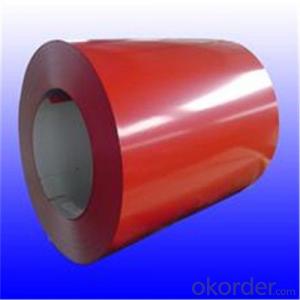

Prepainted Galvanized Rolled Steel Coil/Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Prepainted Galvanized Steel:

Prepainted Galvanized Steel usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final production .

Prepainted Galvanized Steel qualified with excellent decorative, formability, corrosion resistance, coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc. Which is an ideal material; for manufacturing board.

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

Applications of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images of Prepainted Galvanized Steel:

- Q: I saw an amazing flamenco player, however i have a steel string guitar, where he had a nylon stringed one. So i was wndering if its possible to play flamenco songs on the steel string guitar, and where could i find a tab for it? are there tabs for rasegueados?

- Well, you couldn't play traditional flamenco on a steel string guitar, that's for sure. What you could do is learn some flamenco chords and chord progressions. One problem is that a lot of flamenco techniques on a steel string guitar -- rasgueado, for example -- will literally sand your right hand fingernails down to the nub. It's not going to be pretty, and will probably be painful. Even on a flamenco guitar I protect my right hand nails with a thin coat of super glue. Also, the fingerboard of a flamenco guitar is wider than that of a steel string guitar. That's because many of the notes played in flamenco are actually played with the left hand, not the right hand - lots of hammer ons and pull offs. You can do that higher up the neck on an steel string guitar, but it would be hard to do that in first position on that guitar. Anyway, yes, to a small extent you could conceivably do something that has a flamenco sound on a steel string guitar. But why? You can get a great student model flamenco guitar from Yamaha. It's only $350. Then, you need a teacher. Flamenco is difficult to learn (I've been at it for ten years) and it's important to learn from an instructor who can teach you the correct techniques. Otherwise, you just have to learn everything all over again when you finally do take lessons. Intermediate and advanced students can learn from a video, but beginners really need face time with an instructor. Best wishes.

- Q: How are steel coils used in the production of agricultural irrigation systems?

- Steel coils are used in the production of agricultural irrigation systems as they are often used to manufacture pipes, tubing, and other structural components that are necessary for the efficient distribution of water to crops. The strength and durability of steel coils make them ideal for withstanding the high pressure and harsh conditions often encountered in irrigation systems, ensuring a reliable and long-lasting solution for farmers.

- Q: What are the different types of surface treatments for steel coils?

- There are several types of surface treatments for steel coils, including galvanizing, painting, and coating. Galvanizing involves applying a layer of zinc to protect the steel from corrosion. Painting involves applying a layer of paint to provide both corrosion resistance and aesthetic appeal. Coating involves applying a thin layer of protective material, such as polymer or epoxy, to enhance the steel's durability and resistance to corrosion. These surface treatments are chosen based on the specific requirements of the steel coils and the desired end-use applications.

- Q: What are the main factors that affect the flatness of steel coils?

- The main factors that affect the flatness of steel coils include the quality of the raw material used, the thickness and width of the coil, the temperature and humidity during the manufacturing process, the tension applied during coiling, and the cooling and leveling processes employed.

- Q: How are steel coils packaged for shipment?

- Steel coils are typically packaged for shipment by being tightly wound, strapped with steel bands, and then secured onto wooden pallets. The coils are often covered with protective wrapping or placed inside steel containers to ensure safe transportation and prevent damage or corrosion.

- Q: What are the common applications of steel coils?

- Steel coils have a wide range of applications, commonly used in industries such as automotive, construction, manufacturing, and appliances. They are utilized for making various products including automobiles, pipes, electrical appliances, roofing, and packaging materials.

- Q: What are the key players in the steel coil manufacturing industry?

- Large multinational companies with significant market share and influence dominate the steel coil manufacturing industry. Among the prominent players are: 1. ArcelorMittal, the world's largest steel producer, operates in over 60 countries and offers a diverse product portfolio. 2. Nippon Steel Corporation, a leading Japanese steelmaker, holds a prominent position in the global steel coil manufacturing market, particularly in the automotive and construction sectors. 3. POSCO, based in South Korea, is renowned for its high-quality steel products and advanced technology in steel coil manufacturing. 4. Baosteel Group Corporation, the largest steel manufacturer in China and globally, boasts a vast range of steel products, including steel coils, and excels in research and development capabilities. 5. Thyssenkrupp AG, a German multinational conglomerate, plays a significant role in the steel coil manufacturing industry, focusing on innovation and sustainability across a diverse product range. 6. United States Steel Corporation, a leading American steel producer, holds a crucial position in the steel coil manufacturing industry, particularly in the automotive, construction, and energy sectors. 7. JFE Holdings, Inc., a Japanese steel conglomerate, is a key player in the steel coil manufacturing industry, known for its customer-oriented approach and high-quality steel products. These companies represent a fraction of the key players in the steel coil manufacturing industry, as numerous others contribute to this sector. The industry is highly competitive, and these companies consistently strive to innovate, enhance efficiency, and meet the evolving demands of the market.

- Q: i got a strip of steel from lowes how to sharpen it its not that thick its kinda slim but its heavyish its around 4'2 feet tall i cant get a whetstone or anything elsei have a brick , sand paper , and a hammer and some charcoal i was heating it up and trying to pound a edge into italso how to cut the steel to make a pointy curved tip any help appreciated and please tell me easy methodsplus its not sharp at all

- Bench grinder, Dremel Hand Grinder

- Q: How are steel coils used in the production of electronic devices?

- Steel coils are used in the production of electronic devices in a variety of ways. One common use is in the manufacturing of transformers and inductors, which are crucial components in many electronic devices. Transformers and inductors consist of a coil of wire wound around a core, and steel coils are often used as the core material due to their magnetic properties. The steel coils used in these components help to enhance the magnetic fields generated by the coils, enabling efficient energy transfer and voltage regulation. The magnetic properties of steel, such as its high permeability and low hysteresis loss, make it an ideal material for these applications. Additionally, steel coils are also used in the production of printed circuit boards (PCBs). PCBs are the backbone of most electronic devices and consist of a flat board made of non-conductive material, such as fiberglass, with a thin layer of copper traces etched onto it. These copper traces form the electrical connections between various components on the board. Steel coils are used in the production of PCBs as part of the fabrication process. They are typically used to create the stencils that are used to apply solder paste onto the board before component placement. The steel coils are laser-cut to create precise stencil patterns, allowing for accurate and consistent solder paste application. In summary, steel coils play a vital role in the production of electronic devices. They are used in the manufacturing of transformers and inductors, where their magnetic properties enhance energy transfer and voltage regulation. Steel coils are also utilized in the fabrication of PCBs, where they are used to create stencils for solder paste application. Overall, the use of steel coils helps ensure the efficient and reliable operation of electronic devices.

- Q: Can steel coils be coated with impact-resistant materials?

- Yes, steel coils can be coated with impact-resistant materials. The coating process involves applying a layer of impact-resistant material onto the surface of the steel coils to enhance their durability and protection against impacts or damages. This coating can provide additional strength and resistance, making the coils suitable for various applications requiring impact resistance.

Send your message to us

Prepainted Galvanized Rolled Steel Coil/Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords