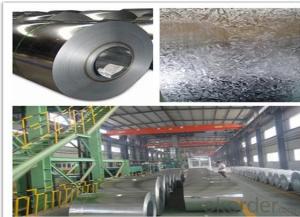

PPGI Prepainted Galvanized Steel Coils for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:DX51d SGCC DX52d

Surface Treatment:Coated

Certification:ISO, SGS

Technique:Hot Dipped

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Boiler Plate

Edge:Slit edge

Stock:Stock

Steel Grade:Dx51d

Thickness:0.3mm

Width:1250mm

Top Paint:15+5

Back Paint:5-7

ID:508mm

Coil Weight:3-8 Tons

Zinc Coating:50g-250g/Psm

Gloss:65%-80%

Feedback:Within 24 Hours

Export Markets:Global

Additional Info.

Packing:Export Standard Package

Standard:AISI, ASTM, BS, DIN, GB, JIS

Origin:Shandong

HS Code:7210701000

Production Capacity:150, 000tons/Year

Product Description

Specifications:

1. Thickness: 0.12mm-1.3mm

2. Width: 600mm-1250mm

3. Length: According to client's demands

4. Top paint: 15 to 25 um (5 um + 12-20 um)

Back paint: 7 +/- 2 um

5. Gloss: Normal or High gloss

6. Zinc coating: Z50-Z275G/psm

7. Inside Diameter: 508mm/610mm

8. Outside Diameter: 1000mm-1500mm

9. Coil weight: 3-8 tons

10. Payment: T/T, L/C, D/P, Paypal, Western Union

11. Trade Term: FOB, CFR, CIF

12. MOQ: 30 Mt

13. Package: Export standard package or as request

14. Shipment: By container

15. Standard: AISI, ASTM, BS, DIN, GB, JIS

16. Grade: JIS G3322, CGLCC, ASTM A755, CS-B

Why Us:

1. ISO, BV, CE, SGS approved

2. Competitive price and quality from our own factory

3. Efficient service team online for 24 hours

4. Smooth production ability(50000tons/month)

5. Quick delivery and standard exporting package

6. Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc

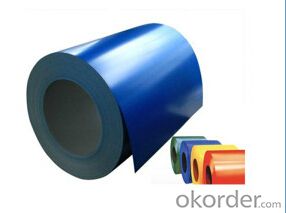

| Name | 0.3mm Thickness PPGI Prepainted Galvanized Steel Coil |

| Resin constructure Technique of production | Double painting and double baking process |

| Productivity | 150,000Tons/year |

| Thickness | 0.12-1.3mm |

| Width | 600-1250mm |

| Coil Weight | 3-8 Tons |

| Inside Diameter | 508mm Or 610mm |

| Outside Diameter | 1000mm-1500mm |

| Zinc Coating | Z50-Z275G/psm |

| Painting | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

| Standard | JIS G3322 CGLCC ASTM A755 CS-B |

| SurfSurface coating coloace coating type | PE, SMP, HDP, PVDF |

| Back side coatingcolor | Light grey, white and so on |

| Application | PPGI is featured with light-weight, good looking and anticorrosion. It can be processed directly, mainly used for construction industry, home electronic apparatus industry, electronic apparatus industry, furniture industry and transportation |

- Q: How do steel coils contribute to the manufacturing of agricultural machinery?

- The manufacturing of agricultural machinery heavily relies on steel coils, which play a vital role in this process. Typically, these coils are crafted from top-notch steel that possesses exceptional strength, durability, and resistance to corrosion. To begin with, agricultural machinery heavily relies on steel coils for the construction of its main structural components, including the chassis, frames, and supports. These components must endure heavy loads, extreme weather conditions, and rough terrains. Thanks to the strength and resilience of steel coils, the machinery can effectively handle these challenging environments and operate efficiently. In addition, steel coils find application in the production of various moving parts and mechanisms within agricultural machinery. For example, gears, shafts, and axles, which are crucial for power transmission and rotational motion transformation, are created using steel coils. The high tensile strength and excellent machinability of steel make it an ideal material for these essential components, ensuring their reliability and longevity. Moreover, steel coils contribute to the manufacturing of agricultural machinery by providing a protective layer against wear and tear. Often, these coils are coated with specialized finishes or paints to enhance their resistance to rust, chemicals, and abrasion. This protective layer significantly prolongs the machinery's lifespan, reduces the need for frequent maintenance and repairs, and ultimately increases its overall efficiency and productivity. Furthermore, the versatility of steel coils allows for customization and adaptation to meet the specific requirements of agricultural machinery. Manufacturers can shape and mold the coils into different sizes and dimensions, enabling the production of machinery suitable for various farming practices and applications. Whether it's tractors, harvesters, or irrigation systems, steel coils are crucial for creating versatile and dependable agricultural machinery. In conclusion, steel coils are essential in the manufacturing of agricultural machinery due to their strength, durability, resistance to corrosion, and customization capabilities. From structural components to moving parts and protective coatings, steel coils greatly contribute to the efficiency, reliability, and longevity of agricultural machinery, thus providing significant support to the global agricultural industry.

- Q: My daughter wants a pair of steel toe cap boots for around the horses but wants them warm, so ideally fur lined etc. Does anybody know where I could purchase them as everywhere I look its only one or the other, cant get steel with fur lining. Very frustrating. I live in the uk. Many thanks.

- TRY FINDING A GOOD PAIR OF WOOL SOCKS. MOST OUTDOOR STORES LIKE BIG 5, DICK'S OR BASS PRO SHOPS CARRIE A GREAT SELECTION OF WINTER STOCK.

- Q: How are steel coils used in the manufacturing of transportation equipment?

- Steel coils are used in the manufacturing of transportation equipment as they provide a durable and strong foundation for various components such as chassis, frames, and body panels. These coils are typically processed and shaped into specific forms to meet the design requirements of automobiles, ships, trains, and aircraft. The high tensile strength and ability to withstand heavy loads make steel coils an essential material in the transportation industry, ensuring the safety and reliability of the vehicles and equipment.

- Q: Can steel coils be coated with epoxy?

- Yes, steel coils can be coated with epoxy. Epoxy coatings are commonly used to protect steel from corrosion and provide a durable finish.

- Q: How are steel coils used in the production of HVAC systems?

- Steel coils are used in the production of HVAC systems as they serve as the primary component for heat transfer. These coils are responsible for absorbing heat from the surrounding air and transferring it to cool the interior of a building. Additionally, steel coils are used for the condenser coils in HVAC systems, where they aid in the removal of heat from the refrigerant, allowing for efficient cooling and dehumidification.

- Q: Can steel coils be cut or trimmed after delivery?

- Yes, steel coils can be cut or trimmed after delivery. This process is commonly known as slitting, where the steel coil is passed through a set of circular blades to create narrower strips of steel. Trimming can also be conducted to remove any unwanted edges or imperfections. Both cutting and trimming are common practices in the steel industry to meet specific size and shape requirements for various applications.

- Q: What are the common coil coating methods?

- The common coil coating methods include roll coating, spray coating, and coil coating with pre-painted metal substrates.

- Q: I am buying a knife for my future husband for his wedding gift and I was wondering what is better carbon steel or stainless steel?

- carbon steel is my choice. googlecarbon steel vs stainless steel knives for more info. If you buy stainless make sure it is an alloy that will hold an edge..many a shiny knife is just a dull dud. Carbon blades don't rust unless they are left laying in the wet. I was having this conversation with a Friend once. So I took his knife and struck his knifes edge against mine with a light blow.. His had a 1/16 dent in it, mine not even a mark on it. I assume this is not a kitchen knife.

- Q: Hi there! I just purchased two cookie sheets labeled as non-stick 100% carbon steel. I've never heard of carbon steel before, and I'm trying to be careful about not using certain products that are harmful to health such as aluminum and Teflon. Is this a safe metal choice for baking?

- This Site Might Help You. RE: Is 100% carbon steel baking sheet safe? Hi there! I just purchased two cookie sheets labeled as non-stick 100% carbon steel. I've never heard of carbon steel before, and I'm trying to be careful about not using certain products that are harmful to health such as aluminum and Teflon. Is this a safe metal choice for...

- Q: Can i make holes in iron and steel with somekind of drill bit. All i have is metal drill bits. Mabey like 68 of them but i dont know wich one to use and if they will penetrate.

- That's what drill bits are made for. Those for steel and iron will usually be made of high speed steel. What is important, is the sharpening, and of course, the overall condition of the drill bit. If you need to drill a larger hole, it is helpful to drill a small hole first (pilot drilling), then open it out to size. Never use drill bits you intend to drill iron or steel with to drill such as timber! It will ruin them for steel working.

Send your message to us

PPGI Prepainted Galvanized Steel Coils for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords