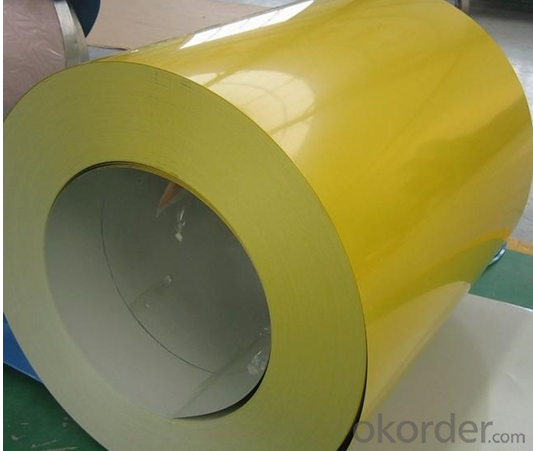

Pre Painted Galvanized Steel Sheet or Coil in Yellow

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: All the appliances in my kitchen are stainless steel, and I hate how they look becuase every time I wash them they are full of streaks. Is there a good cleaner made for stainless steel that won't leave streaks?

- Stainless Steel Appliance Cleaning Stainless steel kitchen appliances look best when they're clean and shiny. To clean tough stains and cooking grease, and give them a dazzling shine, try the same detergent you would use when washing the dishes. One formulated to cut grease works especially well.This also works well for general kitchen cleaning.Waterless hand soap also works great as a polish, simply rub on, and polish - no rinsing.=)

- Q: I have a belly button piercing and the metal is stainless steel.. I was wondering does it develop rust whenever you go shower and clean it? Can I still swim in the summer with it or do I have to take it out? What happens if I swim in the pool with it?

- No it won't rust. Just make sure to get the pool water out of the piercing when done at the pool. Just to avoid drying out the skin too much.

- Q: Are steel coils resistant to rust and corrosion?

- Yes, steel coils are typically resistant to rust and corrosion due to their protective coating or treatment that prevents the steel from coming into direct contact with moisture or oxygen.

- Q: How are steel coils used in the manufacturing of structural components?

- Steel coils are used in the manufacturing of structural components by being processed and formed into various shapes such as beams, columns, and plates. These coils are first uncoiled and then cut into desired lengths before being shaped and welded together to create strong and durable structural components used in buildings, bridges, and other infrastructure projects.

- Q: What are the different types of steel surface treatments for coils?

- There are several types of steel surface treatments for coils, including hot-dip galvanizing, electro-galvanizing, galvannealing, and organic coating. Hot-dip galvanizing involves immersing the steel coil in a bath of molten zinc to create a protective layer. Electro-galvanizing applies a thin layer of zinc to the surface using an electrical current. Galvannealing is a process that combines galvanizing and annealing to create a zinc-iron alloy layer. Organic coating involves applying a protective layer of paint or other organic material to the steel surface.

- Q: How are steel coils used in the production of agricultural irrigation systems?

- Steel coils are used in the production of agricultural irrigation systems as they are often used to manufacture pipes and tubing. These coils are shaped and cut into specific lengths to create the necessary components for the irrigation systems. The steel material provides durability and strength to withstand the pressures and demands of distributing water in agricultural fields efficiently.

- Q: I'm a Hobbyist and want to Build my own axial-flow jet engine,can I use steel as the Turbine blades instead of Titanium which I can't get easily?? What about the other parts I can use for...?!

- You can use steel but alloyed with a big percent of Mn and Cr. Titanium is very good but unfortunately it is expensive. On engines and Turbine blades it is indicate to use High Alloy metals that are resistant to fluage.

- Q: How are steel coils inspected for yield strength using tensile testing?

- Tensile testing is the method used to inspect the yield strength of steel coils. This involves subjecting a sample of the coil to controlled tension until it reaches its breaking point. Through this test, various mechanical properties of the steel, including yield strength, can be determined. To conduct the tensile testing for yield strength inspection, a small strip of the coil is cut and prepared. The strip is then placed in a machine specifically designed for tensile testing. This machine consists of two grips that securely hold the strip at opposite ends. Subsequently, the machine applies a steadily increasing force to the strip, causing it to elongate until it eventually breaks. Throughout the test, the machine measures the force applied and the elongation of the strip. The yield strength is determined by identifying the point on the stress-strain curve where the material begins to undergo plastic deformation, meaning it exhibits permanent deformation without any increase in load. Typically, the yield strength is reported as the stress required to cause a specific amount of plastic deformation, such as 0.2% or 0.5%. This value represents the maximum stress that the steel can endure without experiencing permanent deformation. By performing tensile testing on a sample of the steel coil, it becomes possible to ascertain its yield strength. This information is vital in ensuring the quality and dependability of the steel coil, as it indicates the maximum stress it can tolerate before permanent deformation occurs. Furthermore, this testing method allows for the comprehensive evaluation of other mechanical properties, including ultimate tensile strength, elongation, and modulus of elasticity, thus providing a thorough understanding of the steel's performance characteristics.

- Q: Edward Humphrey wants to know... Can I use steel roofing on an older house?

- steel roofing is a very logical option when considering replacing a residential roof. Keep in mind that in addition to the cost of the actual metal roofing panel, most likely, in order to qualify for the warranties associated with these products, you must also use their accessories and adhere strictly to their installation instructions. If you have a very cut up house, lots of dormers and valleys, etc, the costs to waterproof these areas before installing can get to be costly, but as far as a straight forward reroof over existing substrate, costs are very competitive. As much as I see a lot recommend going over existing shingles, I prefer to strip the existing shingles, and check the sheathing, before waterproofing and roof installation.

- Q: What are the different methods of steel coil surface cleaning?

- There are several different methods of steel coil surface cleaning, including mechanical cleaning, chemical cleaning, and high-pressure water cleaning. Mechanical cleaning involves using abrasive materials or brushes to remove dirt, rust, and other contaminants from the surface of the steel coil. Chemical cleaning involves using chemicals or solvents to dissolve or remove contaminants from the surface. High-pressure water cleaning uses water jets at high pressures to remove dirt and debris from the surface. Each method has its own advantages and is chosen based on the specific requirements and condition of the steel coil.

Send your message to us

Pre Painted Galvanized Steel Sheet or Coil in Yellow

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords