Pre-painted Galvanized/Aluzinc Steel Coil/PPGI Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications;

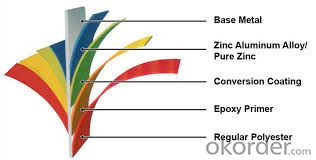

1. Aluzinc coating mass: 30g-275g/sqm

2. Coil weight: 4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

8. Supply Ability: 30000MT/month

9. Application: The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

10. Delivery time: Within 30 days after the receipt of L/C or Signed the contract or according to customer's requirement.

Special design available according to requirement; Anti-corrosion And high-temperature resistant with black painting; All the production process Are made under the ISO9001: 2000 strictly

Second Glance of Photo

Galvanzied steel coil( GI, CRC)

Color coated steel coil(PPGI)

Package: Sea worthy Export Packing Standard export and seaworthy packing. (waterproof paper and metal sheet protection with fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil)

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

- Q: Which steels were origianally designed to be used to cut and shape metals and other materials?- alloy steel- high carbon steel- carbide steel- tool steelthanks

- Steels okorder

- Q: What are the different methods of tension leveling for steel coils?

- There are various techniques available for tension leveling steel coils, each with its own benefits and applications. 1. Roller leveling: By passing the steel coil through a series of rollers under high tension, strategically positioned to exert pressure on the coil, this method effectively stretches and elongates the coil. It is commonly used for thinner gauge coils and effectively eliminates defects such as coil set, crossbow, and edge wave. 2. Stretch leveling: This technique involves subjecting the steel coil to a combination of tension and elongation. The coil is held by clamps at both ends and then stretched using hydraulic or mechanical devices. This process helps remove residual stresses, flatten the coil, and enhance shape control. Stretch leveling is particularly suitable for thicker gauge coils, effectively eliminating wavy edges and center buckle. 3. Temper rolling: By passing the steel coil through a series of temper rolls that apply pressure on the surface, this method is primarily used to improve the surface finish and enhance the mechanical properties of the steel. It also helps reduce coil set and improve flatness. 4. Skin pass rolling: After the primary leveling process, the steel coil is passed through a series of rolls that apply light pressure on the surface. This technique is typically performed to further improve surface finish, enhance flatness, and reduce surface defects such as scratches or marks. 5. Stretcher leveling: This technique involves clamping the steel coil at both ends and applying tension to stretch it. The stretched coil is then held in this position for a specific duration to allow for stress relief and shape correction. It is commonly used for thicker gauge coils and effectively removes defects like coil set, crossbow, and center buckle. Each tension leveling method offers distinct advantages and is suitable for different types of steel coils and specific requirements. The choice of method depends on factors such as coil thickness, desired flatness, surface finish, and the specific defects that need to be corrected.

- Q: What is the difference between steel coils and steel sheets?

- Steel coils and steel sheets, although both forms of steel, exhibit distinct differences. Steel coils, which are long rolls of steel wound into a coil shape, are typically produced at a steel mill and serve as raw materials for further processing or manufacturing. Various industries, including automotive, construction, and appliance manufacturing, commonly utilize steel coils in the production of items such as pipes, tubes, and automotive parts. Conversely, steel sheets are flat pieces of steel that are typically derived from steel coils. These sheets come in different sizes and thicknesses, making them versatile for various applications. Construction projects, such as roofing, siding, and structural components, often employ steel sheets. Additionally, they are utilized in manufacturing processes like stamping, forming, and fabricating diverse products. One primary distinction between steel coils and steel sheets lies in their shape and form. Steel coils adopt a cylindrical, rolled form, whereas steel sheets possess a flat, rectangular structure. This dissimilarity in shape renders steel coils more suitable for continuous production processes, while steel sheets find application in scenarios that demand flat surfaces. Another variation pertains to the handling and transportation of these steel forms. Due to their large size and weight, steel coils necessitate specialized equipment like coil cars or cranes for transport and storage. Conversely, steel sheets can be conveniently stacked, transported, and stored using conventional methods. Lastly, the processing requirements for steel coils and steel sheets differ. Steel coils often undergo additional processing steps, such as slitting, cutting, or coating, to meet specific customer requirements. Conversely, steel sheets may require minimal processing before being utilized in their intended applications. In summary, steel coils and steel sheets exhibit variances in shape, handling, transportation, and processing requirements. Steel coils, in their rolled, cylindrical form, are utilized for further processing, while steel sheets, cut from coils, serve specific applications. Recognizing these distinctions is crucial when selecting the appropriate steel form for a particular project or manufacturing process.

- Q: Looking for an insight here into what hiking with steel toe-capped boots would be like, as I saw a nice pair of steel toed magnums that I plan to use for my future hiking (which I will be doing a fair amount of in the future). They seemed fairly comfortable, but I am curious into what others have to say and what might be known of this sort of approach. Thanks in advance.

- They are very heavy not like hiking boots but it is your choice

- Q: What are the dimensions of steel coils used in the railway equipment industry?

- The dimensions of steel coils used in the railway equipment industry can vary depending on the specific application and requirements. However, common dimensions for railway steel coils typically range in thickness from 1.5mm to 25mm and in width from 600mm to 2000mm. The inner diameter of the coil is typically around 508mm, while the outer diameter can range from approximately 900mm to 2000mm.

- Q: How do steel coils compare to other materials like aluminum or copper?

- When comparing steel coils to other materials like aluminum or copper, it is evident that they possess both advantages and disadvantages. One primary advantage of steel coils lies in their remarkable strength and durability. Steel is renowned for its high tensile strength, enabling it to withstand heavy loads and high stress without any deformation. As a result, steel coils are highly suitable for various applications that demand robust and resilient materials, including construction, automotive manufacturing, and transportation industries. In contrast, aluminum and copper are generally softer and less strong than steel, rendering them less appropriate for heavy-duty tasks. Another advantage of steel coils is their cost-effectiveness. In comparison to aluminum or copper, steel is a relatively inexpensive material, making it a more accessible option for large-scale projects or mass production. Furthermore, steel is highly recyclable, contributing to its cost-effectiveness and sustainability. Nonetheless, steel coils do have some disadvantages when compared to aluminum or copper. One notable drawback is their weight. Steel is significantly denser than aluminum or copper, resulting in heavier steel coils that can be more challenging to handle and transport. This disadvantage can prove to be critical in industries where weight plays a vital role, such as aerospace or electrical applications. Additionally, steel coils are susceptible to corrosion, which is another disadvantage. While aluminum and copper possess natural corrosion resistance, steel is prone to rust and oxidation. Consequently, steel coils require proper protection and coating to prevent corrosion, which adds to the overall cost and maintenance requirements. In conclusion, steel coils offer exceptional strength, durability, and cost-effectiveness when compared to aluminum or copper. However, they are generally heavier and more prone to corrosion. Ultimately, the selection between steel, aluminum, or copper will depend on the specific application, budget, and project requirements.

- Q: What are the different methods of surface inspection for steel coils?

- Some of the different methods of surface inspection for steel coils include visual inspection, magnetic particle inspection, dye penetrant inspection, eddy current inspection, and ultrasonic inspection.

- Q: How are steel coils used in the manufacturing of wires?

- Steel coils are used in the manufacturing of wires by being fed into wire drawing machines, where they are gradually reduced in diameter through a series of dies. The steel coils serve as the initial raw material, providing the necessary strength and flexibility for the wires to be produced.

- Q: what do you think about producebility of low density steel? for example: can density of 1020 steel (or ony others) be decreased without any loss of other properties.

- 1. A method has been developed for magnetic phase analysis of Fermanal type alloys as-quenched and after aging. 2. The upper limit of alloying to ensure the optimal mechanical properties was determined more precisely for steel 9G28Yu9MVB. For rods aged at 550°C for 16 h the aluminum content should not exceed 9.2% and the carbon content 0.92%. 3. To ensure the optimal mechanical properties of the deformed metal it is necessary to obtain a fine-grained single-phase austenitic structure after quenching. The amount of hardening phase after quenching should not exceed 15–20% (saturation magnetization around 1600 G).

- Q: What are the current trends in the steel coil industry?

- Some current trends in the steel coil industry include the increasing demand for high-strength steel coils due to their durability and lightweight properties. There is also a growing focus on sustainability and environmentally friendly practices, leading to the development of eco-friendly coatings and recycling initiatives. Additionally, digitalization and automation are becoming more prevalent, enhancing efficiency and productivity in steel coil manufacturing processes.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Coil/PPGI Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords