Pre-Painted Galvanized/Aluzinc Steel Coil --Good Visual Effect

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil --Good Visual Effect

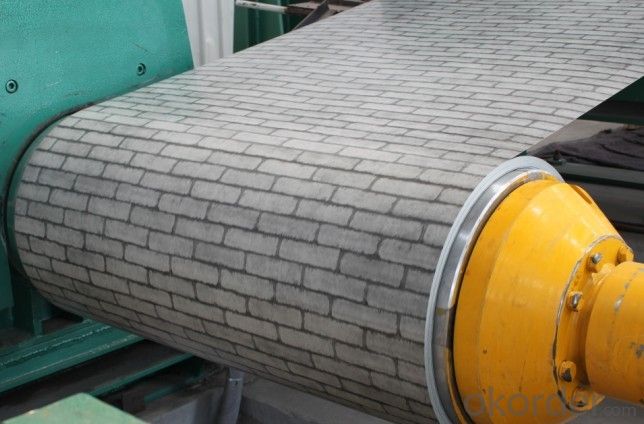

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: All the appliances in my kitchen are stainless steel, and I hate how they look becuase every time I wash them they are full of streaks. Is there a good cleaner made for stainless steel that won't leave streaks?

- Stainless Steel Appliance Cleaning Stainless steel kitchen appliances look best when they're clean and shiny. To clean tough stains and cooking grease, and give them a dazzling shine, try the same detergent you would use when washing the dishes. One formulated to cut grease works especially well.This also works well for general kitchen cleaning.Waterless hand soap also works great as a polish, simply rub on, and polish - no rinsing.=)

- Q: - I'm considering doing my physics coursework on the uses of Mild Steel in skyscrapers and construction, would this be right? Some sources tell me mild steel is too weak, others say it is fine

- Mild steel doesn't really mean anything, technically. In today's world all steel is mild steel unless it's high carbon or alloy, which are mostly tool steels. You'll need to study steel much deeper than that to accomplish any real physics work relating to steel.

- Q: where to buy Transformer steel?Used in transformers and electric motors.

- Electrical Steel Suppliers

- Q: i am working in a firm that deals with steels.. so it is necessary for me to understand the chemistry of the steels from their names so that i need not memorize all the grades with their metallury.. where can i find information about this nomenclature ? please help

- For steels with a four number code like 1020, 4140 ect the first two digits are the alloying information. I think you need to memorise those. 10 steels are plain carbon steel with no alloying. 41 steels are chrome-molly. The third and forth digits are the carbon content. 1020 is 0.2% Carbon, 4140 is 0.4% carbon. I don't know if there is a system to stainless steels.

- Q: i mean cor ten steel( rusted)

- If the steel is true Cor Ten steel, it does not require waxing. Cor Ten is a steel designed to rust slowly over time ... then the rust acts as a natural barrier to prevent further rust. Check out the United States Steel building in downtown Pittsburgh, PA ... its nickname is The Rusty Nail.

- Q: I've been looking for lots of info on this steel. Cold Steel uses it now in their knives replacing the AUS-8 steel. I was hoping somebody had a knife with this steel who could give me some real first hand knowledge not just numbers. Thanks!

- Before I answer I must let you know that I have been a knife collector for 17 years, and have a great assortment of specialty and antique folding knives. As for your question, I wouldn't worry too much about it. The first answerer is very knowledgeable in this category. But in the real world, the steel chemistry of folding knives will never be as important as that of fixed blades or kitchen knives. The fact that manufacturures go through great lengths to advertise their superior steel is just for sales and bragging rights. When it comes down to it, a pocketknife might be useful, but it is never the best tool for the job. It is a compomised design from the beginning. If you need to cut a steak, a steak knife will do. A box cutter works best on cardboard. A razor works best for shaving, wire cutters best for cutting wire, an axe for chopping wood...I could go on. A pocket knife is never going to perform better than the real thing ( although I do prefer the can openers on Swiss army knives than real can openers). As for self defense, minus the concealability factor, a folding knife sucks compared to a fixed blade. But if you were to pull one out during an extreme circumstance, I doubt anyone is going to be effected by the Rockwell hardness.

- Q: Steel or stainless steel

- Steel often has impurities that can generate fumes, which cause a fever identical to smoke inhalation. You always need to be concerned about what you are breathing around hot metal.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- Does it say stainless steel on it?

- Q: How are steel coils used in the manufacturing of furniture?

- Steel coils are used in the manufacturing of furniture to provide structural support and stability. They are commonly used in the construction of sofa frames and mattress bases to ensure durability and longevity. The coils are typically formed into springs, which are then incorporated into the furniture to enhance comfort and provide a responsive seating or sleeping surface.

- Q: How are steel coils used in the production of shipping containers?

- Steel coils are used in the production of shipping containers as they serve as the primary material for constructing the container body. These coils are cut, shaped, and welded together to form the walls, roof, and floor of the container, providing strength, durability, and protection for the goods being transported.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil --Good Visual Effect

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords