Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvalume Steel Coil Description

With GI or GL as base metal, after pretreatment (degrease and chemical treatment) and

liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel.

Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance.

It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvalume Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvalume Steel Coil Images

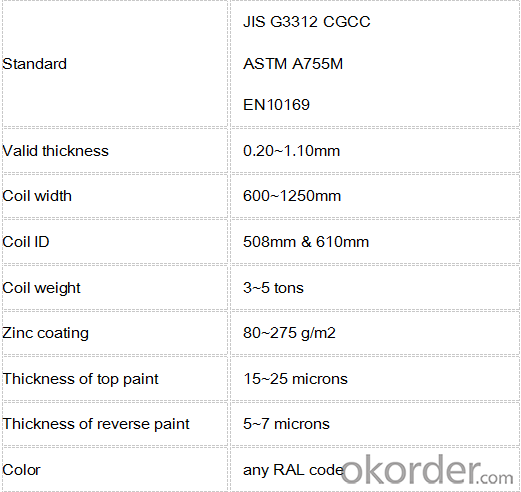

4.Specification of Pre-painted Galvalume Steel Coil

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvalume Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to fccts flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4:Please tell me the daily output and Pre-painted galvanized steel mill’s brand ?

Our daily output is 4000mt/day and our rolling mill from Germany’s SMS MEER

- Q: How are steel coils used in the manufacturing of household goods?

- Household goods rely on steel coils for their manufacturing, utilizing them in various ways. One notable application is in the creation of appliances like refrigerators, washing machines, and ovens. These coils are skillfully molded and formed into different parts and components, fortifying the final product with durability and robustness. Moreover, furniture manufacturing frequently incorporates steel coils, specifically in constructing metal frames for chairs, tables, and bed frames. The coils can be bent, welded, or molded to desired specifications, providing a solid and dependable foundation for these essential household items. Additionally, steel coils find utility in the production of kitchen utensils and cookware. These coils can be expertly stamped or pressed into diverse shapes, including pots, pans, and cutlery. Consequently, this process generates long-lasting and heat-resistant products that are indispensable for everyday cooking and food preparation. In essence, steel coils assume a critical role in the manufacturing of household goods, imparting strength, durability, and adaptability to a wide array of products.

- Q: What are the challenges in coil leveling for coated steel?

- Coil leveling for coated steel presents several challenges that need to be addressed in order to achieve high-quality, flat, and smooth coils. Firstly, one of the main challenges is the potential for coating damage during the leveling process. Coated steel coils are typically coated with materials such as zinc or paint, which can be easily scratched or marred if not handled properly. The leveling process involves passing the coil through a set of leveling rolls, which can potentially cause friction, abrasion, or other mechanical damage to the coating. Therefore, it is crucial to carefully control the speed, pressure, and alignment of the leveling rolls to minimize coating damage. Secondly, the thickness variation across the coil presents a significant challenge. Coated steel coils often have thickness variations due to inherent material properties or production processes. These variations can result in uneven leveling and can lead to coils with waviness or uneven flatness. Achieving uniform leveling across the entire coil surface is essential to ensure consistent quality and appearance of the final product. Another challenge in coil leveling for coated steel is the possibility of coil shape distortion. Coating processes can introduce stresses into the steel, which can cause the coil to warp or distort during the leveling process. This distortion can result in coils with uneven edges or inconsistent flatness. Proper control of the leveling process parameters, such as the number of leveling passes and the tension applied to the coil, is necessary to minimize shape distortion. Additionally, the coil leveling process can generate internal stresses in the steel itself, particularly in coated steels that have been cold-rolled or heat-treated. These internal stresses can cause coil spring-back, where the coil tries to return to its original shape after leveling. Spring-back can result in coils with unwanted curvature or uneven flatness. Effective strategies, such as stress relief annealing or using counteracting leveling techniques, are essential to minimize spring-back and achieve the desired flatness. Finally, the handling and storage of coated steel coils present challenges in maintaining the quality of the leveled coils. Coated steel coils are sensitive to environmental conditions such as humidity, temperature, and exposure to corrosive agents. Proper storage and handling practices are crucial to prevent coating damage, rust, or other forms of deterioration that can occur during transportation or storage. In summary, the challenges in coil leveling for coated steel include minimizing coating damage, addressing thickness variation, controlling shape distortion and spring-back, and ensuring proper handling and storage. Overcoming these challenges requires precise control of process parameters, the use of appropriate leveling techniques, and adherence to strict quality control measures throughout the entire process.

- Q: what are the properties that can strengthen the steel to withstand earhquake?

- okorder can give you helps.

- Q: What materials are used to make steel coils?

- Steel coils are primarily made from iron ore, coke, limestone, and scrap steel.

- Q: How are steel coils used in the manufacturing of industrial equipment?

- Steel coils are used in the manufacturing of industrial equipment as they serve as a primary raw material for fabricating various components such as frames, supports, and structural elements. These coils are often cut, shaped, and welded to create the desired parts and structures that provide strength, durability, and stability to the equipment. The steel coils ensure that the industrial equipment can withstand heavy loads, resist corrosion, and maintain structural integrity, making them vital in the manufacturing process.

- Q: What are the different methods of coil end welding for steel coils?

- There are several different methods of coil end welding for steel coils, which include resistance welding, laser welding, and electric arc welding.

- Q: What kind of insulation should be used in a steel building?

- Fiberglass batts or spray on foam both work well

- Q: I am a beginner and have a slow to average swing speed. Should i get graphite or steel shafts for my irons and does it make a difference?

- How about graphite in your 3,4,5 irons and lightweight steel in your scoring clubs. You can swingweight them all the same so you will have a consistent feel through out the entire set and you will get extra help getting the ball in the air with the long irons and extra stability in the scoring clubs. And you save money by not having to put graphite in the entire set. As a beginner the clubs you get now may not suit you as you progress and your swing evolves so keep this in mind when buying a set of irons.

- Q: How are steel coils used in the production of industrial shelving?

- Steel coils are used in the production of industrial shelving by being processed and shaped into various components such as shelves, frames, and brackets. These coils are cut, bent, and welded to create sturdy and durable structures that can support heavy loads in industrial settings. The strength and versatility of steel make it an ideal material for manufacturing industrial shelving, ensuring durability and longevity of the shelves.

- Q: What are the different methods of coil packaging for steel coils?

- There are several methods of coil packaging for steel coils, including stretch wrapping, strapping, banding, and shrink wrapping. Stretch wrapping involves wrapping a stretch film tightly around the coil to secure it. Strapping and banding use metal or plastic straps to hold the coils together. Shrink wrapping involves covering the coil with a plastic film that shrinks when heated, providing a tight and protective cover. These methods help to protect the coils during storage, transportation, and handling, ensuring they remain in good condition.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords