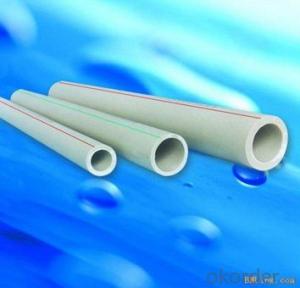

Plastic Tubes for Industrial and Agricultural PPR Pipes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Nowadays PPR pipes win more attention and have been used all over the whole world more widely with its excellent sanitization performance, high heat resistance, compression resistance, corrosion resistance, pliability and seismic performance which make PP-R the real environmental friendly pipe.

Product Feature:

1. High Temperature Resistance: the maximum sustained working temperature is up to 70°C , the maximum transient temperature is up to 95°C

2. Heat Preservation: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe

3. Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium

4. Corrosion Resistance: resist chemical matters and electron chemical corrosion

5.High Flow Capacity: smooth interior walls and low friction result in low flow resistance and high volume

6. Excellent Flexibility: can be supplied in coil

7. Low Installation Costs: light weight and ease of installation can reduce installation costs

8. Longevity: more than 50 years under proper use

9. Recycled and Environment-friendly

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

FAQ

Q: If the products have some quality problem ,how will you deal with it?

A: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind. Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q.How can I get a sample?

A: FREE SAMPLE can be sent to you .Freight will be collect

Q. Is free design assistance available for clients?

A: If you have problems in designing or beautifying the customized product, we will offer you the best design assistance.Pictures

Q:, Which factors can be customized?

A: Material, Color, Size, Packing ,Brand, delivery

Q; Advantages of your products?

A:Company products, good quality, high reputation guarantee.

- Q: Where do I find a metal magazine tube follower for a remington 1187?? All i can find are plastic!!!?

- Most new ones are plastic. Here is one.

- Q: Can plastic tubes be easily cleaned or sterilized?

- Yes, plastic tubes can be easily cleaned and sterilized. They can be washed with soap and water, and then sterilized using various methods such as autoclaving, chemical disinfection, or steam sterilization.

- Q: How are plastic tubes recycled?

- Plastic tubes are recycled through a process that involves sorting, cleaning, shredding, melting, and reforming. First, the tubes are sorted based on their plastic type and color. Then, any contaminants are removed through a thorough cleaning process. Next, the tubes are shredded into small pieces. These shredded pieces are then melted and formed into small pellets or granules. These pellets can be used to manufacture new plastic products, including tubes, or can be used as raw materials in various industries.

- Q: I have a little bit of a project. I'm trying to figure a way to cool a pair of water filled tubing lines. I was thinking to wrap it with some type of cooling device but not quite sure what to use. Can you guys give me some ideas? I want to cool the lines as cool as refrigerator temps. Thanks.

- You have not said how much heat you need to disperse - whether it needs to be a continuous process or not. You have not mentioned whether the lines are flexible or what length they are! However, without making things too complicated, if you use a longish length of plastic tubing, you could coil them and run them through a bucket full of an ice/salt/water mixture. Depending on how fast the water is moving through the tubes, if you had a strong mixture of salt and ice - with just enough water in the bucket to allow conduction - you might be able to freeze the water in the tubes - which is probably NOT what you want to do. So experiment before the performance.

- Q: where would be a good place to start looking? recycling places? arts and crafts? home depot? Im just looking for something rather cheap.

- Try PVC piping hard to find it in clear normally comes in white/grey but this am sure will do it you. Good luck

- Q: Something that can coil up.

- Any good hardware store. They have flexible plastic tubing displays in all different diameters.

- Q: Are plastic tubes resistant to impact or pressure?

- Plastic tubes can vary in their resistance to impact and pressure depending on the type of plastic used. Some plastics, such as PVC, HDPE, and PTFE, are generally more resistant to impact and pressure compared to others. However, the specific design, thickness, and manufacturing quality of the plastic tube also play a significant role in determining its resistance. It is advisable to consider the specific application requirements and consult with manufacturers or experts to ensure the appropriate plastic tube is selected for desired impact and pressure resistance.

- Q: What are the different shapes available for plastic tubes?

- There are a variety of shapes available for plastic tubes, including round, square, rectangular, oval, and triangular.

- Q: The antenna ripped off just under the Cap at the top of the antenna tube, will i expect any problems as far as the RC going out of control? Or should I just go out and get a new one?

- Better get it replaced. Don't try to run it with the proper length antenna. You won't have any range and the truck will go out of control.

- Q: Are plastic tubes suitable for industrial packaging?

- Yes, plastic tubes are suitable for industrial packaging. They are lightweight, durable, and offer excellent protection to the contents inside. Plastic tubes also provide flexibility in terms of size and shape, making them versatile for various industrial packaging needs. Additionally, they are cost-effective compared to other packaging materials and can be easily customized and labeled for branding purposes.

Send your message to us

Plastic Tubes for Industrial and Agricultural PPR Pipes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords