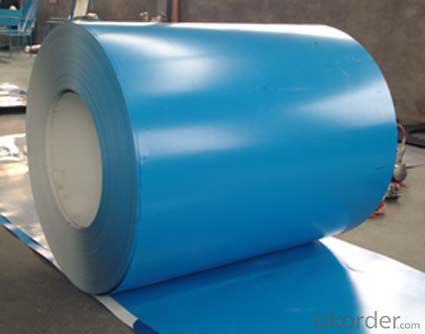

Pre-Painted Steel Coil Blue Color Prime Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvalume Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvalume Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvalume Steel Coil Images

4.Pre-Painted Galvalume Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvalume Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the production of steel fasteners?

- Steel coils are used in the production of steel fasteners as they serve as the raw material for manufacturing various types of fasteners such as screws, bolts, nuts, and washers. The steel coils are unwound and then processed through machinery that cuts, shapes, and forms them into the desired fastener shape. This allows for efficient and precise production of steel fasteners, ensuring their strength, durability, and compatibility with various applications.

- Q: Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q: What are the factors affecting the lifespan of steel coils?

- The lifespan of steel coils can be influenced by various factors. To begin with, the quality of the steel utilized in the coil manufacturing process plays a significant role. Steel of high quality, possessing appropriate composition and metallurgical properties, tends to have a longer lifespan in comparison to lower-quality steel. Moreover, the environment in which the steel coils are stored and utilized also impacts their longevity. Exposure to extreme temperatures, humidity, and corrosive substances can result in the degradation and corrosion of the coils, ultimately reducing their lifespan. To prolong the lifespan of the coils, it is crucial to maintain proper storage conditions, including controlled temperature and humidity levels. Additionally, the handling and transportation of steel coils can have an effect on their lifespan. Mishandling, such as dropping or improper loading and unloading, can lead to physical damage, causing premature failure of the coils. Similarly, rough transportation conditions characterized by excessive vibration or impact can contribute to coil deterioration and a reduction in their lifespan. Furthermore, the maintenance and care of the steel coils also play a role in determining their lifespan. Regular inspections, cleaning, and maintenance practices aid in the identification and resolution of potential issues before they escalate into major problems. Moreover, applying protective coatings or treatments to the coils can prevent corrosion and extend their lifespan. In summary, the lifespan of steel coils is influenced by a combination of factors, including steel quality, storage conditions, handling and transportation, and maintenance practices. It is essential to consider these factors and implement appropriate measures to ensure the longevity of the coils.

- Q: so i've started learning to play guitar in the past few weeks, and i'm using my sister's old guitar which isn't in very good condition, so i'm planning on buying a new one, but which would be better to buy, nylon string or steel string?

- It rather relies upon on what type of music you're enjoying, nylon string guitars have a mellow, softer tone than steel strings, the feel of the nylon strings (a minimum of to me) are reliable, in my opinion, i might ought to declare nylon is extra suitable, large for finger choosing and a effective tone. once you're searching for a guitar, you are able to flow out to a close-by guitar save, and attempt the two out for your self, in straight forward terms then will you comprehend for specific.

- Q: How do steel coils contribute to the agricultural machinery industry?

- Due to their versatile and durable nature, steel coils play an essential role in the agricultural machinery industry. They are used in various applications and contribute significantly to improving the efficiency and productivity of agricultural machinery. Manufacturing equipment frames and structures is one primary way steel coils contribute to the agricultural machinery industry. These frames provide the necessary strength and stability to withstand the demanding conditions of agricultural operations. Whether it's tractors, harvesters, or tillers, steel coils are utilized to create robust and rigid frames capable of handling heavy loads, vibrations, and impacts. Moreover, steel coils are vital in fabricating components like plow blades, cultivator tines, and seed drills. These components are crucial for soil preparation, seed planting, and crop maintenance. Steel coils provide the necessary strength and resistance to wear and tear, ensuring these components can endure the rigors of agricultural operations and have a prolonged lifespan. Additionally, steel coils are used in manufacturing hydraulic systems and other moving parts in agricultural machinery. These systems are responsible for powering and controlling various functions such as lifting, lowering, and steering. Steel coils provide the necessary strength and flexibility for these systems to function optimally, ensuring smooth and efficient operation of agricultural machinery. Furthermore, the use of steel coils in the construction of agricultural machinery enhances equipment safety and longevity. Steel is renowned for its excellent resistance to corrosion, rust, and extreme weather conditions. By incorporating steel coils in the manufacturing process, equipment remains durable and reliable even in harsh environments, ultimately reducing maintenance costs and improving the overall lifespan of the machinery. In conclusion, the agricultural machinery industry heavily relies on steel coils. Their versatility, strength, and durability are indispensable for manufacturing equipment frames, components, hydraulic systems, and other moving parts. By utilizing steel coils, the agricultural machinery industry can produce robust and efficient equipment capable of withstanding demanding agricultural operations, improving productivity, enhancing safety, and extending the lifespan of the machinery.

- Q: How are steel coils processed into finished products?

- Steel coils are processed into finished products through a series of steps that typically include uncoiling, leveling, cutting, and shaping. After uncoiling, the steel coils are passed through a leveling machine to remove any unevenness. Then, they are cut into specific sizes and shapes using different cutting techniques such as shearing or slitting. Finally, the cut steel pieces are shaped through various processes like bending, welding, and machining to produce the desired finished products.

- Q: What are the different certifications required for steel coil manufacturers?

- Steel coil manufacturers may be required to obtain various certifications in order to operate in the industry, ensuring that they meet specific quality and safety standards. One widely recognized certification is the ISO 9001, an international standard for quality management systems. This certification demonstrates the manufacturer's commitment to consistently meeting customer and regulatory requirements through the implementation of effective processes and procedures. Another crucial certification is the ISO 14001, which focuses on environmental management systems. By obtaining this certification, manufacturers prove their dedication to implementing sustainable practices and minimizing their environmental impact. In terms of safety, manufacturers may need certifications like the OHSAS 18001 or ISO 45001, which are standards for occupational health and safety management systems. These certifications guarantee that the manufacturer has established proper processes and controls to ensure the well-being of their employees and stakeholders. Additionally, manufacturers may require industry-specific certifications such as the American Institute of Steel Construction (AISC) certification, which is specific to structural steel fabrication and erection. This certification ensures that the manufacturer adheres to the best practices in the industry. Furthermore, manufacturers may need certifications related to specific product standards, such as the American Society for Testing and Materials (ASTM) certification. This certification guarantees that the manufacturer's products meet specific quality and performance requirements. Acquiring these certifications is crucial for steel coil manufacturers as they provide customers with confidence in the quality, environmental responsibility, and adherence to industry standards of their products.

- Q: What are the different types of steel coil edges?

- Various steel coil edges exist, each possessing unique characteristics and applications. 1. Mill Edge: The most prevalent type, it is obtained by cutting the coil at the mill without undergoing any further processing or treatment. Mill edge coils have a natural, slightly rounded edge, making them suitable for a wide array of applications. 2. Slit Edge: Slit edge coils are created by cutting the coil across its width using a slitting machine. This results in a straight and smooth edge, making them ideal for precise measurements needed in automotive parts or electrical components. 3. Deburred Edge: Deburred edge coils have undergone an additional process to eliminate any burrs or sharp edges that may exist after slitting. This ensures safer handling and reduces the risk of damage during fabrication or installation. Deburred edge coils are commonly used in the construction industry, particularly for structural steel components. 4. Rounded Edge: As the name implies, rounded edge coils possess a curved edge profile achieved through a specific rolling process. This creates a smooth and curved edge, making them often utilized in applications prioritizing safety, such as the manufacturing of household appliances or kitchen equipment. 5. Sheared Edge: Sheared edge coils are produced by cutting the coil using shearing blades, resulting in a straight edge with a slight burr. While sheared edge coils may have a rougher finish compared to other edge types, they are still frequently used in applications that do not require a high level of precision, like general fabrication or shelving. In summary, the choice of steel coil edge depends on specific application requirements, including factors such as measurement precision, safety considerations, and aesthetic preferences.

- Q: I've heard different things bout them, though I do not know this. Oh, and if you know where you can buy some raw or get custom made stuff out of black steel please let me know it would be greatly appreciated. Oh and my friend told me there is a black steel that can be sharpened and silver will be underneath, is this also true? Thank you very much for answering ^^

- Black steel is steel with a surface layer of dark coloured iron oxides used for low pressure hot water heating pipes. Black iron is iron without any finish on it, which is really gray-black in color. they may be the same as many people often confuse iron and steel. Since the steel is simply steel with a covering, it could describe any steel including your silver steel.

- Q: The steel is orangish in colour and is mostly made of copper

- Steel is an alloy of iron and carbon and optionally one or more of numerous other materials. Copper is normally not used, except sometimes in small percentages. Steel is never yellow or orange in color. Reactivity of steel depends on the materials it is alloyed with. Chromium and nickel with steel make stainless steel, which is much less prone to reactive than iron. .

Send your message to us

Pre-Painted Steel Coil Blue Color Prime Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords