Pre-painted Aluzinc Steel Coils / Color Coated Galvanized Steels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Usage of Galvanized steel coil:

Galvanized steel coil can also be welded and seamed, so it can be used for different tank fabrications that don’t involve corrosive materials. The uses for steel in coil stock form are numerous and expansive, because of the manipulability of the material and its natural resistance to the elements that other types of steel or metal aren’t able to withstand.

2.Applications of Galvanized steel coil:

construction | workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door |

door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter | |

Electrical appliance | refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker |

Furniture | central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf |

Carrying trade | exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board |

3.Details of Color Coated Galvanized Steel Coils:

NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC |

CERTIFICATE | ISO9001:2008 | ||

STANDARD

| EN10142 JIS G3302 GB/T-12754-2006 | ASTM A653 JIS G3302 SGCC/SGCH GB/T2518 European Standard | ASTM A792 JIS G3321 JIS G3317

|

GRADE

| CGCC CGCH CGCD1-CGCD3 CGC340-CGC570 GRADE

| SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R |

Mode No of prepainted steel coil | 0.16MM-1.5MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

Type of prepainted steel coil

| Steel coil Steel sheets/plates Corrugated steel sheets/plates

| Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates

|

Technique of prepainted steel coil | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled - galvanized | Hot rolled-cold rolled -galvalume /Aluzinc

|

Surface treatment of prepainted steel coil | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating

| |

Application of prepainted steel coil | Structural use ,roofing, commercial use, household appliance, industry, family | ||

SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | ||

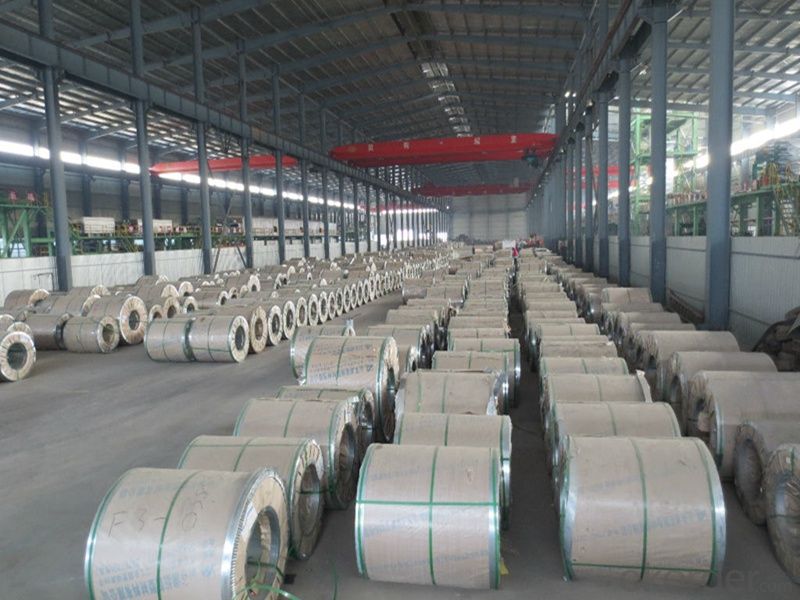

4. Color Coated Galvanized Steel Coils image:

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can you reload spent casings if they are steel?

- Technically they are reloadable but it's way too much effort and it'll probably cost more to do than its worth. I know you're probably asking this for surp. 7.62x54r right? The steel will have to be fully resized every time and you should only do it 1-2 time max to be safe. Also if your ammo is berdan primed the primers are very hard to find and these are a whole different beast than boxer primed. Short answer is yes but not worth it IMO.

- Q: I recently got in a car accident with a steel mailbox, on a snowy day. I was wondering if i can do anything since the steel mailbox caused my car to be totaled. Otherwise it would have been fine and would have suffered only minor damage. Anything I can do here to maybe get some money back? Thanks!

- The steel mailbox caused my car to be totaled? How did it do that? Did the mail box fail to stop at the stop sign? Did it rear end you when you stopped at the red light? Was the mail box under the influence of drugs or alcohol at the time of the accident? Or, would a more accurate way of putting it is you failed to take weather conditions into account and totaled your car by hitting a mail box? Stop blaming the innocent mail box.

- Q: How many types of steel buildings are there?

- There are a number of designs which can be used to create different types of steel buildings as per the demands of the buyer or an investor. he various kinds of that can be constructed using steel are Homes, Hangars, Agriculture and Farm buildings for storage, Garages and Storage sheds, Open air sheds,, Barns, Arenas and stadiums, Automotive buildings with overhead doors and flexible framed openings, Religious buildings such as Churches and Temples, etc.

- Q: What is the role of steel coils in the supply chain?

- Steel coils play a crucial role in the supply chain, particularly in the manufacturing and construction industries. These coils, which are typically made from hot-rolled steel, serve as a primary raw material for a wide range of products, including automobiles, appliances, construction materials, and various other industrial goods. The supply chain for steel coils begins with the production of raw steel, which is then processed and shaped into coils at steel mills. These coils are subsequently transported to various manufacturing facilities where they are transformed into finished products. Throughout this process, steel coils act as an intermediary product that is easily transportable, stackable, and can be easily manipulated to fit different manufacturing requirements. One of the key advantages of using steel coils in the supply chain is their strength and durability. Steel is known for its high tensile strength, which enables it to withstand significant loads and pressures. This makes steel coils ideal for applications that require robust materials, such as structural components in buildings, heavy machinery, and vehicles. Moreover, steel coils are highly customizable, allowing manufacturers to tailor the dimensions and specifications of the coils to meet their specific needs. This flexibility ensures that the supply chain can efficiently deliver steel coils that align with the requirements of different industries and projects. In terms of logistics, steel coils are typically transported in large quantities using specialized equipment such as flatbed trucks, railcars, or even ships. Efficient logistics planning is essential to ensure on-time delivery and minimize transportation costs. Additionally, proper storage and handling are crucial to prevent damage to the coils during transit and storage. Overall, steel coils play an integral role in the supply chain by serving as a versatile raw material that can be shaped and transformed into various end products. Their strength, durability, and flexibility make them a vital component in industries that rely on high-quality steel, ultimately contributing to the overall economic growth and development of numerous sectors.

- Q: If you keep it dry and clean, what steel will last the longest over the years with continued use and sharpening?

- you eventually will wear the blade out. i have seen old guys pocketknives that they used for whittlin and the blades have deep curves in them like khukris from wear. i reccommend, 440 stainless, or something with a rockwell hardness rating above 45.

- Q: What are the different types of steel coil cutting blades?

- Various types of steel coil cutting blades exist, each specifically designed for particular cutting purposes. 1. Slitting Blades: These blades are utilized to cut steel coils into narrow strips. They possess a straight cutting edge and come in different widths to accommodate various slitting needs. Industries like automotive, construction, and metal fabrication commonly employ these blades. 2. Shearing Blades: These blades are created to cut steel coils into flat sheets. They feature a curved cutting edge that enables a clean and precise cut. Steel service centers, where large coils are transformed into flat sheets for further manufacturing processes, frequently utilize shearing blades. 3. Circular Blades: Also known as rotary blades, these blades are employed for continuous cutting of steel coils. With a circular shape adorned with sharp teeth along the edge, they can effectively cut through the coil as it passes through the cutting machine. Industries such as packaging, printing, and paper manufacturing often make use of circular blades. 4. Guillotine Blades: These blades are employed to cut steel coils in a straight downward motion. Possessing a vertically moving straight cutting edge, they can effectively slice through the coil. Guillotine blades are frequently used in heavy-duty cutting applications that involve thick steel coils or large quantities of material. 5. Slitter Knives: Similar to slitting blades, slitter knives are typically smaller and employed in slitting machines that require multiple blades. Industries requiring high-precision slitting, such as electrical transformer production or precision metal stamping, often rely on slitter knives. Each type of steel coil cutting blade possesses unique characteristics and designs that render them suitable for specific cutting tasks. The appropriate blade selection depends on factors like steel coil thickness and width, desired cut quality, and specific application requirements.

- Q: How are steel coils used in the manufacturing of flooring materials?

- Steel coils are used in the manufacturing of flooring materials as they provide strength and durability to the flooring. The steel coils are often used as a base material for various types of flooring, such as vinyl, laminate, or engineered wood. These coils are processed and shaped into sheets or panels, providing a stable and sturdy foundation for the flooring materials. Additionally, the steel coils are also used for reinforcing concrete flooring, adding extra strength and preventing cracks or damage.

- Q: i mean the properties include the elasticity, impact load and ductility. am doing assignment about the perfect material that should be possessed by spring and i found alloy steel is the perfect and am confused whether stainless steel is the same with alloy steel ?

- *Alloy steel is not same as stainless steel. An alloy steel is not the perfect spring steel. Since you are doing the project, please understand the carbon steel,alloy steel and super alloys. Alloy steel is steel alloyed with a variety of elements in amounts of between 1 and 50% by weight to improve its mechanical properties. Alloy steels are broken down into two groups: low alloy steels and high alloy steels. Stainless steel is a type of high alloy steel. *As far as spring material is concern , spring steel or music wire is best suited. Spring steel is a low alloy, medium carbon steel or high carbon steel with a very high yield strength. This allows objects made of spring steel to return to their original shape despite significant bending or twisting. Silicon is the key component to most spring steel alloys. An example of a spring steel used for cars would be AISI 9255 (DIN and UNI: 55Si7, AFNOR 55S7), containing 1.50%-1.80% silicon, 0.70%-1.00% manganese and 0.52%-0.60% carbon. Most spring steels (as used in cars) are hardened and tempered to about 45 Rockwell C. Since sufficient links were given earlier but I like you to go through spring steel as it is your subject matter. I have done the project on The design of a helical compression spring selected material was ASTM A228 (0.80–0.95% carbon).

- Q: Does anyone know what colour steel is?How hard steel is?The density of steel?Conductivity of steel? (Heat and electricity)Reactivity of steel?Melting and boiling points of steel?And the malleability and ductility of steel?Ive looked all over the net and i cant find anything. Can someone please answer these questions or give me a website?THANKS!

- It is usually a grey color, more silver when freshly scratched. Every one of the other questions can range based on the quality of the steel and other variables such as thickness. That's more than likely the reason you couldn't find any info on it. Its hardness is based on quality, for example regular steel is softer than Mild steel. It can be a thin sheet or a thick plate (which could then be changed to a tube Circle or square) etc

- Q: any one have an opinion? i've heard steel cut oatmeal is better for you...

- Old fashioned is the whole oat - the steel cut is oats all cut up. The steel cut is more mushy when prepared while the old fashioned has that good thick texture and feel to it.

Send your message to us

Pre-painted Aluzinc Steel Coils / Color Coated Galvanized Steels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords