Pre-painted Galvanized/ Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

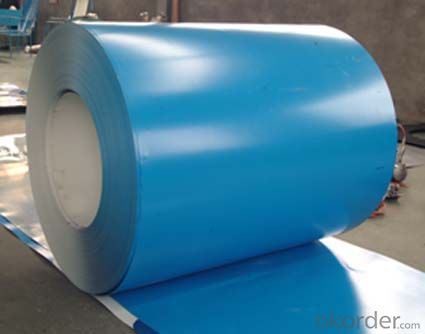

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size.

2. How long can we receive the product after purchase?

We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the different types of steel alloys used in coils?

- There are various types of steel alloys used in coils, including carbon steel, stainless steel, galvanized steel, and electrical steel.

- Q: How are steel coils protected from chemical damage?

- Steel coils are typically protected from chemical damage through various methods such as applying protective coatings or using barrier films. These protective measures act as a barrier between the steel surface and any potentially corrosive chemicals, preventing direct contact and minimizing the risk of chemical damage.

- Q: Why?Which one should i get? I am just starting to learn Guitar. Which one would be better for me? What is the difference? I already got the acoustic nylon but i might return it... if the steel is better.

- I okorder /

- Q: a picture of the atomic structure of carbon steel

- This is actually a quite complex question... The atomic arrangement in steels can be controlled over a pretty wide range of different structures. This is really the fundamental reason why steel is such a commonly used material. The different atomic structures produce different physical properties so metallurgists have developed many different processes to control the atomic structure to get the properties they want. One simple answer is that Fe is BCC, body centered cubic at room temperature at equilibrium conditions. When you heat Fe up, it transforms to FCC, face centered cubic. If you continue heating Fe, it goes back to BCC, then it melts. The addition of C makes these structures (and the transformation temperatures) different. Deviating from equilibrium conditions by, for example, cooling very quickly (quenching) creates different atomic structures (one of the most important is known as martensite). Depending on how much C is in the steel, you can also have two different atomic structures (two different phases) present in equilibirum, for example, pearlite which is a mix of alpha Fe (BCC) and iron carbide Fe3C (orthorombic crystal structure). So... you need to think a little more about exactly what you want a picture of. I hope this helps

- Q: They are showing on tv a special on how the new World Trade Center, building 1, is being built. Focusing on the steel and the guys fitting everything together.Where do builders go to buy all that steel framing? We do not build really tall buildings where I live so most of the steel is cut and welded on the job site. At World Trade Center 1, they seem to get the steel on trucks; already cut and welded.

- The steel is all custom fabricated in what are called structural steel fabrication shops. Each Building is designed by architects then the frame is designed by engineers to support whatever load is being applied to the building. After the engineering is done it goes out for a bid package where a fab shop estimates how much to charge for the fabrication of the steel and the erection of the steel. Once a company wins the bid, it then has to design how the steel will connect with one another and have it approved by an engineering firm to assure the connections are strong enough. Once all of that happens the fab shop orders raw steel beams and angle iron and steel plate at stock lengths. Beams are then cut into the right length and holes drilled in the proper places. The beam is then marked with a number that tells the erectors where it goes. The steel is then shipped out in batches to the construction site where it is unloaded and shook out into an organized place to grab them with a crane. They are then put together like a toy model, there are instructions that say what beam goes where and what size bolt to use. The welding you see being done is on really critical moments that need extra strength. That is about how it goes in a nutshell. It is a bit more complicated than that but it gives you an idea.

- Q: I saw this really pretty ring online and it was made of steel. Is this a good ring? If I were to wash my hands with it on, would it rust and turn my finger green?

- Steel rust is brown not green! Very much expected to be of one type of stainless steel, and you should have no problem.

- Q: Can steel coils be coated with impact-resistant materials?

- Yes, steel coils can be coated with impact-resistant materials. The coating process involves applying a layer of impact-resistant material onto the surface of the steel coils to enhance their durability and protection against impacts or damages. This coating can provide additional strength and resistance, making the coils suitable for various applications requiring impact resistance.

- Q: What are the main factors that affect the surface quality of steel coils?

- The main factors that affect the surface quality of steel coils include the quality of raw materials used, the manufacturing process employed, the level of cleanliness and maintenance of equipment, the presence of contaminants or impurities, the coating or finishing applied, and the handling and storage conditions.

- Q: I have samurai sword that is a replica of the kill bill sword. It says on the blade stainless steel, what can i use to shine and protect blade. It had and still does a wax.like coating on the blade sine i received it. Thx for ur help

- i like how you asked this in the Card Games section.

- Q: What are the common problems encountered with steel coils during production?

- Some common problems encountered with steel coils during production include surface defects such as scratches, rust, and scale formation, dimensional deviations, coil breaks or tears, edge defects, and coil slippage. Other issues may include coil handling and storage problems, coil winding or coiling defects, and quality control problems such as inconsistent chemical composition or mechanical properties.

Send your message to us

Pre-painted Galvanized/ Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords