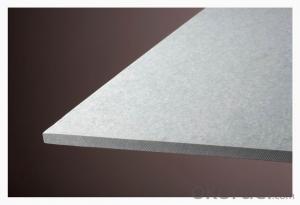

Pre-galvanized steelbearing plate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000Tons m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fire and bearing, can provide 4 hours of refractory time limit and bearing load of 10Kpa.

Application: civilian reconstruction project (hotels, hotels, shopping malls, office building, workshop transformation) and the new project (slab, steel structure project of offshore drilling platform, hull load-bearing deck) etc..

Its characteristics: Fire 4 hours bearing 10Kpa; can be placed in the load-bearing floor on electromechanical equipment group;

Provide the personnel operating platform; instead of traditional steel plate concrete floor, floor, installation fast, no need of maintenance

| Effective width | Wall panel: 950mm 1150mm Roof panel: 960mm |

| Length | According to customer's request |

| Materials | Rock wool, Color steel sheet |

| Structure | Upper and lower layer: Color steel sheet |

| Middle: Rock wool | |

| Thickness | Color steel sheet: 0.3-0.6mm Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm |

| The rock wool density | 110kg/m3 120kg/m3 |

| Conventional color | Ocean blue, whitegrey, etc |

| Character | Fireproof, heat insulation, green and environmental |

| Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

- Q: I see the tutorial, in Altium, click the design under the layer stack manager, pop-up layer stack manager, double-click the top layer or core or bottom layer can set some parameters, those parameters can not be set?

- Do not set up, with TXT document, named readme can be. Another copper thickness is generally 35um instead of 0.35.

- Q: How to install the wall rock wool sandwich panels

- 1, handling the plate should also be lifted at both ends, so as not to damage the appearance of oxide film or coating. When installing the wall panel, only one board can be lifted at one time. It should be used for the special fixture supplied by the manufacturer of the rock wool sandwich panel. Lifting process to slow down, to use the wind rope to be controlled to prevent the wall with the device has been bump, scaffolding raised parts with soft data package. 2, sandwich plate fixation method: one is the self-tapping screw through the wall directly to the wall in the secondary structure. Another method is the self-tapping screw connected directly to the wall sub-structure via the coupling.

- Q: What kind of PCB need to use Anti-CAF sheet

- Anti-CAF is a material with special characteristics! In fact, the ordinary FR4 sheet also has enough of this feature, but in the special areas of the product may require more stringent reliability, so the material supplier was the introduction of such a special plate! Electronic migration is mainly a greater impact on the environment, such as humid environment will exacerbate the risk of electronic migration! From the product structure, such as the spacing between the holes is too small, will also cause greater risk!

- Q: What conditions do you need? The The Its general 2-story cost is? The The Size needs to be the kind of foreign people to live !!! in Xi'an where to facilitate the purchase of materials? The The I need professional answers!

- (A) Advantages: First, the wooden structure of the construction period is short, the cost of small risk. Second, the construction of wood structure houses consume far less energy than other structural houses. Such as the construction process, the steel wall of the energy consumption of bone columns than the wooden wall of the energy consumption of 3.2 times higher. Wood structure construction of energy-saving features will be fully reflected in the developer's investment cost returns. Third, because the wood structure used in the structural parts and connectors are standardized production, reducing the operating intensity, the labor required for construction will be greatly reduced. Therefore, the wood structure can also save the cost of labor for developers. Fourth, the wooden structure of housing is environmentally friendly high-end residential, timber according to different architectural shapes through the modern technology production and processing into a different wall profiles, and then after the flame retardant, anti-corrosion processes and other processes, more durable. Against sinking stress, anti-dry, anti-aging, with significant stability. Fifth, the wooden structure of housing is not only high quality and timely service, a strong selling point for developers. Sixth, the wooden structure of the villa is different from the brick and concrete structure is another important aspect of it in many areas have strict international standards, on-site assembly is also often a professional team, the accuracy of the product for the construction of the accuracy provided a prerequisite. Due to the quality of the wooden structure of residential quality have full confidence, the general professional companies in the main equipment can do 5 years warranty, brick and concrete structure of the general warranty of not more than 3 years.

- Q: Is there a requirement for the density of the steel wall

- Why choose foam sandwich panels? Know the European rock wool color plate it? European rock wool color steel plate is the steel structure of the system of energy-saving composite materials, with two high-quality color coated steel plate after forming as a panel, the use of high-quality rock wool fiber turned 90 ° after the core material Fiber and steel plate into a vertical shape), through the high strength, high viscosity of the two-component adhesive, high-quality basalt cotton and color steel plate bonding, the double-track heating and heating from the new high-end building materials The

- Q: E0 grade sheet and E1 grade plate, which is more environmentally friendly? How to distinguish

- E0 level is the European standard, e1 level is the domestic standard, e0 relatively strict implementation of the standard, which is commonly referred to as more environmentally friendly, but the so-called business e0 level is sometimes just a rhetoric, the best time to buy Look at the relevant files. Can not let its flicker.

- Q: Hi Guys,I am just about to purchase these rawl plugs on OKorder.Do you think these will hold some heavy items like shelves, curtains etc.

- but I've always just used the heavier duty ones to be on the safe side. The plugs you have highlighted have little by means of retention except for the actual screw - there is nothing to stop it ripping out of the plasterboard under heavy strain.

- Q: can i put 8ft by 4ft plasterboards on a ceiling?

- Yes. You should rent a sheetrock jack for doing ceilings, it will make the job much easier. Tape & mud Then textuerd ceiling paint or have popcorn texture sprayed on.

- Q: I recently had my bathroom refurbished and the installer put new plasterboard on the ceiling. I thought he would have skimmed it with some plaster but he tells me that they don't do that now and you can paint direct onto the plasterboard. As the outer coat of plasterboard seems to be a type of paper I am a bit worried about painting direct onto the plasterboard. Any views, hints etc.

- Yes you can just remember to put Polly Filler on the nails and then you can put your undercoat on,then your final coat prefrably vynil

- Q: What is cold rolled plate ah? Cold rolled plate is a plate of no

- Cold rolled coil is hot rolled coil as raw material, at room temperature in the recrystallization temperature of the following rolling, including the board and volume, many domestic steel mills such as Baosteel, China Iron and Steel, Anshan Iron and Steel can produce.

Send your message to us

Pre-galvanized steelbearing plate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000Tons m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords