are there any studies done measuring how much nickel and cadmium can be released from the regular use of stainless steel cookware?Is this a commonly accepted opinion that use of stainless steel cookware is dangerous?If not stainless steel, what kind of cookware to use? I heard that non-stick cookware also releases some harmful chemicals.

- No, the studies done and published in JAMA showed that the over cooking of the food MAY lead to higher incidents of SOME cancers but the cookware did not contribute. Humans do well filtering heavy metals which is why spring water tastes so good to us. This author is wrong if not she'd win a Nobel prize for finding a simple way to prevent cancer.

- Q: What are the different types of steel coil transport methods?

- There are several different types of steel coil transport methods, including trucking, rail transportation, and sea freight. Trucking involves using flatbed trucks or specialized trailers to transport steel coils over short distances. Rail transportation utilizes flatcars or specialized railcars to transport steel coils over long distances. Sea freight involves shipping steel coils in containers or on specialized vessels across international waters.

- Q: How do steel coils contribute to the manufacturing of HVAC systems?

- Steel coils play a crucial role in the manufacturing of HVAC systems. These coils are typically made from high-quality steel, which offers exceptional strength, durability, and heat resistance. One of the main uses of steel coils in HVAC systems is for heat exchangers. Heat exchangers are vital components that facilitate the transfer of heat between two different mediums, usually air and a refrigerant. In an HVAC system, steel coils are used in both the evaporator and condenser coils. The evaporator coil absorbs heat from the air inside a building, while the condenser coil releases heat to the outside environment. These coils are designed with numerous tubes that are coiled and connected with fins. The steel construction of these coils ensures that they can withstand high-pressure environments and resist corrosion, ensuring long-term reliability and efficiency of the HVAC system. Steel coils also contribute to the overall structural integrity of HVAC systems. They are commonly used in the fabrication of ductwork, which is responsible for distributing conditioned air throughout a building. The strength and rigidity of steel coils allow ductwork to maintain its shape and structural integrity under various conditions, including high air pressure and temperature fluctuations. Furthermore, steel coils are often used in the fabrication of HVAC system cabinets and enclosures. These cabinets house various components of the system, such as compressors, fans, and control panels. The robustness of steel coils ensures that the cabinets can withstand external forces, protect the internal components, and provide a secure housing for the entire HVAC system. In summary, steel coils are essential components in the manufacturing of HVAC systems. Their strength, durability, and heat resistance make them ideal for heat exchangers, ductwork, cabinets, and enclosures. By utilizing steel coils, HVAC manufacturers can produce systems that efficiently and effectively regulate temperature, improve indoor air quality, and provide comfort in various residential, commercial, and industrial settings.

- Q: How do steel coils contribute to sustainability in manufacturing?

- Steel coils contribute to sustainability in manufacturing in several ways: 1. Recyclability: Steel is one of the most recycled materials in the world, with a recycling rate of over 90%. Steel coils are made from recycled steel and can be recycled again at the end of their life cycle. This reduces the need for extracting raw materials, conserves natural resources, and reduces energy consumption and greenhouse gas emissions associated with steel production. 2. Durability: Steel is known for its strength and durability. Steel coils are designed to withstand heavy loads, extreme temperatures, and harsh environmental conditions. This means that products made from steel coils, such as automotive parts, construction materials, and appliances, have a longer lifespan, reducing the need for frequent replacements and minimizing waste. 3. Energy efficiency: Steel coils are used in various manufacturing processes, such as stamping, forming, and welding. These processes require less energy when working with steel coils compared to other materials. Steel's high strength-to-weight ratio allows for the production of lightweight yet strong components, reducing energy consumption during transportation and improving fuel efficiency in vehicles. 4. Reduced emissions: Steel coils contribute to sustainability by helping manufacturers reduce their emissions. Steel is a low-carbon material, and its production emits fewer greenhouse gases compared to other materials like aluminum or plastics. By using steel coils, manufacturers can reduce their carbon footprint and contribute to climate change mitigation efforts. 5. Circular economy: Steel coils are a key component in the circular economy, which aims to minimize waste and maximize resource efficiency. Steel coils can be easily recycled and reused, ensuring that they remain in the production cycle for a longer time. This reduces the need for virgin materials and promotes a more sustainable and circular approach to manufacturing. In conclusion, steel coils contribute to sustainability in manufacturing by being recyclable, durable, energy-efficient, emission-reducing, and promoting a circular economy. By choosing steel as a material and utilizing steel coils, manufacturers can make significant strides towards reducing their environmental impact and fostering a more sustainable manufacturing industry.

- Q: How are steel coils used in the production of storage tanks and silos?

- Steel coils are an essential component in the production of storage tanks and silos due to their strength and durability. These coils are typically made from high-quality steel and are processed through various manufacturing techniques to attain the desired thickness and shape. In the production process, steel coils are first uncoiled and then cut into specific sizes and lengths to meet the requirements of the storage tank or silo design. The coils are then shaped into cylindrical sections, using bending and rolling machines, to create the main body of the tank or silo. Once the desired shape is achieved, the coils are welded together to form a continuous and secure seam. This welding process ensures that the tanks and silos are leak-proof and can withstand the pressure exerted by the stored materials. Furthermore, steel coils also play a crucial role in reinforcing the structure of storage tanks and silos. They are often used to create the roofs, bottoms, and other structural components of these storage units. The strength and resilience of steel make it ideal for withstanding the weight of the stored materials and any external forces that may be exerted on the tank or silo. Additionally, steel coils can be coated or treated with protective materials to enhance their resistance to corrosion and extend their lifespan. This is particularly important for storage tanks and silos that are used to store corrosive substances or are exposed to harsh environmental conditions. Overall, steel coils are a fundamental element in the production of storage tanks and silos, providing the necessary strength, durability, and structural integrity required for these storage units.

- Q: I have steel on my 9.5 ti now.. ive heard about synthetic being stronger but it snaps when it hits something sharp.. opinions people?

- Steel is more dangerous, both in a fatal metal whip way and a metal splinters in my hand way. Steel weighs more. So why would anyone continue to use steel? Cost and care. Care: Steel can sit for years without having to worry about dry rot (as long as it's not out in too horrible of weather conditions). Steel is much more resistant to fraying. You don't have to baby steel so much to keep it in good conditions. Cost: As of right now, steel is less than half the cost of synthetic. A synthetic rope can cost as much as many electric winches which include a steel cable. I find that I don't use my winch nearly enough to warrent the extra care or cost of a synthetic. The weight savings would be nice, but I kind of ruined that a long time ago with the winch bumper, rock sliders, plate steel fenders/flares, belly armor and frame plating.

Send your message to us

Prepainted galvanized Rolled Steel coil/Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords