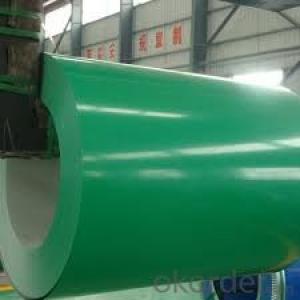

Pre-Painted Galvanized Steel Coil/Construction Purposes/Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Product Description

| PRODUCT SPECIFICATION |

Commodity | Prepainted galvanized steel coil |

Base Metal |

|

| 0.16 TO 1.00 mm |

Width | 600 TO 1500 mm |

Coil ID | 508 / 610 mm |

Type | coil/sheet/strips |

|

|

| Soft, medium,full hard |

Zinc Coating | Z 40-275 gsm, AZ 40-180 gsm or as customer requirements |

Types of top coating |

|

| As per RAL shades/customer requirements. |

Surface Finishes | Glossy and Matte |

Price: | US $600-800 / Metric Ton |

Slits | 37mm and above |

Standards | AISI, ASTM, BS, DIN, GB, JIS |

Transport | By bulk or container |

Packing | Standard packing or at buyer's requirement |

Applications:

Pre-painted steel metal products are used in a vast array of applications including:

1.construction industry

2. household appliances

3.automotive

4.industrial applications

5.packaging

FAQ

What is the validity of your quotation?

Normally 2 days.

- Q: in a lab at school we did heat treatment of steelwhat are the possible phases present in the steel sample in as-received, as-quenched and as-tempered conditions? specifically when is it ferrite, austenite and pearliteis the steel originally in the ferrite phase? then when headed turns into austenite and when quenched martensite is formed and when tempered cermentite is formed...........where is pearlite involved and am i correct about the ferrite?

- hey from what i learned in uni last sem, steel is originally ferrite form at first at room conditions. it will undergo poly morphic transformation to become FCC structure austenite form at 912 degree celcius. under conditions, it can become pearlite (which is a combination of ferrite and cementite) or bainitie( a finer form of pearlite). queching conditions to room temperature will form martensite which is the strongest but brittle steel form. tempered cementite is formed when we quench it and then raise temperatures before sir cooling. hope it helps, pls vote me best answer is i deserve it. thanks

- Q: What are the different types of coil edge trimming machines?

- In the market, one can find a variety of coil edge trimming machines. These machines are specifically designed for the purpose of trimming the edges of coils or rolls made from different materials like metal, paper, plastic, or fabric. Each machine type possesses unique features and capabilities to cater to specific trimming needs. 1. Manual Edge Trimmers: These machines require manual operation where an operator feeds the coil and trims the edges using a cutting tool or blade. Manual edge trimmers are suitable for trimming applications with low volumes and rely on the skill and precision of the operator. 2. Semi-automatic Edge Trimmers: These machines offer automated feeding mechanisms to assist in the coil feeding process. However, the operator still performs the trimming manually using a cutting tool. The feeding mechanism reduces manual effort and increases productivity. 3. Automatic Edge Trimmers: These fully automated machines require minimal operator intervention. Equipped with advanced sensors and controls, they ensure precise and consistent trimming of coil edges. Automatic edge trimmers can handle high volumes of coils and are often integrated into production lines for continuous trimming operations. 4. Rotary Blade Edge Trimmers: These machines utilize high-speed rotating blades to trim coil edges with precision. Commonly used for plastic or fabric coils, they provide clean and smooth cuts. 5. Guillotine Edge Trimmers: These machines employ a guillotine-like cutting mechanism to trim coil edges. The cutting blade moves vertically, resulting in straight and accurate cuts. Guillotine edge trimmers are suitable for trimming metal or paper coils. 6. Laser Edge Trimmers: These machines adopt laser technology to trim coil edges. The laser beam ensures clean and precise cuts, making them ideal for delicate or high-value materials. The choice of the appropriate coil edge trimming machine depends on the specific requirements of the application. Factors such as material type, coil dimensions, trimming precision, and production volume should be taken into consideration. Each machine type has its own advantages and limitations.

- Q: How are steel coils used in the packaging industry?

- Steel coils are used in the packaging industry to create durable and sturdy packaging materials, such as metal strapping and steel bands. These coils are commonly used to secure and protect heavy or bulky items during transportation, ensuring that the packaging remains intact and resistant to damage.

- Q: How are steel coils used in the production of bridges and infrastructure?

- Steel coils are used in the production of bridges and infrastructure as they are rolled into different shapes and sizes to form the structural components. These coils are then used to create beams, girders, and columns, providing strength and support to the structures. The flexibility and durability of steel allow for the construction of bridges and infrastructure that can withstand heavy loads, extreme weather conditions, and long-term use.

- Q: Can steel coils be coated with color-changing materials?

- Yes, steel coils can be coated with color-changing materials. These materials, commonly known as thermochromic or photochromic coatings, can change color based on temperature or exposure to light, respectively. The application of such coatings on steel coils can provide an aesthetically pleasing and dynamic visual effect, making them suitable for various applications like automotive, architectural, and consumer products.

- Q: How are steel coils used in the production of transportation systems?

- Steel coils are used in the production of transportation systems for various applications such as the manufacturing of automobile parts, railway tracks, and shipping containers. The coils are typically used to create strong and durable components that can withstand the harsh conditions and heavy loads associated with transportation.

- Q: What are the different methods of cutting steel coils into sheets?

- There are several methods used to cut steel coils into sheets, including shearing, slitting, and laser cutting. Shearing involves using a straight blade to cut through the coil, while slitting uses circular blades to make multiple cuts simultaneously. Laser cutting, on the other hand, utilizes a high-powered laser beam to melt through the steel. Each method has its own advantages and is chosen based on factors such as the desired precision, speed, and cost-effectiveness.

- Q: What's the length of a coil of cold rolled steel? Is there a standard?

- Generally, according to the volume measurement, each roll weighs 3~15 tons.

- Q: What could the impurities in steel wool be?And why are they there?Thanks for your help :)

- Impurities in steel wool would be of the elemental type. I'm sure steel wool is a mixture of different low grade not good for much of anything else materials. There may be excessive impurities such as lead, cobalt, boron, aluminum etc... in the steel wool. There may also be solvent residue on the wool i.e cleaner, lubricant etc.. I'm sure every batch is different - I know the iron level is high thats what makes them rust quickly.

- Q: Do you know of any movies that featured the steel drum?

- You okorder /.. If I can find any clips, I'll add them, but I'm sure that many movies in the proper settings (Trinidad, etc.) would have such music and/or show a group or at least a single performer. For example, Cool Running could be a possibility.

Send your message to us

Pre-Painted Galvanized Steel Coil/Construction Purposes/Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords