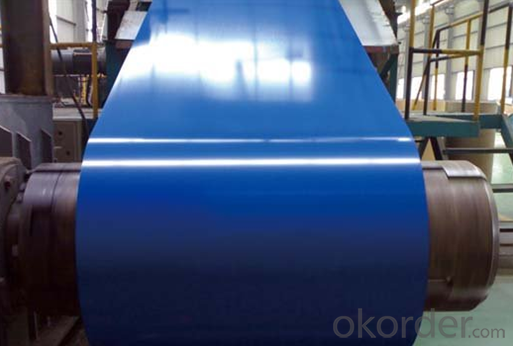

Pre-Painted Color Coated Galvanized Steel Coils/Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-Painted Color Coated Galvanized Steel Coils/PPGI

Product Description

Prepainted Galvanized Steel Coil PPGI Steel Coil

1) Quality standard of Prepainted Galvanized Steel Coils: JIS G3312 CGCC & CGLCC

2) Grade of Prepainted Galvanized Steel Coils: CGCC and CGLCC

3) Hardness of Prepainted Galvanized Steel Coils: Both soft and hard quality are available

4) Surface finish of Prepainted Galvanized Steel Coils: With or without protect film

5) Thickness of Prepainted Galvanized Steel Coils: 0.14-1.20 mm

6) Width of Prepainted Galvanized Steel Coils: 914mm, 1000mm, 1220mm and 1250mm, width 600-1250mm is available

7) Finish by coil or sheet for Prepainted Galvanized Steel Coils: Both sheet and coil are available

8) Zinc coating of Prepainted Galvanized Steel Coils: 60-275G/M2, both sides

9) Paint thickness for top side of Pre-painted Galvanized Steel Coils: 5 micron primer + (10-20) microns modified polyester, any RAL color code.

10) Paint thickness for back side of Pre-painted Galvanized Steel Coils: (5-10) microns Epoxy

11) Weight per Pre-painted Galvanized Steel Coils: 4-6 tons, also can be upon customer's requirements

12) Max loading weight in one 20ft container for Pre-painted Galvanized Steel Coils: 25 tons generally

13) MOQ of prepainted steel coils: 25 tons for each item;

14) Actual shipping quantity of Pre-painted Galvanized Steel Coils: More or less 10% generally;

15) Delivery time for Galvanized Steel Coils: 15 days ganerally.

16) Applications of Galvanized Steel Coils: Widely used for roofs, outer walls, ovens, explosive-proof steel, electrically controlled cabinets, and industrial freezers in the residential and industrial buildings.

Aluzinc

Color: RAL, or other series

Standard: JIS G3302, JIS G3312, ASTM A653M/A924M 1998

Prepainted Steel Coil Features Specifications:

Grade: Q195 - Q235 and 08AL, SPCC, SPCD, SPCE, 08.10.15, SGCC (DX51D+Z) SGCD(DX52D+Z) etc.

Surface treatment: Chromated, unoiled/oiled, bright finished, spangle, fingerprint resistance.

Surface protection: PE, PVDF, SMP, HDP, etc.

Thickness: 0.20mm-2.0mmWidth: 1000mm, 1200mm, 1250mm, 1500mm, or according to your request.

Zinc coating: 80g-275gsmcoil weight: 3-27 tons

Paint: Polyester silicon modified polyester, PVC sol, polyvinylidene chloride.

Exact Rate As Per Your Request.

We Attach Colour Card In Pic, So It Is For Your Reference.

Back painting: | 5-7 mic. EP |

Color: | According to RAL standard |

commodity | Color-coated Galvanized Steel Coil (PPGI/ PPGL) |

Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

Types: | For general / drawing use |

Thickness | 0.14-1.0mm(0.16-0.8mm is the most advantage thickness)) |

Width | Width: 610/724/820/914/1000/1200/1219/1220/1250mm |

Type of coating: | PE, SMP, PVDF |

Zinc coating | Z60-150g/m2 or AZ40-100g/m2 |

Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

ID coil | 508mm / 610mm |

Coil weight: | 4--8MT |

Package: | Properly packed for ocean freight exportation in 20' ' containers |

Application: | Industrial panels, roofing and siding for painting / automobile |

Price terms | FOB, CFR, CIF |

Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

delivery time | 25 days after recepit of 20% TT |

Remarks | Insurance is all risks |

MTC 3.1 will be handed on with shipping documents | |

We accept SGS certificatation test |

FAQ

1. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20- 40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

2.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3. Is the sample available?

Yes, samples can be sent for test if you need.

- Q: What are the different types of steel coil coatings for corrosion resistance?

- There are several different types of steel coil coatings that are specifically designed to provide corrosion resistance. These coatings can be categorized into two main types: organic coatings and metallic coatings. 1. Organic Coatings: - Polyester: Polyester coatings are commonly used for steel coil applications due to their excellent corrosion resistance and durability. They offer good weatherability and resistance to chemicals, making them suitable for outdoor applications. - Polyvinylidene Fluoride (PVDF): PVDF coatings are highly resistant to UV radiation, weathering, and chemicals. They provide exceptional durability and are often used in demanding environments such as coastal areas or industrial settings. - Polyurethane: Polyurethane coatings offer excellent abrasion resistance and provide a high level of corrosion protection. They are commonly used in applications where there is a higher risk of mechanical damage or exposure to harsh conditions. - Epoxy: Epoxy coatings provide excellent adhesion and chemical resistance. They are often used in industrial applications where resistance to chemicals, solvents, and oils is required. 2. Metallic Coatings: - Galvanized Coatings: Galvanized coatings involve applying a layer of zinc to the steel surface through a hot-dip or electroplating process. This creates a barrier between the steel and the surrounding environment, providing effective corrosion protection. Galvanized coatings are widely used in various industries due to their cost-effectiveness and good durability. - Galvannealed Coatings: Galvannealed coatings are similar to galvanized coatings but undergo an additional heat treatment process. This results in a coating with increased hardness and improved paint adhesion, making it suitable for applications that require additional surface protection or paintability. It is important to consider the specific requirements of the application and the level of corrosion resistance needed when selecting the appropriate steel coil coating. Consulting with coating manufacturers or industry experts can help determine the most suitable coating for a particular application.

- Q: How are steel coils used in the aerospace industry?

- Steel coils are used in the aerospace industry for various applications including manufacturing aircraft components, structural supports, and engine parts. The coils are typically processed and shaped into specific forms such as sheets or plates, which are then used to construct critical components of aircrafts, ensuring strength, durability, and performance.

- Q: What are the challenges in coil slitting for thin gauge materials?

- Successfully operating coil slitting for thin gauge materials involves addressing a specific set of challenges. One major challenge is ensuring the proper handling and stability of the thin gauge material. The material's susceptibility to deformation, wrinkling, or tearing increases as it becomes thinner. To tackle this, careful attention must be given to the handling equipment and techniques used during the slitting process. This is necessary to maintain the appropriate tension and support throughout the operation. Another challenge is maintaining consistent and precise slitting widths. Thin gauge materials are often used in applications where accuracy is crucial, such as electronic components or automotive parts. Any variation in the slitting width can cause functional defects or assembly problems. Achieving precise slitting widths in thin gauge materials requires the use of high-quality slitting knives, well-maintained slitting machinery, and accurate tension control systems. In addition, thin gauge materials are more prone to surface defects, such as scratches or burrs, during the slitting process. These defects can impact the material's appearance, performance, or even its safety. To minimize the occurrence of surface defects, it is important to carefully select slitting knives and regularly maintain the slitting machinery. Furthermore, thin gauge materials often possess a higher yield strength, making them more resistant to deformation. This poses a challenge when it comes to achieving clean and straight edges during the slitting process. Special considerations must be taken to ensure that the slitting knives are sharp and properly aligned, allowing for clean cuts without introducing any edge defects. Lastly, thin gauge materials are generally more sensitive to external factors such as temperature, humidity, or static electricity. These factors can affect the material's dimensional stability, resulting in variations in slitting width or other quality issues. Therefore, it is crucial to establish appropriate environmental conditions and implement effective anti-static measures to minimize the impact of these factors. To summarize, the challenges associated with coil slitting for thin gauge materials revolve around handling and stability, maintaining precise slitting widths, minimizing surface defects, achieving clean and straight edges, and mitigating the influence of external factors. Overcoming these challenges requires a combination of suitable equipment, techniques, and operational controls to ensure high-quality slitting outcomes.

- Q: Do any tour players use steel shafted woods? And are there any real advantages to having steel shafted woods? I have only played with one person to use steel shafted woods, he tells me thats because he cant hit it straight with graphite, however he is a very short hitter.

- Graphite shafts are generally better for the amateur golfer. Graphite shafts are more forgiving than stell shafts. With graphite shafts, it is easier to get the ball in the air, and keep your ball trajectory always with good height. For SOME above average golfers and tour professionals, steel shafted woods find their way into their bags. This is because steel shafts have the ability of being more precise in terms of direction. However, to hit steel shafted woods, you need a lot of power and a slightly faster than normal tempo. Point is, if your a golfer that plays this sport for the leisure, or don't want to be stressed, take the graphite shafts. But if you're a single-digit handicapper, and feel you're physically fit ALL THE TIME, then go ahead and try the steel shafts.

- Q: How are steel coils protected during transportation?

- Steel coils are typically protected during transportation by being wrapped in layers of protective materials such as plastic or paper, and then secured onto pallets or placed inside specialized containers. This helps prevent damage from moisture, dust, and other external elements, ensuring the coils arrive at their destination in good condition. Additionally, proper handling and loading techniques are employed to minimize the risk of any physical damage during transportation.

- Q: How are steel coils protected during storage and transportation?

- Steel coils are typically protected during storage and transportation through various methods such as applying anti-corrosion coatings, wrapping them in protective materials like plastic or paper, and securing them with strapping or banding to prevent damage or movement.

- Q: How are steel coils inspected for surface finish variations?

- Steel coils are inspected for surface finish variations by using techniques such as visual inspection, magnetic particle inspection, and surface roughness measurement.

- Q: What are the dimensions of steel coils used in the electrical equipment industry?

- The dimensions of steel coils used in the electrical equipment industry can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry range from 0.25mm to 3mm in thickness and 600mm to 2000mm in width. The inner diameter of the coil is typically around 508mm, while the outer diameter can vary from 800mm to 2000mm. These dimensions ensure compatibility with various electrical equipment manufacturing processes and enable efficient production.

- Q: I bought my Gerber Scout for 29 bucks at the local Walmart a couple months ago, and so far it's performed better than any of my previous knives (a couple of low quality Bucks, and a Winchester). However, my friend just bought a 50 dollar Buck knife and I absolutely love it, so I'm debating trading mine in and pitching in a bit of cash for the same kind.What troubles me is the fact that everybody seems to be bashing 440A steel. I hear a lot of bad things about it; how it is soft, chips easy, dull quickly, etc. How bad is 440A steel really, and would it be worth trading in my Gerber plus about 30 cash for a Buck Vantage Pro? Apparently the Vantage Pro uses S30V steel, so is it really that big of an upgrade, from 440A to S30V? Thank you.

- 440 steel is fine for most knives, but there are better quality steels out there for specialized uses. If you like the knife you have, don't worry about what other people say. If you like the new knife more, trade for it. Sometimes I question why people have to ask so many questions about what's better than what.

- Q: What are the common processing defects in steel coils?

- Steel manufacturers must identify and rectify the following processing defects commonly found in steel coils: 1. Coil breaks: These occur when the steel strip breaks during the process of winding the coil. Improper tension control or material defects can cause these breaks. 2. Slivers: Thin, elongated steel pieces get trapped in the coil during the rolling process. Foreign materials, scale, or defects in the rolling mill can cause slivers. 3. Edge cracks: Cracks appearing along the edges of the coil are known as edge cracks. Improper edge trimming, material defects, or excessive rolling forces can cause these cracks. 4. Surface defects: Scratches, pits, or scars on the steel coil constitute surface defects. Handling issues, improper cleaning, or rolling mill defects can cause such defects. 5. Coil set: Coil set refers to the coil's tendency to retain a curvature even after it has been uncoiled. This can occur due to uneven cooling during the rolling process or improper tension control. 6. Oil spots: Stains or discolorations on the steel coil caused by residual oil or lubricants are known as oil spots. Inadequate cleaning or incorrect lubricant application can lead to oil spots. 7. Wavy edges: Irregularities or waves along the edges of the steel coil are referred to as wavy edges. Uneven rolling forces or improper edge trimming can cause these irregularities. 8. Lamination: Lamination defects occur when layers or sheets of steel are not properly bonded together. Material defects or improper rolling conditions can cause lamination defects. 9. Burr: A raised edge or roughness along the edge of the steel coil is called a burr. Improper trimming or cutting processes can cause burrs. 10. Non-uniform thickness: Non-uniform thickness refers to variations in the thickness of the steel coil. Uneven rolling forces, improper cooling, or material defects can cause non-uniform thickness. Identifying and addressing these processing defects is crucial for steel manufacturers to ensure the quality and reliability of their steel coils.

Send your message to us

Pre-Painted Color Coated Galvanized Steel Coils/Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords