Prepainted Aluminum Zinc Rolled Coil For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

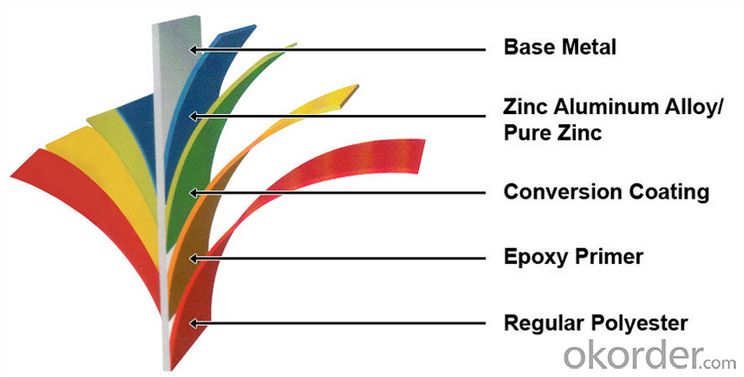

Structure of Prepainted Aluminum Zinc Rolled Coil For Construction

Description of Prepainted Aluminum Zinc Rolled Coil For Construction

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Aluminum Zinc Rolled Coil For Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Aluminum Zinc Rolled Coil For Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Prepainted Aluminum Zinc Rolled Coil For Construction Images

Specifications of Prepainted Aluminum Zinc Rolled Coil for Construction

Commodity | Hot Dipped Galvalume Steel Coil/Sheet | |||

Standard | JIS G3321 / ASTM A792M / EN10215 | |||

Grade | SGLCC/SGLCD/SGLC490/SGLC570/CS TypeA,B,C/DS/255/DX51D+AZ/DX52D+AZ/S250GD+AZ/S350GD+AZ/S550GD+AZ | |||

Chemical Composition | 55%Al,43.5%Zn,1.5%Si | |||

Thicknees | 0.16-2.0 mm | Width | 600-1250mm | |

Aluzinc Coating | AZ30-AZ200 g/m 2 | Coil Weight(Min or Max) | 3-8 tons | |

Coil Inner Diameter | 508mm | 610mm | Coil Outer Diameter(Max) | |

Surface Treatment: | <1>Oiled | <2>Unoiled | <3>Slightly Oil | <4>Chromated Passivated |

<5>Skin Pass | <6>Anti Finger Print | |||

Surface Structure | Mini/Small Spangle | |||

Futher Process | Cut coil into Sheet | Corrugated Roofing Sheet | ||

FAQ of Prepainted Aluminum Zinc Rolled Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I have been searching on pots and pans, how can I find out if it's really stainless steel, someone told me if a magnet sticks to it it's real stainless steel is this true?

- Some types of stainless are magnetic and some are not. being magnetic isn't a reliable way to tell the difference. In fact, only the cheapest pots would be made out of grades of stainless that are magnetic. Stainless pots/pans are generally made of non-magnetic types, but then again, aluminum isn't magnetic either. Aluminum and stainless are superficially very similar.

- Q: I live in Dubai. I want to make a damascus steel sword and have no idea where to get the steel or what sort of steel I should get.First to adress the access of my steel...I need to get some low carbon and high carbon steel for the Damascus....what sort of steel is recommended for this? Also where would I be able to get my hands on it (Internet options e.g websites or locations)THANKS

- hI Jordan damascus steel is not actually a steel it is a composite material like the damascus rifle barrels the Afghan's use it is made from wire wrapped around an inner mandrel the beaten on an anvil till all the wire becomes one so it is several types of iron and steel beaten together and forged to produce it so it is not something you can actually buy as a material the tribesmen that produce these swords have these secret methods of doing this so there is the first problem. it is not like cast steel which is what most swords are made of it is far more complex in it's construction. so you may need to do a lot of research to find out how. what is a similar idea is the SAMURAI sword that is made up of combining different steels together and forged into a very sharp and capable killing blade.

- Q: I want to experiment with making steel and want to especially make it stronger. And also I want to know if its possible to turn a meteorite into steel?

- To add to Alex's good answer... ASM Intl now has a book titled Steel Metallurgy for Non-Metallurgist. You can turn metallic meteorites into steel if you add the right amount of Fe and C. That won't make it the strongest but it is possible. I don't think you want the strongest exactly. In general and with swords in particular, you want to be pretty specific about exactly what physical properties you want. Strength and ductility typically vary inversely to each other, higher stength, lower ductility, or lower strength, higher ductility. The issue is related to the idea of a diamond sword. It would be nice and hard but it would probably shatter the first time you stuck anything with it. Swords need a combination of properties, hard so it holds a sharp edge, and tough so it does not fracture, strong so it can be light enough to swing.

- Q: What are the different methods of shearing steel coils?

- There are several different methods of shearing steel coils, each offering its own unique advantages and disadvantages. Some of the most common methods include: 1. Guillotine Shearing: This method involves using a guillotine-like machine with a blade that moves vertically to cut through the steel coil. Guillotine shearing offers high efficiency and accuracy, making it suitable for large-scale industrial production. However, it may cause deformation or burrs on the cut edges. 2. Rotary Shearing: In rotary shearing, a set of rotating blades is used to cut through the steel coil. This method allows for continuous cutting, making it ideal for high-speed production lines. It provides a clean and precise cut, but it requires regular maintenance and sharpening of the blades. 3. Slitting: Slitting involves passing the steel coil through a set of circular blades that make multiple parallel cuts. This method is commonly used to produce narrower strips from wider coils. It offers high precision and can produce multiple strips simultaneously. However, slitting may cause edge burrs or camber on the strips. 4. Laser Cutting: Laser cutting uses a high-powered laser beam to melt or vaporize the steel coil along a pre-determined path. This method offers exceptional precision and can cut complex shapes or patterns. It is commonly used for specialized applications where accuracy is crucial, although it can be relatively expensive. 5. Waterjet Cutting: Waterjet cutting utilizes a high-pressure stream of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can handle various materials and thicknesses. It is especially useful for cutting heat-sensitive materials or for applications requiring minimal distortion. 6. Plasma Cutting: Plasma cutting involves ionizing a gas to create a plasma arc that melts and blows away the steel coil. This method is fast and efficient, suitable for cutting thick steel coils. However, it may produce a wider heat-affected zone compared to other methods. 7. Electrical Discharge Machining (EDM): EDM uses electrical discharges to erode the steel coil and create the desired shape. This method is commonly used for intricate or delicate cutting tasks that require high precision. It is particularly effective for hard materials. Each method of shearing steel coils has its own set of advantages and limitations, and the choice depends on factors such as the required precision, speed, material thickness, and the desired end-product.

- Q: How are steel coils processed for different finishes?

- Steel coils can be processed for different finishes through various methods. One common process is called coil coating, where the steel coil is cleaned, primed, coated, and cured to achieve a desired finish. This process includes removing any contaminants from the surface of the coil, applying a primer to enhance adhesion, and then coating it with a specific paint or coating material. The coated coil is then cured at high temperatures to ensure proper adhesion and durability. Another method for processing steel coils is through galvanization. In this process, the steel coil is coated with a layer of zinc to protect it from corrosion. This can be done through hot-dip galvanization, where the coil is immersed in a bath of molten zinc, or through electro-galvanization, where a thin layer of zinc is electroplated onto the coil. The galvanized finish provides excellent corrosion resistance and can be further processed to achieve different aesthetic finishes. Additionally, steel coils can be processed for different finishes through various surface treatments. This may involve processes such as pickling, where the coil is treated with an acid solution to remove scale and impurities, or mechanical treatments like brushing or grinding to achieve a desired texture. These surface treatments can be followed by applying a protective coating or paint to enhance the appearance and durability of the coil. Overall, the process of achieving different finishes on steel coils involves a combination of cleaning, coating, curing, and surface treatments. The choice of specific methods depends on the desired finish and the intended application of the steel coil.

- Q: Why cold rolled stainless steel sheet is lower than cold rolled stainless steel coil?

- 304 stainless steel coil 2.0*1219*C spot price 18 thousand and 100 / ton, general tolerance at about 1.8mm.Coil price * actual thickness / reference thickness = flat price1.81*1.8/2=16.29

- Q: ex: boat hull made out of steel

- egg yolk. it really works. i know this because i built a surfing bicycle (yeah) that had steel on it.just let the steel soak in the yolk for about 3-4 hours and let it dry in a dark area. this will work.

- Q: What are the different types of steel coil finishes?

- There are several different types of steel coil finishes, including mill finish, galvanized finish, painted finish, and stainless steel finish.

- Q: How do steel coils contribute to the construction equipment industry?

- Steel coils are essential in the construction equipment industry as they are used to manufacture various components like beams, plates, and tubes. These coils provide the necessary strength and durability needed for constructing heavy machinery and equipment. Additionally, steel coils are also utilized in the fabrication of structural frameworks, reinforcing bars, and other critical parts, ensuring the integrity and safety of construction equipment.

- Q: What is the role of steel coils in the automotive industry?

- Steel coils play a crucial role in the automotive industry as they are used to manufacture various components and parts of vehicles, including body panels, frames, chassis, and suspension systems. The high strength and durability of steel make it an ideal material for ensuring structural integrity and safety in automobiles. Additionally, steel coils offer cost-effectiveness, versatility, and the ability to withstand extreme conditions, making them an essential component in the production of cars and trucks.

Send your message to us

Prepainted Aluminum Zinc Rolled Coil For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords