Pre-Painted Galvanized/Aluzinc Steel Coil Workability Durability

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

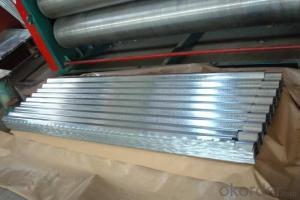

1. Pre-Painted Galvanized/Aluzinc Steel Coil Workability Durability

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Excellent heat resistance performance

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils tested for mechanical properties?

- Steel coils are tested for mechanical properties through various methods, including tensile testing, hardness testing, and impact testing. Tensile testing involves subjecting a small sample of the steel coil to a controlled force, measuring the amount of force required to deform or break the material. Hardness testing determines the resistance of the steel to indentation or scratching, providing insights into its strength and durability. Impact testing assesses the ability of the steel to withstand sudden loads or shocks by striking a sample with a pendulum and measuring the energy absorbed during fracture. These tests help evaluate the quality and suitability of steel coils for specific applications.

- Q: How are steel coils used in the manufacturing of engine mounts?

- Steel coils are commonly used in the manufacturing of engine mounts to provide durability, strength, and flexibility. These coils are typically designed to absorb and dampen vibrations, shocks, and movements generated by the engine during its operation. By integrating steel coils into the engine mount design, manufacturers can ensure better stability, improved performance, and reduced noise levels in vehicles.

- Q: I asked a question last week about stainless steel and got some great answers. I combed all over the internet to try to figure this one out but could not find anything. What resists bending better: chrome vanadium steel (i.e. a steel commonly used to make tools) or stainless steel 304. My guess would be the chrome vanadium alloy but thats just a guess. Which on resist's bending better and by how much (#'s please :-)). Also, if anyone knows if chrome vanadium steel is cheaper than stainless steel 304 that would be awesome? I can't find a price per pound on chrome vanadium steel anywhere! Please help. Thanks in advance-Josh

- All okorder /... it can only be hardened somewhat by cold working. Bending stiffness is not proportional to tensile strength.

- Q: What is the average price of a steel coil?

- The average price of a steel coil can vary depending on several factors such as the type of steel, the thickness and width of the coil, the market demand, and the location of purchase. Generally, the price can range from $500 to $1500 per metric ton. However, it is important to note that prices are subject to fluctuations in the steel market, which can be influenced by global economic conditions, trade policies, and supply-demand dynamics. Therefore, it is advisable to consult with steel suppliers or monitor market trends to get the most accurate and up-to-date pricing information.

- Q: What are the common uses of stainless steel coils?

- Stainless steel coils have various common uses in different industries. Some of the most common applications include manufacturing of kitchen appliances, automotive parts, construction materials, and medical equipment. Additionally, they are used in the production of pipes, tubes, and wire products, as well as in the food and beverage industry for processing and storage equipment.

- Q: Several reading methods of steel tape measure

- Precise steel tape factory and after a period of time must go through the verification and indicate the verification of temperature, tension and feet. Feet marked on the length of its nominal length, and the difference between the actual length is called length correction delta l ruler by different tension will make feet long. To avoid this change requires the use of steel tape according to the scale mark force of steel tape. At different temperature the foot will change with the temperature so it is necessary to use t as variable function to represent the feet long, this is the ruler length equation, its general form:

- Q: Edward Humphrey wants to know... Can I use steel roofing on an older house?

- In the town that I live it is getting really popular.The good thing is the old roof doesn't need torn off you just put 2in boards the width or the steel on the old roof and then screw the steel roof panels to it.

- Q: How are steel coils used in the manufacturing of automotive doors?

- Steel coils are used in the manufacturing of automotive doors by being shaped and cut into the desired size and shape for the door panels. These coils are then formed into the appropriate curvature and attached to the door frame, providing strength, rigidity, and durability to the door structure.

- Q: What is the role of steel coils in the production of appliances?

- The role of steel coils in the production of appliances is to provide a strong and durable material for various components, such as the outer body, internal structures, and key parts. Steel coils are used to manufacture appliance parts like panels, frames, and brackets, ensuring stability, strength, and longevity. The versatility and strength of steel make it an ideal choice for appliances, as it can withstand heavy loads and provide the necessary support and protection.

- Q: i want to buy an exhaust but whats the difference between satinless steel and titanium exhaust?

- Stainless steel is more corrosion resistant than steel and titanium is more corrosion resitant and lighter. However, titanium is more prone to picking up (scratches caused by normal tools creating scratches and leading to stress fractures). The Lockheed Blackbird had to have tools treated lithium grease (i could be wrong) to prevent this. I'd stick with stainless steel as i think any titanium exhaust you can buy will be a titanium composite due to its cost

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil Workability Durability

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords