pre- galvanized steel perforated cable tray

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Anhui China (Mainland) | Brand Name: | YF | Model Number: | YF |

| Type: | Ventilated or Perforated Trough | Material: | Steel | Width: | 150-1000MM |

| Length: | Customized | Side Rail Height: | 65-200MM | Classification: | ventilated cable tray |

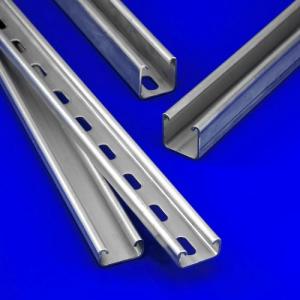

| Component: | Support, support arm and accessories and fittings | Surface treatment: | Electronic galvanized, hot dip galvanized, painted | Application: | petrochemical, metallurgy, electric power |

| Standard package: | Plastic Film inside and Steel frame outside |

Packaging & Delivery

| Packaging Detail: | Standard package:Plastic Film inside and Steel frame outside |

| Delivery Detail: | Within 20 to 25days |

Specifications

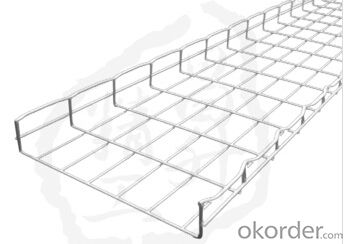

Ventilated raceway for cables

1.Simple structure

2.beautiful appearance

3.flexible configuration

4.convenient maintenance.

Simple Structure Hot Dipped Galvanized Wireway

Cable tray

Cable tray is the carrier which is to support and protect all kinds of cable laying cable.

Cable tray classification

Non-ventilated cable tray, ventilated cable tray, ladder cable tray, wire mesh cable tray

The material of cable tray

St03z galvanized steel, Q235 steel plate, aluminum alloy, glass fiber reinforced plastic

Cable tray component

Support, support arm and accessories and fittings

Cable tray surface treatment

Electronic galvanized, hot dip galvanized, electrostatic spraying, prevent fire coater materials, painted

Cable tray advantages

Simple structure, beautiful appearance, flexible configuration and convenient maintenance.

Cable tray application

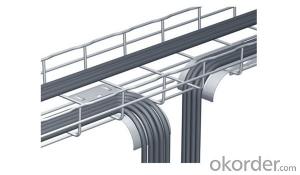

Which products are widely used in petrochemical, metallurgy, electric power, the school of communication, high-rise building, etc

The selection of cable tray and recommendations:

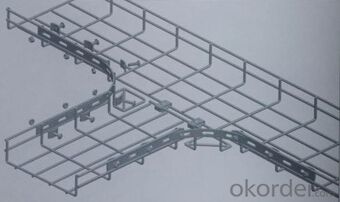

1. Can independently set up within the building bridge, can also be attached at the various buildings and on the pipe gallery

2. The installation outside the building, if it is in near the sea or belong to the corrosion area, which must have the anti-corrosion material, moisture resistance, good adhesion, impact resistance properties of high strength characteristics.

- Q: What is the minimum distance between the lighting cable bridge and the weak bridge construction?

- Its open structure not only allows the cable to maximize the ventilation and heat, save energy, optimize the cable performance, but also to prevent water, dust, debris of the child for the good wheat field mad mad sickle accumulation, bacteria is not easy to breed , More clean, reduce the risk of fire or other safety hazards These unique features bring surprises to Chinese customers 90% open space; high mechanical strength, easy to cut; can give full play to your imagination free configuration style; no screw nut; for the data cable The design of the annex; with a compelling carrying capacity; save space and time for customers than the traditional bridge to save 1/3 of the installation time; unique bending method, fast, beautiful; 1000 degrees Celsius high temperature can also be maintained for 90 minutes, Protection of the safety of the bridge, is the most certified bridge and so on If you need the most professional support, you can contact me wwwvichnetcom this online introduction of this product is very

- Q: Such as: 200 * 100 * 1.5. Ordinary, galvanized and hot galvanized. How is the price calculated? Is there a formula? More

- First have to admit that your TV is more powerful, ha ha! So many sound input, but compared to the next two pictures is not difficult to know, in fact, are different input interface! Yellow insert ANT input, which is the middle of the yellow like! Red and white points were inserted into the audio input 1-2 like! The rest are corresponding to the color difference, S-video audio input lost in the mouth of the fabric of the mouth of the mouth, if you find no sound, please correspond to the audio input ...5!

- Q: What is the meaning of the separation within the cable tray?

- Negative pole connected to the body and the engine ground, the pole is connected to the motor starting horse, and all electrical equipment, hoping to help you! The The [Car problem, ask the car master. 4S shop professional technician, 10 minutes to solve. To

- Q: Our drawings are messy, some cableway or walk the bridge it also wear steel pipe, I would like to have this need to explain, we this project is the highest 23 layers more

- It is to be installed and Ming Tu, not concealed and dark laying.

- Q: What is the profit of the cable tray?

- Automotive connector four basic structural components First, the contact, is the car connector to complete the electrical connection function of the core parts

- Q: The bridge has a combination of cascade, tray, grid, slot, etc., which in turn with the trough bridge and metal trunking is most similar. And the project cost in the trough and the bridge of the unit price difference of dozens of pieces of one meter, so it is very important to distinguish them ... ... Now a construction team with 200 * 100 slot cable, and some of the floor of the feeder 200 * 100 of the groove with 100 * 50 slot laying. The material of the groove looks like stainless steel, there is no corresponding turn accessories (the term how to call?) Cable or branch line at right angles, between the two slots are not connected to the corresponding hole, the upper and lower cover seal. I ask the money when the "slot" is the price of the bridge to the metal trunking or to the money? More

- The bridge is used to lay the power cable and control cable, the trunking is laying wire and communication cable; bridge is relatively large (200x100 to 600x200), the trunking is relatively small; bridge bending radius is relatively large, ; Bridge span is relatively large, the trunking is relatively small; fixed, installation in different ways; in some places, the bridge is not covered, trunking is almost all covered with a lid. The trunking is used to track, the bridge is used to take the cable.

- Q: Does the weak and fire can share a cable tray?

- . cable tax classification code selection wire and cable. . tax classification code selection tax classification coding part of the code tax rate and the actual tax rate is not consistent with the accounting, you can call the tax classification code, and then "commodity code editor" interface and then modify the tax rate. need to open a mixed category of goods, such as supermarkets issued by the name of food products, but the actual product is bread, biscuits, milk and a series of goods collectively. Tax classification code for the division of the more detailed, so can not be called together with a number of coding, the proposed accounting in accordance with the actual product name and then select the appropriate tax classification code, or let the accounting advisory manager of the Inland Revenue Department is allowed to collectively, which should be selected category Instead of the choice of tax classification code, the first to determine whether the sale of goods, or service industry, which helps to find in the category. It is recommended to use the search search keywords (do not enter the full name). if the need to issue a commodity is collectively referred to, such as A unit issued by the goods is fixed assets, you can ask the next account of what is the specific fixed assets, vehicles, office use, the use of goods, part of the tax classification code may not be found in the lowest level menu directory, but in his upper level menu directory there is no need to find the tax classification code. For example: nursery this commodity. Point "forestry products" under the three subdirectories are not found, but click on "forestry products" will appear.

- Q: What are the accessories that are connected to the bridge and what are the names?

- The first is a low-smoke halogen-free cloth wire, single-core only insulation without sheath, and the latter is a low-smoke halogen-free power cable, insulation is cross-linked polyethylene, jacket is low smoke

- Q: What is the difference between a trough bridge and a tray tray?

- The steel pipe is easy to make the cable broken, and the steel is conductive. Really want to break the skin, increase the danger

- Q: Do not have a very professional, can mark the specific layout, specifications can be

- Transfer test Note: in the high-pressure test equipment and high voltage around the lead, should be installed to block and hang warning signs When conducting a high voltage test, the operator and the high voltage circuit should have sufficient safety distance after the end of the high-pressure test, the DC test equipment and large capacitance of the equipment to be tested multiple discharge, discharge time of at least 1min or more Where the absorption ratio of less than 12 of the motor, should first dry and then exchange pressure test circuit breaker AC voltage test should be in the sub-closing state were carried out separately In addition to the complete installation of the factory, the insulation equipment should be separated from each other to do DC voltage, the test voltage 05 times the rated voltage per stage increased in stages, each phase to stay 1min, and record the leakage current

Send your message to us

pre- galvanized steel perforated cable tray

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches