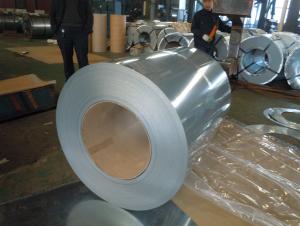

Prepaint Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method), and after roasting and cooling. PPGI is light, beautiful and has good corrosion resistant performance, can be directly processed also, ppgi provides the construction, shipbuilding, vehicle manufacturing, furniture industry, and electrical industry a new material, while ppgi has good effects on the areas of replacing wood with steel, efficient construction, energy saving, prevent pollution etc.

Base material: | hot dipped galvanized steel or Aluzinc Steel |

Standard: | JIS, SGCC, EN, ASTM |

Width: | 800 -1250mm |

Width Tolerance: | within 5mm |

Thickness: | 0.20 - 1.20mm |

Thickness Tolerance: | within 0.2MM |

Performance: | Smooth or Matte or anti-scratch |

Color: | according to RAL standard |

Lacquer Coating thickness: | according to customer needs |

Supply capacity: | 5000 Metric Ton per month |

- Q: What are the common methods of packaging steel coils for transportation?

- There are several common methods of packaging steel coils for transportation. One widely used method is to use steel strapping or bands to secure the coils together. This method involves tightly wrapping the coils with steel bands and securing them with metal buckles or seals. The strapping helps to keep the coils in place and prevents them from shifting or rolling during transportation. Another common method is to use wooden pallets or skids to stack and transport the steel coils. The coils are placed on the pallets and secured with steel strapping or bands. This method provides stability and allows for easy handling and loading onto trucks or other transportation vehicles. Some steel coils are also packaged in wooden crates or boxes. These crates are typically made of strong and durable wood and are designed to protect the coils from external impacts or damage during transportation. The crates are often reinforced with steel bands or strapping to provide additional strength and stability. In addition to these methods, some steel coils are packaged in specialized containers or units. These containers are specifically designed to hold and secure steel coils for transportation. They often have built-in mechanisms or features that make loading and unloading the coils easier and safer. It is important to note that the specific method of packaging steel coils for transportation may vary depending on factors such as the size and weight of the coils, the mode of transportation, and any specific requirements or regulations in place.

- Q: How are steel coils used in the manufacturing of engine mounts?

- Steel coils are commonly used in the manufacturing of engine mounts to provide durability, strength, and flexibility. These coils are typically designed to absorb and dampen vibrations, shocks, and movements generated by the engine during its operation. By integrating steel coils into the engine mount design, manufacturers can ensure better stability, improved performance, and reduced noise levels in vehicles.

- Q: 911 conspiacy theorists. Can fire melt steel?

- So does fuel also generate timed explosions that were heard by firemen? Why do we see melting steel that looks like thermite burning? Does the jet fuel also destroy the entire 80 stories of steel support structure as well? (This is required to account for the free-fall speed of the collapse of three buildings. That's right, three buildings collapsed at near free-fall speeds in NYC in the WTC complex.) The government's conspiracy theory is totally inconsistent with the facts. The only theory that has coherence at the moment is the demolition theory presented by Professor Steven Jones of BYU (Physics). I've seen no credible challenges to the 13 points he presented in an academic paper on this topic. I'd very much like to see a credible explanation for the free-fall collapse of all three buildings.

- Q: Hi my dad bought a stain steel refridg. yesterday, and we went to clean it and it looks all streaky and gets finger prints and stuff on it too easily we used mr clean multisurface cleaner and it didnt work to well is there a certain type of cleaner we are supposed to use?

- buy stainless steel wipes at the grocery store. they work great.

- Q: PLS tell me all Foam Steel Characteristics and use?Thanks

- Foam steel [often steel foam] is used in applications that require light weight but high rigidity and strength. Watertight doors on modern ships are often made of foam steel. Pressure doors on aircraft are possible uses. As we keep striving for lighter weights in cars, foam steel might have some useful applications in bodies. There is a technical paper online that is in .pdf format that has a good discussion of the process and characteristics of foam steel.

- Q: How are steel coils used in the production of electrical systems?

- Steel coils are used in the production of electrical systems as they serve as the core component of transformers and inductors. They provide a magnetic field necessary for the efficient functioning and transformation of electrical energy.

- Q: So, I'm doing this project for my chemistry class and I need to explain the raw materials in which paper slips are made of. I'm not really sure if galvanized steel is. If not, can someone PLEASE tell me what raw materials are metal paper clips made of???

- As a specially coated type of steel, galvanized metal enjoys a great reputation as being an ideal building product to use for any type of structure that is expected to stand for many years. Here are some basics about how galvanized steel is created, as well as how it can be used in various building projects. Galvanized metal is simply steel in some form that has received a thin coating of zinc oxide. The purpose of the zinc is to protect the steel from elements that normally would lead to oxidation, corrosion and the eventual weakening of the steel. In this sense, the zinc coating acts as what is called a sacrificial anode. In other words, the zinc will protect the steel from corrosion by acting as a barrier between the steel and the corrosive agent, at least until the zinc coating has been completely oxidized. Galvanized metal can be made into supports, girders and even into sheets of metal that can be used in all sorts of construction and building projects.

- Q: I was wondering because i just watched an episode of build it bigger on the discovery channel about the uss George bush, and when they were discribing it they said it was 500 tons of steel and 47,000 tons of aluminum. this kinda struck me as odd because i thought that it was mostly made of steel. and i would think that even if it was mostly aluminum, that the hull would be steel. and i think the hull would weigh more than 500 tons.

- The hull is steel the island is an aluminum composite. Carriers are 100,000 tons of Diplomatic Diplomacy!

- Q: What are the common coil widths available for steel coils?

- The common coil widths available for steel coils vary depending on the specific application and industry requirements. However, there are several standard coil widths that are commonly available in the steel industry. These include: 1. 24 inches (approximately 610 mm): This is a common coil width used for various applications, including automotive manufacturing, construction, and general engineering. 2. 36 inches (approximately 914 mm): This wider coil width is often used in the construction industry for roofing and siding materials. 3. 48 inches (approximately 1219 mm): This wider coil width is commonly used in manufacturing processes where larger steel sheets are required, such as in the production of appliances, HVAC systems, or industrial machinery. 4. 60 inches (approximately 1524 mm): This wider coil width is typically used for specialized applications in industries such as automotive manufacturing, aerospace, or shipbuilding. It is important to note that while these are some of the more common coil widths, steel coils can be produced in custom widths to meet specific customer requirements. Additionally, the availability of coil widths may vary depending on the steel mill or supplier.

- Q: Bronze came before steel, right? thanks

- Bronze The earliest surviving iron artifacts, from the 5th millennium BC in Iran and 2nd millennium BC in China, were made from meteoric iron-nickel. By the end of the 2nd millennium BC iron was being produced from iron ores from South of the Saharan Africa to China. Steel (with a smaller carbon content than pig iron but more than wrought iron) was first produced in antiquity. New methods of producing it by carburizing bars of iron in the cementation process were devised in the 17th century. In the Industrial Revolution, new methods of producing bar iron without charcoal were devised and these were later applied to produce steel. In the late 1850s, Henry Bessemer invented a new steelmaking process, involving blowing air through molten pig iron, to produce mild steel. This and other 19th century and later processes have led to wrought iron no longer being produced. The earliest tin-alloy bronzes date to the late 4th millennium BC in Susa (Iran) and some ancient sites in China, Luristan (Iran) and Mesopotamia (Iraq).

Send your message to us

Prepaint Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords