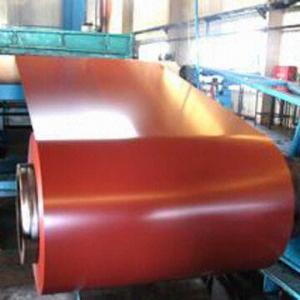

Pre-Painted Aluminum Coils Price, Roll

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (asmuch as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Features:

1. Excellent quality of products

2. Quick delivery

3. Best service to clients

4. BV,SGS avalible

5. No buckle o waveness

6. Tension leveling

7. Certificate of Origin

8. Form A,E

Packaging Detail: Carton ,Wooden pallet with plastic protection packing,standard seaworthy packing or as your request.

ProductionCapacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Coveredfactories with full production line

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

30 day after client’s deposit

- Q: What are the potential applications of coil-embossed aluminum coils?

- Some potential applications of coil-embossed aluminum coils include building and construction materials, such as roofing and siding, as well as decorative elements for interior design. Additionally, these coils can be used in the manufacturing of appliances, automotive parts, and packaging materials, due to their durability, aesthetics, and corrosion resistance.

- Q: Can aluminum coils be customized to specific requirements?

- Yes, aluminum coils can be customized to specific requirements. The customization process involves adjusting the dimensions, thickness, alloy composition, and surface finish of the coils to meet the specific needs of different industries and applications.

- Q: Is it possible to create a mobile phone stand or holder using aluminum coils?

- <p>Yes, you can use aluminum coils to make a mobile phone stand or holder. Aluminum is lightweight, durable, and easy to shape, making it a suitable material for such DIY projects. You can bend the aluminum coil into the desired shape to support your phone, either horizontally or vertically. Ensure the coil's diameter is appropriate to hold your phone securely without causing any damage. Remember to smooth any rough edges to prevent scratches on your phone.</p>

- Q: How are aluminum coils used in the production of musical instruments?

- Aluminum coils are commonly used in the production of musical instruments, particularly in wind instruments like saxophones and trumpets. These coils are shaped into a specific design and attached to the instrument to create the desired sound. The aluminum material allows for a lightweight and durable construction, enhancing the instrument's playability and resonance.

- Q: Are aluminum coils suitable for electrical insulation?

- No, aluminum coils are not suitable for electrical insulation. Aluminum is a good conductor of electricity, meaning it allows the flow of electric current rather than resisting it. In electrical systems, insulation is needed to prevent the flow of electricity and protect against short circuits or electrical shock. Materials such as rubber, plastic, or ceramic are commonly used for electrical insulation due to their high resistance to electric current.

- Q: Are there any restrictions on the coil thickness of aluminum coils?

- Yes, there are certain restrictions on the coil thickness of aluminum coils. The thickness of aluminum coils may vary depending on the specific application and manufacturing process. However, it is generally limited by practical constraints such as the equipment capabilities, handling and transportation considerations, and the desired properties of the final product.

- Q: Can aluminum coils be embossed or textured?

- Yes, aluminum coils can be embossed or textured. Embossing or texturing involves the process of creating patterns or designs on the surface of the aluminum coil. This can be done through various methods such as mechanical or chemical processes. The embossed or textured surface adds aesthetic appeal and can also improve the functionality of the aluminum coil, such as enhancing its grip or reducing glare. These embossed or textured aluminum coils find applications in various industries such as construction, automotive, and packaging.

- Q: What are the common surface treatments for aluminum coils in the marine industry?

- In the marine industry, aluminum coils are commonly subjected to various surface treatments to enhance their durability and resistance to corrosion. Some of the most common surface treatments for aluminum coils in the marine industry include anodizing, powder coating, and chemical conversion coatings. Anodizing is a popular surface treatment method that involves the formation of a protective oxide layer on the aluminum surface through an electrolytic process. This oxide layer not only enhances the corrosion resistance of the aluminum coil but also provides it with improved abrasion resistance and an attractive appearance. Anodizing can be done in various colors, allowing for customization and aesthetic appeal. Powder coating is another widely used surface treatment for aluminum coils in the marine industry. It involves applying a dry powder to the aluminum surface, which is then cured under heat to create a durable and protective layer. Powder coating provides excellent resistance to UV rays, chemicals, and abrasion, making it a favorable choice for marine applications where exposure to harsh environmental conditions is common. Chemical conversion coatings are also commonly applied to aluminum coils in the marine industry. These coatings are formed through a chemical reaction between the aluminum surface and a solution containing specific chemicals. The resulting coating provides excellent corrosion resistance and acts as a barrier against moisture and other environmental factors. Chemical conversion coatings are often used as a pre-treatment before applying other coating systems to further enhance the aluminum coil's protective properties. Overall, the choice of surface treatment for aluminum coils in the marine industry depends on factors such as the intended application, environmental conditions, and desired aesthetics. Anodizing, powder coating, and chemical conversion coatings are among the most common options, each offering unique benefits to ensure the longevity and performance of aluminum coils in marine environments.

- Q: What are the different coil handling equipment options for aluminum coils?

- Some different coil handling equipment options for aluminum coils include coil lifters, coil tilters, coil cars, and coil upenders. These equipment options are designed to safely handle and transport aluminum coils in various industrial applications.

- Q: What are the typical lead times for aluminum coil orders?

- The typical lead times for aluminum coil orders can vary depending on several factors. Generally, lead times for standard aluminum coil orders range from a few weeks to a few months. These lead times are influenced by factors such as the size and complexity of the order, the availability of raw materials, the production capacity of the supplier, and any specific customization requirements. It is important to note that lead times may be longer for larger or more specialized orders, especially if they require additional processing or finishing. Additionally, external factors such as transportation and logistics can also impact lead times. It is always recommended to communicate with the supplier directly to get an accurate estimate of the lead time for a specific aluminum coil order.

Send your message to us

Pre-Painted Aluminum Coils Price, Roll

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords