Pre-Painted Galvanized/Aluzinc Steel Coil for Portable House

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

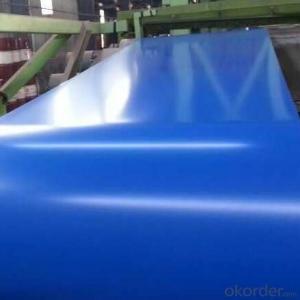

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the different coil cutting methods used for steel coils?

- There are several coil cutting methods commonly used for steel coils, each with its own advantages and applications. These methods include shearing, slitting, and laser cutting. 1. Shearing: Shearing is a widely used method for cutting steel coils. It involves applying a high force to a set of blades, which cuts through the coil in a straight line. Shearing is ideal for cutting thick steel coils into smaller, more manageable sizes. It is a cost-effective method that can be used for high-volume production. 2. Slitting: Slitting is a process that involves cutting a wide coil into several narrower strips. This method is commonly used for steel coils that need to be transformed into various widths, such as those used in the manufacturing of automotive components, construction materials, and electrical appliances. Slitting machines use a set of circular knives to make precise cuts, ensuring minimal material loss and high accuracy. 3. Laser cutting: Laser cutting is a more advanced method that uses a high-powered laser beam to cut through steel coils. This process offers exceptional precision, allowing for intricate designs and complex shapes to be cut with ease. Laser cutting is suitable for thin to medium thickness steel coils and is often used in industries that require high-quality cuts, such as automotive, aerospace, and electronics. Each of these coil cutting methods has its own advantages and is chosen based on the specific requirements of the steel coils being processed. Factors such as coil thickness, desired accuracy, production volume, and the complexity of the cuts needed are all taken into account when determining the most appropriate cutting method.

- Q: What are the environmental benefits of using steel coils?

- There are several environmental benefits of using steel coils. Firstly, steel is a highly recyclable material, meaning that it can be reused multiple times without losing its properties. This reduces the demand for raw materials and minimizes waste. Additionally, steel coils have a long lifespan, making them durable and resistant to wear and tear. This reduces the need for frequent replacements, saving resources and reducing waste. Furthermore, steel is a highly energy-efficient material, both in its production and during its use. It requires less energy to manufacture steel coils compared to other materials, and its high strength-to-weight ratio allows for lighter structures, reducing energy consumption in transportation. Overall, the use of steel coils contributes to a more sustainable and eco-friendly approach in various industries.

- Q: Can solution annealing be done on carbon and low alloy steels. please give an explanatory answer.

- No. Carbon steel has two different crystal structures, FCC and BCC , depending on the temperature. when you heat steel up and then quench it, it locks the crystal structure into the BCC form. this makes it hard. whereas precipitation hardened austentic stainlesses remain BCC regardless of the temp, so the hardness change is not a function of thermally induced strain. you can anneal carbon steel but the thermal profile is closer to the precipitation profile of PH stainlesses than it is to the Solution annealing profile.

- Q: What are the different types of steel finishes for coil protection?

- There are several types of steel finishes used for coil protection, including galvanized, painted, and coated finishes. Galvanized finish involves applying a layer of zinc to the steel surface, providing corrosion resistance. Painted finishes involve applying a layer of paint to the steel surface, offering both aesthetic appeal and protection against corrosion. Coated finishes typically involve the application of a protective coating, such as epoxy or polyurethane, to the steel surface, providing enhanced durability and resistance to various environmental factors.

- Q: Or is it a coating that is applied? If so what types of steel? Or what types of coatings?

- there is a weathering steel that corrodes and then stops. The outer surface of the steel is a rusty looking brown but after the first layer of rust appears, the process stops. It used to be called A588 steel. So called mild steel is not A36 anymore, it is A992 (50 ksi yield). The only material that is A36 anymore are angles, channels, and plate. You can coat the steel with an epoxy coating to protect the steel from this highly corrosive environment. Google a company called TNEMEC. They offer epoxy coatings for steel and other coatings. Weathering steel and epoxy coating are not cheap options.

- Q: What are the different types of steel coatings for coils?

- There are several different types of steel coatings for coils, including galvanized coatings, galvannealed coatings, aluminized coatings, and organic coatings.

- Q: What are the key players in the steel coil manufacturing industry?

- Large multinational companies with significant market share and influence dominate the steel coil manufacturing industry. Among the prominent players are: 1. ArcelorMittal, the world's largest steel producer, operates in over 60 countries and offers a diverse product portfolio. 2. Nippon Steel Corporation, a leading Japanese steelmaker, holds a prominent position in the global steel coil manufacturing market, particularly in the automotive and construction sectors. 3. POSCO, based in South Korea, is renowned for its high-quality steel products and advanced technology in steel coil manufacturing. 4. Baosteel Group Corporation, the largest steel manufacturer in China and globally, boasts a vast range of steel products, including steel coils, and excels in research and development capabilities. 5. Thyssenkrupp AG, a German multinational conglomerate, plays a significant role in the steel coil manufacturing industry, focusing on innovation and sustainability across a diverse product range. 6. United States Steel Corporation, a leading American steel producer, holds a crucial position in the steel coil manufacturing industry, particularly in the automotive, construction, and energy sectors. 7. JFE Holdings, Inc., a Japanese steel conglomerate, is a key player in the steel coil manufacturing industry, known for its customer-oriented approach and high-quality steel products. These companies represent a fraction of the key players in the steel coil manufacturing industry, as numerous others contribute to this sector. The industry is highly competitive, and these companies consistently strive to innovate, enhance efficiency, and meet the evolving demands of the market.

- Q: And by how much? I'm pretty sure that sterling silver is stronger, but I'm wondering if I could still use a metal stamp to stamp into something that's stainless steel - if it would be soft enough?

- No way steel is by far stronger. Tensile strength of Sterling silver 207 MPa Tensile strength of Stainless Steel 515 MPa

- Q: Why do we galvanise steel? Galvanised steel is steel coated with zinc.

- We galvanize steel to protect and prevent steel from rusting or corrosion. Rusting, for the most part is a layman's term that has been used exclusively to describe the chemical OXIDATION reaction of steel or iron with oxygen forming a reddish brown substance called rust. Zinc metal coating also oxidizes but does not form the reddish brown rust. Instead, it forms an oxide, just like the rust, which is iron oxide. The protection created by zinc is because it is more reactive to oxidizers, than steel or iron. Thus, the oxidizer will react with Zinc first before it will react with Iron, hence protecting iron. If the zinc is fully reacted then iron is next. BUT, the zinc oxide formed on the surface of the steel or iron is no longer reactive to oxygen and also creates a good physical barrier so that oxygen will not have chance to even have contact with the underlying steel. Isn't that neat! Here is chemistry at one of its useful best.

- Q: I need steel toe shoes for a workplace, where can I get them?I live in Surrey,UK.

- steel okorder

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil for Portable House

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords