Pre-Painted Galvanized/Aluzinc Steel Coil from China in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

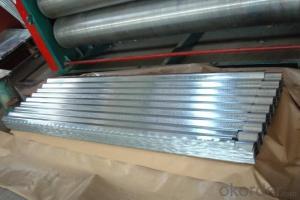

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of construction scaffolding?

- Steel coils are used in the manufacturing of construction scaffolding as they are processed and formed into various structural components such as tubes, pipes, and frames. These coils are often cut, bent, and welded to create sturdy and durable scaffolding structures that can support the weight of workers and materials during construction projects.

- Q: i need this for school and i need to know what are some advantages of stainless steel.

- 313 times as resistant to rust and corrosion as mild steel. 30% stronger and more durable than mild steel. 15% more conductive than mild steel. Easily wiped clean. Scratches can be easily polished out.

- Q: Hello. No freakin' website has no dam info on what products have carbon steel in them. I know it's in cooking equipment and tools, but what tools?i.e It's in a wrench or strainerSo what products have carbon steel in them?

- there are too many products that have carbon steel in them. just ask yourself whether it rusts, if it does then it has carbon steel. If not then it probably isn't.

- Q: How is the critical temperature of structural steel affected by fireproofing? What temperatures can fireproofed structural steel withstand?

- mix the fire retardant with cement, let it harden fast to superstructure. this will create better stability and will not be dislodged in case of impact.

- Q: What is the difference between cold rolled strip and cold rolled steel coil?

- A simple point is the difference between a strip and a volume. Strip is the flat strip of cold rolling, which is further processed on the basis of flat strip and rolled into thinner and can be rolled up,

- Q: I am reading the book The Cure For All Advanced Cancers by Hulda Regehr Clark.She writes for example: cancer can be caused by exposure to heavy metals, like nickel and chromium from stainless steel cookware. Stainless steel cookware releases chromium and nickel, two of the most carcinogenic metals.Are there any studies done measuring how much nickel and cadmium can be released from the regular use of stainless steel cookware?Is this a commonly accepted opinion that use of stainless steel cookware is dangerous?If not stainless steel, what kind of cookware to use? I heard that non-stick cookware also releases some harmful chemicals.

- perfluorooctanoic acid is a chemical used to make nonstick cookware. It has been shown to cause cancer in lab animals. The epa has asked companies that use that chemical to phase it out of the cookware, just in case. But it has not been shown to cause cancer in humans. Stainless is not known to cause any type of health problems. Cast iron is healthier and anodized aluminum is great too.

- Q: How do steel coil manufacturers meet customer specifications?

- Steel coil manufacturers meet customer specifications by carefully analyzing the requirements provided by the customer and utilizing advanced production techniques to ensure precise dimensions, mechanical properties, and surface finishes. They employ strict quality control measures throughout the manufacturing process, including rigorous testing and inspections, to ensure that the coils meet the specified standards. Additionally, manufacturers often collaborate closely with customers to understand their unique needs and provide customized solutions that meet or exceed their expectations.

- Q: How are steel coils used in the production of shipbuilding materials?

- Steel coils are used in the production of shipbuilding materials as they are typically cut and shaped into plates, sheets, or beams that are then used to construct various components of a ship's structure such as the hull, decks, and bulkheads. The coils provide a reliable and durable base material that can withstand the harsh marine environment and ensure the structural integrity and strength of the ship.

- Q: How do steel coils contribute to the manufacturing of steel furniture?

- The manufacturing of steel furniture heavily relies on steel coils, which play a critical role. These coils, constructed from top-notch steel, act as the primary raw material for the production of various furniture items. To begin with, the framework and structure of steel furniture are created using steel coils. Manufacturers can easily cut, shape, and weld these coils into different sizes and shapes, allowing them to produce robust and enduring furniture frames. The flexibility of steel coils enables the production of furniture with intricate designs and distinctive shapes, providing both functional and aesthetic value. Additionally, steel coils are utilized to fabricate springs for furniture like sofas and chairs. The elasticity and strength of these steel coils make them ideal for crafting comfortable and supportive seating options. The coils are meticulously shaped and integrated into the furniture, ensuring that the seating surface offers the necessary resilience and flexibility for a comfortable experience. Moreover, steel coils contribute to the overall durability and longevity of steel furniture. Steel is renowned for its high tensile strength and resistance to wear and tear, making it an excellent choice for furniture subjected to heavy use and weight load. By utilizing steel coils, the furniture can endure years of regular use without compromising its structural integrity. Furthermore, steel coils are often treated with various finishes and coatings to enhance their appearance and protect them from corrosion. These coatings can be applied to the coils prior to shaping them into furniture components, guaranteeing that the final product maintains its aesthetic appeal and remains resistant to rust and other forms of damage. In conclusion, steel coils are a vital component in the manufacturing of steel furniture. They provide the necessary strength, flexibility, and durability required to create sturdy furniture frames, comfortable seating surfaces, and long-lasting products. The absence of steel coils would render the production of steel furniture impossible, compromising the quality and performance of the final products.

- Q: I was wondering whether anyone knew if painted steels rusts at the same speed as steel that isn't painted. Also, does steel rust quicker than aluminium?Thank you

- Painting a piece of steel will coat it with a protective layer, causing it to not rust (not get oxidised). Aluminum does not rust.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil from China in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords