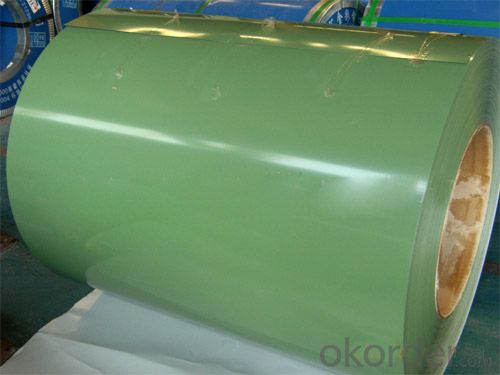

Pre-Painted Galvanized Steel Coil in High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

- Q: i have a sword and some knives that have this grade steel. so is it a high grade or low grade? and how can i tell the differance between a high grade and a low grade?

- For throwing knives, 440 isn’t necessarily a bad choice. Does it list whether it is 440c or 440b? That matters somewhat. The advantages of 440 Stainless is that it’s relatively hard (for a stainless), it resists rust significantly, and it’s not so hard that it would shatter or break. On the down side 440 is notorious for not taking or holding an edge, but for a throwing knife, that’s probably not much of an issue. If you’re looking for something to train with, you’re fine here. It’s plenty of steel enough to stick in wood or other targets. Odds are it won't bend if you slam it into some wood. If it lands on concrete, eh, it's going to scratch and all that jazz, and it might hurt the tip if it hits first, but as has been said, you can use a file or grinder to get the tip back.

- Q: What are the common standards and specifications for steel coils?

- In the industry, there are various widely recognized and utilized standards and specifications for steel coils. Some notable ones include: 1. ASTM A36/A36M: This specification is concerned with carbon structural steel shapes, plates, and bars of structural quality. It is intended for use in constructions that involve riveting, bolting, or welding. 2. ASTM A572/A572M: This specification focuses on high-strength low-alloy columbium-vanadium structural steel shapes, plates, sheet piling, and bars. It is applicable for constructions involving bolting, riveting, or welding. 3. ASTM A653/A653M: This specification pertains to steel sheet that is zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) through the hot-dip process. 4. ASTM A1011/A1011M: This specification covers various types of steel sheet and strip in coils, such as hot-rolled, carbon, structural, high-strength low-alloy, high-strength low-alloy with improved formability, and ultra-high strength. 5. JIS G3302: This Japanese Industrial Standard specifies the requirements for hot-dip zinc-coated steel sheet, also known as galvanized steel sheet, and strip. 6. EN 10111: This European standard outlines the requirements for continuously hot-rolled low carbon steel sheet and strip that are suitable for cold forming. 7. ISO 3575: This International Organization for Standardization standard lays down the requirements for hot-dip zinc-coated and zinc-iron alloy-coated steel sheet and strip. These are just a few instances of the prevalent standards and specifications employed for steel coils. It is crucial to note that different industries and applications may have specific demands, thus consulting the relevant standards and specifications for the particular application is always advisable.

- Q: What are the typical coil width options?

- The typical coil width options vary depending on the industry and application, but common options range from 1 inch to 72 inches or more.

- Q: I have two theories, which one's correct?My book says that steel is made up of 98% iron and 2% carbon.98% of iron's molar mass (55.85 g/mol) is 54.733.2% of carbon's molar mass (12.01 g/mol) is .2402.If you add them up that gives you that steel has a molar mass of 54.97 g/mol.However, steel's chemical formula is Fe(3)CThat would make it's molar mass 179.56 g/mol.( Because 3(55.85) + 12.01 = 179.56 )Which one is correct?

- Molar Mass Steel

- Q: What are the different methods of coil leveling?

- There are several methods of coil leveling that are commonly used in various industries. These methods include: 1. Roller leveling: This method involves passing the coil through a series of rollers that apply pressure and gradually flatten the coil. The rollers can be adjusted to apply varying levels of pressure, allowing for precise control over the leveling process. 2. Stretch leveling: In this method, the coil is subjected to tension forces that elongate the material and remove the internal stresses. The coil is passed through a series of rollers while being stretched, which results in a more uniform and flat surface. 3. Temper leveling: This method involves heating the coil to a specific temperature and then cooling it rapidly. The rapid cooling process helps to equalize the stresses within the coil and improve its flatness. Temper leveling is often used for high-strength steels. 4. Roller leveling with leveling rolls: This method uses additional leveling rolls that are positioned above and below the main leveling rollers. The leveling rolls apply pressure to specific areas of the coil to correct any unevenness or distortions. 5. Tension leveling: This method involves applying tension to the coil while it is being processed. The tension helps to straighten and flatten the material, resulting in a more even and flat surface. 6. Precision leveling: This method is used for high-precision applications where extremely flat and uniform coils are required. Precision leveling involves a combination of roller leveling, stretch leveling, and other corrective measures to achieve the desired level of flatness. Each of these methods has its own advantages and limitations, and the choice of method depends on factors such as the type of material being leveled, the required flatness tolerance, and the intended application of the coil.

- Q: What are the common coil diameters available for steel coils?

- The common coil diameters available for steel coils typically range from 24 inches to 72 inches.

- Q: Is boron steel or carbon steel a harder metal? Which one is more flexible?

- The only thing that affects the hardness of steel is the carbon content. But there are many elements that can make it easier for a steel to achieve its maximum hardness. And Boron is an extremely effective element that increases the hardenability of steel. Adding as little as 0.002% Boron can have a big impact upon quenching of a steel. Boron is usually added when you need the hardness of a heat treated steel part to extend deep below the surface. For example, lets say you had a two identical plain carbon steel parts, but one had boron and the other didnt, and you wanted to heat treat them both After quenching, the surface should be the same on both, and lets say its 55 Rockwell C. In the plain carbon one, the hardness might drop down to 50 at 2mm under the surface, but the boron treated one might not drop to 50 until 4mm under the surface. Now, these numbers were completely made up, and it would depend on the specifics as to what the difference might be.

- Q: So I want to get my 3+ wood shafted with a dynamic gold shaft because i need a stiffer shaft but dont want to spend much on it.I've never swung a steel shafted wood, but I hear that it is more consistent that graphite....Plus, since the cost of steel is only $15 compared to the $65 graphite, not to mention installation charges.So yeah...... How good is steel for fairway woods?BTW, my swing speed is about 95 but i can amp it up to 110 (with control, that is)

- i take advantage of a three timber off the tee while a motive force could bypass in the process the fairway on a dogleg, or while the fairway gets narrower the further you hit it. Use it to get as close to to a par 5 in 2 as i will, or perhaps even attain a par 5 in 2. Use it to make up floor in case you permit out a rigidity, every time the photos demands me to hit it between 220 and 235 it quite is approximately how some distance I hit my 3 timber. I additionally carry a 5 timber which I hit approximately 2 hundred to 215 and extremely severe so it lands comfortable. i do no longer carry any hybrids regardless of the undeniable fact that as I nevertheless like to hit long irons.

- Q: I'm in the process of buying a new car, and wondering if there are more benefits from Aluminum tire rims over Steel. Aluminum wheels cost more, but you'd think that steel would last longer. Are Aluminum wheels just for looks?

- aluminum is lighter , alot of performance cars use them to trim unsprung weight from the wheels ... steel wheels are cheaper but u have to put hub caps on them ... eeeeeuuuuueeewww!!!!!

- Q: Are steel coils used in agricultural equipment manufacturing?

- Yes, steel coils are commonly used in agricultural equipment manufacturing. Steel coils are used to create various components such as frames, brackets, and supports, which are essential for the construction and durability of agricultural equipment. The strength and versatility of steel make it a preferred material choice for manufacturing agricultural machinery.

Send your message to us

Pre-Painted Galvanized Steel Coil in High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords