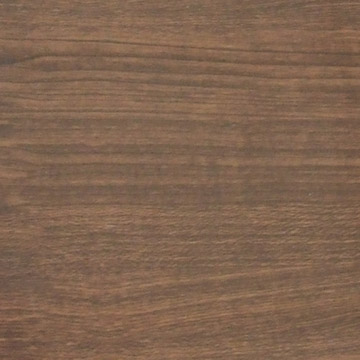

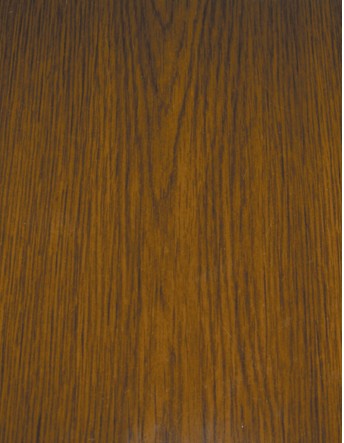

Pre-painted Galvanized Steel Coil-EN10169-WOODEN6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- Musical style speaks volumes when it comes to this issue. Those who want high volume will be unhappy with unamplified nylon string guitars. From my perspective, the basic difference between steel and nylon is this: steel strings ring and nylon strings resonate. The volume produced by steel is generally much greater than nylon but, to my way of thinking, the sound resonance produced by the wood of your guitar is largely masked by steel strings. If you have a decently made guitar (generally, around a thousand dollars and up), the sound interplay between the wood and the strings in a nylon guitar is magical across the entire frequency range. With a steel string guitar, the sound produced by the vibrating string overpowers the wood resonance at all but low frequencies. Personally, I'll take a nylon string guitar any day for the sensitivity gained from the interplay between wood and vibrating string.

- Q: I just bought a used Taurus 85 stainless 38 spl revolver, it's about 25 years old but looks like new. This is my first stainless steel gun. I'm wondering if there's any special things I need to be aware of or cleaning methods? I'm also wondering if stainless steel could rust? in theory stainless means it cannot get stained or rusty. I have a chrome bore AK, cleaning is always super easy, wondering of cleaning a SS revolver would be the same.

- Yes, stainless steel will rust. It is not rust proof, it is rust resistant. You still should oil your gun after you shoot it.

- Q: I got my dog those nice looking stainless steel water and food bowls (looks great next to my kitchen appliances...haha). The thing is my dog will drink from the toilet or a plastic bowl but not out of his bowl...I was wondering if those stainless steel bowls change the taste of food and water?

- My cats will eat their food from a stainless steel bowl but only drink their water from a plastic or ceramic bowl. This is a little far fetched, but maybe they get scared when they see their reflection in it. You know like when you look into a stainless steel toaster, you're face looks all distorted -- maybe the water in addition to the stainless steel is scary to them. The stainless steel pet dishes I have claim to be non-microbial (bacteria free) or something like that. Maybe whatever they use for this is affecting the taste of the water. The food, on the other hand, since it already has a flavor (water has no flavor), maybe it's not so noticeable.

- Q: How are steel coils used in the manufacturing of storage systems?

- Steel coils are an essential component in the manufacturing of storage systems due to their durability, strength, and versatility. These coils are typically made from high-quality steel and are created by rolling the steel into a coil shape. In the manufacturing process of storage systems, steel coils serve various purposes. One of the primary uses of these coils is for the construction of shelves, racks, and frames. These components provide the structural support necessary to hold and organize items within the storage system. The strength of the steel coils ensures that the storage system can withstand heavy loads and remain stable over time. Additionally, steel coils are also used in the production of storage system accessories such as brackets, hooks, and dividers. These accessories provide additional functionality and customization options for the storage system, allowing users to optimize their storage space based on their specific needs. Moreover, steel coils are often used as the material for doors and panels in storage systems. The coils are molded and shaped to create sturdy and secure doors that provide easy access to the stored items while maintaining the overall integrity of the system. These doors can be designed with various locking mechanisms to enhance security and prevent unauthorized access. Furthermore, steel coils are crucial in the manufacturing of mobile storage systems. These systems, such as mobile shelving units or compactors, are designed to maximize storage capacity in limited space. The flexibility and versatility of steel coils allow for the creation of movable components that can be easily adjusted and reconfigured to accommodate changing storage requirements. Overall, steel coils play a vital role in the manufacturing of storage systems by providing the necessary strength, durability, and versatility required for these structures. Whether it is for shelves, accessories, doors, or mobile systems, steel coils ensure that storage systems are reliable, secure, and efficient in organizing and storing various items.

- Q: What are steel coils?

- Steel coils are long, flat sheets of steel that have been wound into a coil shape. They are used in various industries for manufacturing purposes, such as in the automotive, construction, and appliance industries. Steel coils are typically made from carbon steel and are commonly used for applications that require strength and durability.

- Q: looking to buy a sashimi knife. what is the difference between white steel (1and2) and blue steel (1and2) in terms on characteristics. what gets sharper? what holds edge longer? basically any info on the pros and cons of each steel would be SO GREATLY APPRECIATED! thanks in advance to all who answer. i'm leaning towards white-2 steel for my first sashimi knife, started training on the sushi bar and need a new tool!

- Actually okorder /

- Q: Are steel coils used in construction?

- Yes, steel coils are commonly used in construction. They are widely utilized in various applications such as structural frameworks, roofing, flooring, and cladding systems. Steel coils provide strength, durability, and flexibility, making them an essential material for construction projects.

- Q: I'm a Hobbyist and want to Build my own axial-flow jet engine,can I use steel as the Turbine blades instead of Titanium which I can't get easily?? What about the other parts I can use for...?!

- Yes you can use steel but you will want to use super alloys like hastaloy and inconel. These withstand the heat in the combustion areas. These are the actual materials used in these stages. If you only want your engine to have a service life of a few hours a conventional hot work steel like H-13 will probably be OK Blades are investment cast in foundries that carefully control the rate of cooling to create a very uniform grain structure

- Q: it seems like the hardness of Stainless steel, i saw 410c stainless stell, i saw 440c stainless steel, what does it means anyway?

- It is the alloy number given by the American Iron and Steel Institute, or AISI. This is the trade organization of the U.S. steel industry, one of the oldest such organizations. 440C is also known under the UNS system as S44004 440C is a high carbon, plain chromium stainless steel. Or more specifically: 18% Cr, ~1.1% C, ~1.0% Mo, Si, and Mn 440c is mostly used in cutlery, bearings, and valve parts; because it has the best strength and hardness after basic heat treatment of any stainless steel. Relatively poor properties in other areas make it less suitable for other types of items. for example 440c becomes very brittle in sub zero temperatures. 410 is similar to 440, but it is a cheaper milder steel with less chromium and carbon, so it is less brittle, more easily worked and machined, but lacks final strength and hardness. it is often used in cheap stainless fasteners and bushings.

- Q: How do steel coil manufacturers ensure fair pricing?

- Steel coil manufacturers ensure fair pricing by considering various factors such as production costs, market demand, and competition. They conduct cost analysis to determine the expenses involved in producing steel coils, including raw materials, energy, labor, and equipment. Manufacturers also evaluate market conditions and demand to set prices that align with prevailing rates. Additionally, they consider the pricing strategies of competitors to maintain a fair pricing structure that is competitive yet reflective of their costs and value proposition.

Send your message to us

Pre-painted Galvanized Steel Coil-EN10169-WOODEN6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords