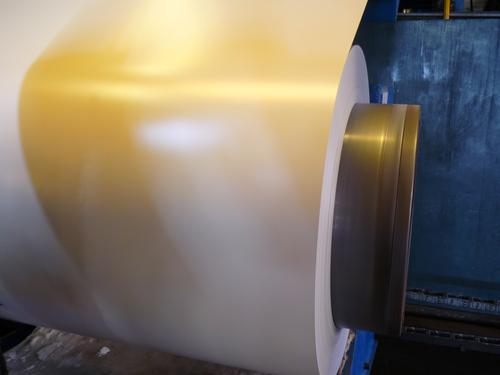

Prepainted Galvanised Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prepainted Galvanized Steel Coils

With galvanized steel as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Brand Name: OKLSTEEL

Specifications Of Prepainted Galvanized Steel Coils

Thickness 0.186-0.8mm (BMT) Width 1000-1250mm |

Zinc Coating 80-275g/m2 |

Color According to RAL color fan or as per request |

Internal Diameter 508mm or 610mm |

Coil Weight 4-8MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD,S280GD,S350GD,CS,FS,SS |

Chemical Composition OfPrepainted Galvanized Steel Coils

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data OfPrepainted Galvanized Steel Coils

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Applications Of Prepainted Galvanized Steel Coils

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

Packaging & Delivery Of Prepainted Galvanized Steel Coils

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Production Flow Of Prepainted Galvanized Steel Coils

Production flow of hot sell prepainted galvanized steel include dual uncoiler,stitcher, bridles, entry accumulater, degreasing & chemical section, prime coater, prime oven, prime water quench, finish coating, finish back coater, finish oven, finish water quench, exit accumulater and recoiler.

- Q: I want to know because I'm going to Hershey Park on Wednesday and Steel Force looks about the same size, so, I wanted to know. It's not that Steel Force is too big for me.

- steel force breaks the 200ft mark and is a steel out and back roller coaster. Tidal force is a water ride that is about 100 ft tall. If you can do Steel Force then you should be able to handle anything at Hersheypark. the on;y ride they have bigger is the Kissing Tower

- Q: What is the yield strength of steel coils?

- The yield strength of steel coils can vary depending on the specific grade and composition of the steel. However, on average, the yield strength of steel coils typically ranges from 250 to 350 megapascals (MPa).

- Q: How do steel coils contribute to the HVACR equipment industry?

- Efficient heat transfer and effective functioning of HVACR systems are crucial roles played by steel coils in the HVACR equipment industry. These coils, made of high-quality steel, are integral components of air conditioners, heat pumps, refrigerators, and boilers. Facilitating heat transfer is one of the primary functions of steel coils in HVACR equipment. Designed to efficiently transfer heat between the refrigerant and the surrounding air or water, these coils utilize a large surface area and good thermal conductivity. As a result, HVACR equipment can effectively cool or heat a given space, ensuring optimal energy efficiency and reducing operating costs in residential and commercial applications. In addition to heat transfer, steel coils contribute to the overall durability and longevity of HVACR equipment. The use of corrosion-resistant steel in these coils helps prevent damage from moisture and other environmental factors. This reliability is particularly important as HVACR systems often face harsh conditions and must operate continuously to maintain comfortable indoor environments. Furthermore, steel coils offer versatility and customization options to meet specific HVACR requirements. Manufacturers can vary the size, shape, and configuration of the coils to fit available space and optimize performance. This flexibility enables efficient integration of steel coils into different HVACR equipment, ensuring they meet the specific heating and cooling needs of diverse environments. In conclusion, steel coils are indispensable in the HVACR equipment industry. They enable efficient heat transfer, enhance durability, and offer customization options, ensuring effective functioning and energy efficiency of HVACR systems. Manufacturers can provide reliable and long-lasting solutions for heating, ventilation, air conditioning, and refrigeration needs in residential and commercial settings by incorporating high-quality steel coils into their products.

- Q: It seems that steel would be stonger and more stable than wood, fire resistant, and better for the environment, so why are most homes wood-framed rather than steel-framed?

- Because it's always been done that way. Never underestimate inertia when asking why new materials/techniques are not adopted. Besides, the cost does not give steel a clear advantage. You can drive a nail anywhere into a stud. With steel, you have to drill your holes precisely.

- Q: How are steel coils used in the manufacturing of suspension arms?

- Steel coils are used in the manufacturing of suspension arms as they provide the necessary strength and flexibility to absorb shocks and vibrations, ensuring a smooth ride. These coils, known as coil springs, are typically mounted between the suspension arm and the vehicle's chassis, supporting the weight of the vehicle and allowing for controlled movement and suspension travel. By compressing and expanding, steel coils help absorb the impact of bumps and uneven road surfaces, providing stability and improving overall handling and comfort.

- Q: How are steel coils used in the production of automotive frames?

- Steel coils are used in the production of automotive frames by being unwound and fed into a machine that shapes and welds the steel into the desired frame structure. The high-strength and durability of steel make it an ideal material for automotive frames, providing structural integrity and safety to the vehicle.

- Q: Can I ever get my classical guitar reinforced so it can have steel strings on it?

- describes the differences in construction of classical nylon string guitars and steel string guitars--like I said, it would involve reconstruction of more than just a neck

- Q: What are the common coil edge finishes?

- The common coil edge finishes include mill edge, slit edge, and deburred edge.

- Q: How are steel coils used in the manufacturing of suspension systems?

- Steel coils are commonly used in the manufacturing of suspension systems as they provide the necessary support and flexibility to absorb shocks and vibrations. These coils are typically shaped into springs and placed in the suspension system of vehicles, helping to maintain stability, improve handling, and ensure a smooth ride by absorbing the impact from uneven surfaces on the road.

- Q: I have taylormade burner steel irons and I was wondering what would the flex of steel be if you were to compare it to graphite shafts, like regular, stiff, super stiff, etc...THANKS!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- If i understand you correctly, i think you misunderstand shafts. Steel shafts vs. graphite shafts these days is more of a competition of weights, not flexibility. Both steel and Graphite have different flex profiles available from Ladies (L) to super stiff (X). Graphite may feel a little more whippy than steel because of the lighter weight. Shafts will vary by company as well. Stiff from True temper may not be as stiff as one from Aldila, or vice verse. You can also make a shaft play stiffer or more flexible by where you cut the length. This is called tipping. Take more from the bottom and it will be stiffer, more from the grip end and it will play more flexible.

Send your message to us

Prepainted Galvanised Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords