Pre-painted Aluzinc Steel Coils with Best Quality Competitive Price in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Aapplication of Galvanized steel coil

Galvanized steel coil is a special type of steel coil used in a number of different applications within fabrication and manufacturing environments. Steel coil of any kind is flat stock that is thin enough to be rolled into a coil or wound into a continuous roll. It is also able to be rolled out flat and cut at any length or shape needed. Having the steel coil galvanized helps the user by allowing it to be applied in outdoor fabrication projects.

2.Advantage of Our Organization:

We specialize in this field in China concerning GI, GL, PPGI, PPGL, Corrugated Steel sheet, we know the suppliers, the price, the domestic market and the price trend very well, we have sufficient information about various stocks, diffrient price, we update these information everyday.

3.Details of Galvanized steel coil:

Standard | ASTM,GB,JIS |

Grade | DX51D+Z,SGCC |

Thickness | 0.1-1.5MM |

Width | 914,1000,1219,1250MM |

Coil weight | 3-6mts |

Top paint | 22MIL |

Back paint | 11MIL |

Surface treatment | color coated/galvanized/galvalume |

Delivery time | 10-20 working days |

Packing : | waterproof paper, galvanized steel covered and steel strip packed |

USeage | widely used in construction,home,appliance,decoration,wear resistant steel,etc |

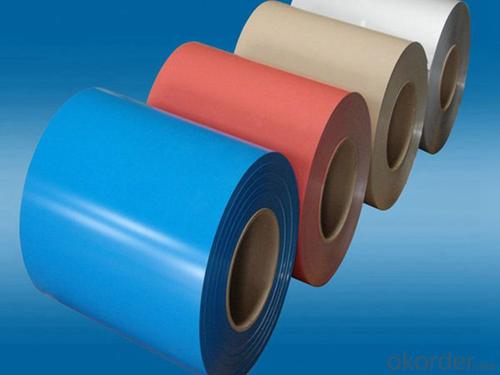

4.Galvanized steel coil images:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of steel coils in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: I heard on some shows that you can carbonise steel by heating it red hot then dropping it in black oil. i cant find this no where online, and the process for commercial carbon steel is totally different. can you really carbonise regular steel by heating it to red hot then dropping it in regular black oil. i saw it on mythbusters once. when the made carbon steel hammers to test if 2 hammers smashed together will shatter

- in the experience that your speaking a pair of folding pocket knife, i think of that it somewhat is somewhat six one way and a 0.5 dozen the different. i actually do choose stainless for my pocket knives. i don't choose to grease a knife to the degree i've got faith carbon demands, basically to then stick it my pocket to entice dirt to the knife and oil to my pants. i'm the impressive opposite on sheath knives nevertheless. i admire 1095 carbon steel, uncomplicated part sheath knives. i will thrash on them difficult, and that i rarely have considerable part issues. of course, I require them to be lined with some style of powder coat or the like, with the aid of fact they might rust, yet I do attempt and save them sparkling and dry whilst in the sheath, so as that they gained't pit the uncoated part. My motives for this sheath knife selection is multi-fold. First, those knives are only much less costly. i don't spend $80 money on a exterior sheath knife. i take advantage of the gadget too difficult to choose to spend extra. i don't basically like the extra classic stainless steels alongside with AUS-8, 420HC, and 440C (to not point out the HORRENDOUS 440A) with the aid of fact i've got faith that the all else being equivalent, a stainless blade will bend till now a carbon blade will harm. I additionally think of that carbon holds an part a minimum of besides, if not extra suited, than classic stainless, and it somewhat is plenty extra handy to hone. i don't understand plenty approximately those new laminates, different than the very difficult, yet not so difficult. they seem probably too brittle for my use. That, mixed with the actuality that they harm the bank, ability that I only is only not pondering them.

- Q: How are steel coils used in the production of electrical connectors?

- Steel coils are used in the production of electrical connectors as they provide a strong and durable core component. The coils are wound into the desired shape and size, and then further processed to create the necessary conductive pathways for electrical current. This ensures stability, strength, and efficient conductivity in the connectors, making them suitable for various electrical applications.

- Q: How are steel coils processed and treated?

- Steel coils are processed and treated through a series of steps to ensure their quality and suitability for various applications. The process begins with uncoiling the steel coil, which involves removing the outer layers of protective wrapping and unwinding the coil. Once uncoiled, the steel is inspected for any defects, such as cracks or uneven surfaces. Next, the steel coil goes through a cleaning process to remove any dirt, oil, or rust present on its surface. This is typically done using a combination of chemical cleaning agents and mechanical scrubbing. After cleaning, the coil is rinsed and dried to prevent any residual moisture from causing corrosion. Once cleaned, the steel coil can undergo various treatments depending on its intended use. One common treatment is pickling, which involves immersing the coil in an acidic solution to remove impurities and scale. This process helps to improve the surface finish and prepares the steel for further processing. After pickling, the coil may be subjected to cold rolling, a process that reduces its thickness and improves its dimensional accuracy. Cold rolling involves passing the steel through a series of rollers at room temperature, gradually reducing its thickness and increasing its strength. This process also improves the surface finish of the steel coil. In some cases, the steel coil may undergo additional heat treatment processes, such as annealing or tempering. Annealing involves heating the coil to a specific temperature and then slowly cooling it, which helps to relieve internal stresses and improve its mechanical properties. Tempering, on the other hand, involves reheating the coil to a lower temperature and then cooling it rapidly. This process enhances the strength and toughness of the steel. Once the desired processing and treatments are complete, the steel coil may be coated or painted to provide additional protection against corrosion or to enhance its aesthetic appearance. Coating processes can include hot-dip galvanizing, electroplating, or applying organic coatings such as paint or powder coatings. Finally, the processed and treated steel coils are typically cut into specific sizes or shapes based on customer requirements. This can be done using various cutting methods such as shearing, slitting, or sawing. Overall, the processing and treatment of steel coils involve a combination of cleaning, pickling, rolling, heat treatment, coating, and cutting processes. These steps are carefully carried out to ensure the quality, strength, and suitability of the steel for its intended applications.

- Q: What are the common coil thicknesses available for steel coils?

- The available thicknesses for steel coils, which are commonly used in different industries and applications, can vary depending on specific requirements. The range of coil thicknesses for steel typically falls between 0.5mm and 3mm. In lightweight applications or situations where flexibility is necessary, thinner steel coils with thicknesses ranging from 0.5mm to 1.5mm are often preferred. These thinner coils find suitability in automotive body panels, roofing, and general sheet metal fabrication. On the other hand, for applications that demand higher strength and durability, thicker steel coils with thicknesses ranging from 1.5mm to 3mm are frequently employed. These thicker coils are commonly seen in heavy-duty construction, structural components, and industrial equipment manufacturing. It is important to keep in mind that these mentioned ranges are general and can be subject to variation depending on specific project requirements or customer preferences. Steel coil thicknesses can be tailored to meet specific needs, providing greater flexibility across various industries.

- Q: Can steel coils be bent or shaped?

- Yes, steel coils can be bent or shaped. Steel coils are highly flexible and can undergo various bending and shaping processes to achieve desired forms and configurations.

- Q: I plan to buy a bushcraft knife ..The blade made up by damascus steel.My question is ,is damascus steel is very strong ?

- So, there isn't a good answer to your question, because Damascus doesn't describe the actual materials properties of the steel, rather the mechanical construct of the steel. For example: A very common Damascus steel is to layer L6 with 1080 high carbon steel and forge weld the layers together to make a blank, anneal it, then grind it into your blade and heat treat it. (Massive over simplification) That type of Damascus steel is going to be a bit softer than one of the super high carbon exotics, but will be tougher in terms of ability to flex without taking a set, and not chipping out if the edge hits something hard. (assuming it is heat treated well) - edge between RC56 - 58 typically. Another common Damascus steel is layers of VG-10 steel and VG-1 steel also welded together, with the billet then annealed, ground, and heat treated. In this case, because you are using stainless steels you will get a much harder edge - RC 60 - 62 typically. It will have better toughness than plain VG-10, but certainly nowhere near what you can get out of L6 or 52100 or something of that sort. Generally, for a bushcraft knife you typically want something like the first type of Damascus because you are looking for a more all purpose tool, and typically a larger knife. The only problem is that in the bush the first types of steel typically rust. The second type is made up of stain resistant steels and will hold up better. So, this brings me around to - why exactly do you want a Damascus blade on your knife? Are you already looking at one you like? Thinkingblade

- Q: How are steel coils used in the production of storage systems?

- Steel coils are used in the production of storage systems by being formed into sheets or strips, which are then shaped and welded to create the framework and shelves of the storage units. The high strength and durability of steel make it an ideal material for supporting heavy loads and ensuring the longevity of storage systems.

- Q: How do steel coils contribute to sound insulation in buildings?

- Steel coils contribute to sound insulation in buildings by absorbing and dampening sound vibrations. The dense and heavy nature of steel helps to reduce the transmission of sound waves, preventing them from traveling through walls and floors. Additionally, steel coils can be used as a core material in soundproofing panels, enhancing their effectiveness in reducing noise transmission.

- Q: How are steel coils coated to prevent rust and corrosion?

- Steel coils are coated to prevent rust and corrosion through a process called galvanization, wherein a layer of zinc is applied to the surface. This zinc layer acts as a sacrificial barrier, protecting the steel from exposure to moisture and oxygen, thereby preventing rust and corrosion.

- Q: Hi, I need to know why stainless steel is rust proof please tell me its for my science project. :)

- Why doesn't stainless steel rust? Nancy Avery, New London, Conn. Metallurgical engineer Michael L. Free of the University of Utah offers this explanation: Stainless steel remains stainless, or does not rust, because of the interaction between its alloying elements and the environment. Stainless steel contains iron, chromium, manganese, silicon, carbon and, in many cases, significant amounts of nickel and molybdenum. These elements react with oxygen from water and air to form a very thin, stable film that consists of such corrosion products as metal oxides and hydroxides.

Send your message to us

Pre-painted Aluzinc Steel Coils with Best Quality Competitive Price in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords