Pre-Painted Galvanized/Aluzinc Steel Coil--Chinese Best in Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

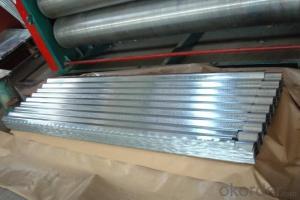

1. Pre-Painted Galvanized/Aluzinc Steel Coil--Chinese Best in Low Price

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features :

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• High strength

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

The Standard: AISI, ASTM, BS, DIN, GB, JIS

The Grade: DX51D, DX52D

The Thickness: 0.17-2.0mm

The Special Use: High-strength Steel Plate

The Width: 20-1250mm

The Length: customized

The Thickness: 0.13-4.0mm

The width: 20-1250mm

The zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

The color: all RAL color

The surface treatment: color coated

The coil weight: 4-7 tons

The coil ID: 508/610mm

The packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. How to guarantee the quality ?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of industrial compressors?

- Steel coils are used in the manufacturing of industrial compressors primarily for the construction of the compressor's casing and frame. The steel coils are shaped, cut, and welded to create the sturdy and durable structure that houses the compressor components. Additionally, the steel coils may also be used in the fabrication of other parts such as motor mounts or brackets, contributing to the overall reliability and stability of the compressor.

- Q: How are steel coils used in the manufacturing of engine mounts?

- Steel coils are commonly used in the manufacturing of engine mounts to provide durability, strength, and flexibility. These coils are typically designed to absorb and dampen vibrations, shocks, and movements generated by the engine during its operation. By integrating steel coils into the engine mount design, manufacturers can ensure better stability, improved performance, and reduced noise levels in vehicles.

- Q: How are steel coils used in the production of roofing systems?

- Steel coils are used in the production of roofing systems as they are formed into sheets or panels that are then shaped, cut, and fastened to create durable and weather-resistant roofs. The coils provide the raw material for manufacturing various components of the roofing system, such as metal tiles, standing seam panels, or corrugated sheets, which offer excellent strength, longevity, and protection against harsh elements.

- Q: I'm writing a book, and there is a part where there is a death arena with a white-hot river of steel. How hot would that be?

- White-hot steel is ~1200? C (2190 ?F) and above, though the exact temperature depends on the steel alloy used. To give you an idea of how hot this is: 5500? C surface temperature of the sun 1536? C Melting point of iron 1063? C Melting point of gold 660? C Melting point of aluminum 427? C Surface temperature of the sunward face of the planet Mercury 290? C Temperature of a commercial oven broiler

- Q: Several reading methods of steel tape measure

- Indirect reading methodIn some parts of the steel tape can not be used directly, can use the ruler or ruler, the zero alignment measurement, ruler and measurement direction; steel tape measure distance to a whole scale ruler or ruler, with more than a long reading amount. (3).Some errors in measuring steel tape

- Q: Can steel coils be used in the production of consumer goods?

- Consumer goods can indeed be produced using steel coils. In multiple industries, including automotive, construction, and manufacturing, steel coils are commonly employed as raw materials. Within the consumer goods sector specifically, steel coils can be utilized to manufacture a diverse array of items, spanning from appliances, furniture, and tools to packaging materials and even consumer electronics. The innate strength, durability, and adaptability of steel render it an optimal choice for fabricating consumer goods that necessitate stability, safety, and longevity. Furthermore, steel coils can be easily manipulated, molded, and shaped into distinct components or parts, enabling customization and design flexibility throughout the production process. Consequently, steel coils play an indispensable role in consumer goods production and find widespread use across various industries.

- Q: What are the different types of steel coil transport methods?

- There are several different types of steel coil transport methods, including flatbed trucks, specialized coil trailers, rail transport, and shipping containers.

- Q: Where are the coils and the steel plates used? Where did the steel plate come from?

- The use of steel coils, refrigerators, washing machines, household appliances, and other industries, parcels are winding.Steel plates can also be found everywhere: airplanes, guns, trains, ships, space shuttles, spaceships, automobiles, etc..Steel plate through mining - sintering - iron smelting - smelting - forming.

- Q: What are the weight ranges of steel coils?

- The weight ranges of steel coils can vary depending on their dimensions and intended use. Generally, steel coils can range from a few hundred pounds to several tons in weight. For example, hot-rolled steel coils typically weigh between 10 and 25 tons, while cold-rolled steel coils can weigh anywhere from a few hundred pounds to 20 tons. The weight of steel coils can also vary based on factors such as the thickness and width of the coil, as well as the grade and type of steel being used. Ultimately, the weight range of steel coils is determined by the specific requirements of the industry and application in which they are being used.

- Q: What are the common uses of cold rolled steel coils?

- Cold rolled steel coils have a wide range of common uses such as in automotive manufacturing, construction, appliances, furniture, and general engineering applications.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil--Chinese Best in Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords