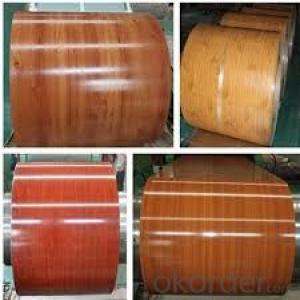

Color Steel Rolled/Printed Color Coated Sheet /Rough and Glossy Wood Grain Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Product Name: China PPGI manufacturer/PPGI MILL

PPGI coils

PPGI steel coils

PPGI galvanized coils

PPGI zinc coated coils

Pre-painted galvanized steel coils

Color coated steel coils

Color coated steel coils

Red color/blue color steel coils

Color coated PPGI FOR metal roof

DX51D color coated corten steel coil(PPGI)

Prime prepainted galvanized steel coil

White color prepainted steel coils

Color steel coil for roofing material

Dx51d+z prepainted steel coil

Colorful galvanized steel coil

Specifications:

Grades: Q195-Q235 and SPCC, SPCD, SPCE, SGCC (DX51D+Z) and SGCD (DX52D+Z)

Thickness: 0.13 to 2.0mm

Width: 600 to 1200mm or customized

Coil inner diameter: 508 to 610mm

Coil weight: Customized

Color: RAL

Surface protection: PE, PVDF, SMP and HDP

Surface treatment: Chromate, oil/un-oil, bright finish, spangle and anti-finger print

Standards: JIS G3302, JIS G3312 and ASTM A653M/A924M 1998

Zinc coating weight: 60 to 275G/M

Features:

Nice corrosion-resistant: Zinc layer provides nice protection of pre-painted galvanized steel sheet

High heat resistant: Reflective surface of material aids in efficiently reflecting sunlight away and turn reducing amount of heat transmitted, thermal reflectivity converts into energy-saving.

Coating adhesive force of color-coated sheet is strong, which keeps color and luster novel for long.

Widely used in such field as architecture, electrical home appliances, furniture, communal facilities, communications and transportation.

PPGI prepainted sheets and coils

Product thickness: 0.135 to 2.0mm

Product width: 760 to 1250mm

Coil weight: 5 to 10 metric tons

Coil ID: 508mm

Coil OD: Max 1500mm

Coating type: PE

Standards: JIS G 3312, ASTM A755M, GB/T 12754, Q/CHG 2-2003, EN 10143, DIN 17162

Material: TDC51D, AZ150, SGCC, CGCC, SPCC195L, TSGCC, CCGI, Q195-Q235, SPCD, SPCE

Color: RAL

Zinc coating: 60 to 275G/M²

Application: Construction, hardware, home appliances, interior decoration and more.

| NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC | |

| CERTIFICATE | ISO9001:2008 | |||

| STANDARD | EN10142 JIS G3302 GB/T-12754-2006 | ASTM A653 JIS G3302 SGCC/SGCH GB/T2518 European Standard | ASTM A792 JIS G3321 JIS G3317 | |

| GRADE | CGCC CGCH CGCD1-CGCD3 CGC340-CGC570 GRADE | SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R | |

| MODEL NO | 0.16MM-1.5MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER | |

| TYPE | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | |

| TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled - galvanized | Hot rolled-cold rolled -galvalume /Aluzinc | |

| SURFACE TREATMENT | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating | ||

| APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family | |||

| SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | |||

Q&A Acceptable price term

ANSWER: FOB CNF CIF DDU CPT

- Q: Well the other day i told my friend that when you put a compass near steel it will screw up and he said only magnets do that then i showed him and it worked then he said: that'ss because steel has its own magnet in it coz it builds up static electricity is that correct what he said? thanks

- No. Steel does not build up static electricity by itself. Also, magnetic fields are made by moving electricity, not static electicity. The steel conducts magnetism, so it changes the earth's magnetic field near itself by conducting the field through itself. The larger effect is a magnet near a piece of steel: the compass has a magnet, and when you place it near a ferromagnetic material, it attracts. Try putting a refridgerator magnet against the fridge - it sticks because it attracts.

- Q: Just wondering how good are forge steel screw drivers, tool boxes(organisers) and pliers are, as screw fix are having a january sale, and looking to add to my tool collection. Thanks in advance

- forged steel is a trick to get people like you who know nothing of steel to think of a blacksmith hammering away at a anvil making great tools. Not to say they are bad they are probably fine. but forged just means it was made when the steel was hot, it says nothing of the quality of steel in the process. however whenever steel is forged it will be stronger than the same product made out the same steel, but shaped by machining process.

- Q: i'm looking into pedal steel guitars, and I would like some suggestions or links and info on what kind i should get.

- Try okorder -The Art of Steel Guitar/ Steel guitar players -Take it away Leon- McAuliffe and 'Speedy West' were a couple greats. In the late '50s, Speedy was playing a Fender 1000 Pedal steel. He often did duets with Jimmy Bryant The Fastest Guitar Player In The Country! / note also the 'Emmons Guitar Company':

- Q: What is the minimum order quantity for steel coils?

- The minimum order quantity for steel coils varies depending on the supplier and specific product. It is recommended to contact the supplier directly to inquire about their minimum order requirements for steel coils.

- Q: What are the different grades of steel used in manufacturing steel coils?

- The different grades of steel used in manufacturing steel coils include low carbon steel, medium carbon steel, high carbon steel, and stainless steel.

- Q: What are the different methods of coil recoiling for steel coils?

- There are several methods of coil recoiling for steel coils, including slitting, rewinding, and recoiling. Slitting involves cutting the coil into narrower strips, while rewinding involves unwinding the coil and rewinding it onto a new spool. Recoiling, on the other hand, is the process of rewinding the coil onto the same spool. These methods allow for the customization of coil width and length to meet specific requirements and facilitate easier handling and transportation.

- Q: melting point, as compare to stainless steel

- Be *real cautious* using HCL round stainless. A lowering acid like HCL will wreck down the oxide layer on the stainless, and corrosion will proceed. So far as i do know, there is not any scale down level at which HCL will not attack the skin oxide, however at very low concentrations maybe somewhat rust/pitting/corrosion is not going to be a main issue. Oxidizing acids like nitric, and to a couple measure sulfuric, will passivate stainless under the right conditions. But on simple, mild steels, corrosion will proceed to form FeCl and FeSO4 corrosion merchandise. The corrosion will haven't any outcomes on tensile, hardness or affect until ample fabric has been eliminated via corrosion to make a measurable change. Hydrogen embrittlement is a likelihood if there's constant anxiety, and hydrogen is advanced in corrosion. Whether or not it is a challenge would rely on the drawback.

- Q: How are defects in steel coils detected and resolved?

- Defects in steel coils are typically detected through visual inspections, as well as non-destructive testing techniques such as ultrasonic testing and magnetic particle inspection. Once identified, the defects can be resolved through various methods including grinding, welding, or cutting and replacing the affected area. The specific resolution method depends on the nature and severity of the defect.

- Q: How are steel coils used in the manufacturing of drivetrains?

- Steel coils are used in the manufacturing of drivetrains as they provide the necessary strength and durability required for various components such as gears, shafts, and bearings. These coils are often shaped and machined to create specific drivetrain parts that can withstand the high pressures and forces involved in transferring power from the engine to the wheels.

- Q: I want to replace the old refrigator within the next 6 months........ Is the trend to buy a stainless steel refrigerator? Some magazines and internet sites are pointing me that direction. What are the pro's and con's ? I like the color bisque, or cream-color as well, or better, than stainless steel. What would be the reasons to buy stainless steel...is it becoming the most popular color ?

- I think it's just the popular choice at the moment like avocado green was the hottest thing in the 1970s. I bought a Whirlpool Sateen. It has the look of stainless steel, but magnets will stick to it. There is no functional difference.

Send your message to us

Color Steel Rolled/Printed Color Coated Sheet /Rough and Glossy Wood Grain Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords