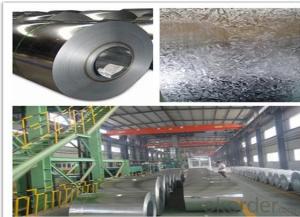

Hot Prepaint Galvanized Steel Coil and PPGI for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic description.

Surface Treatment:Coated

Technique:Cold Rolled

Standard:ASTM, JIS, GB

Application:Roof Panel,Wall Panel in Steel Structure Warehouse

Steel Grade:Q235B

Width:1000,1219,1200,1250mm

Thickness:0.17-1.0mm

Export Markets:Global

Additional Info.

Packing:Sea Packing: Standard Seaworthy Packing or Accordi

Standard:AISI, ASTM, BS, DIN, GB, JIS

Origin:Hebei, China

HS Code:72107010

Production Capacity:500, 000 Tons/Year

Product specification:

* Product Name: GALVANIZED STEEL COIL ,SGLCC

* Base Material: Galvanized Steel Coil.//SGLCC

* Width:700-,1250mm (The special width 914mm,1219mm,1220mm will be available )

* Thickness:0.3 -1.0mm Thickness tolerance: +/- 0.02mm

* Al-Zn coating: 30-150g /sq.m. or can be provided as clients' requirements

* Inner diameter of coil: 508mm&610mm.

* Packing: Standard seaworthy packing or according to user's need.

* Weight of each coil: 9 tons max

* Guarantee/ warranty

*Delivery time: Within 10-20 days.

USAGE

1.used as roof panel and wall panel in steel structure warehouse, factories, exhibition hall, container houses, cold storage,

2.it is also mainly used in light industry, automobile, construction, animal husbandry, fishery, and commerce,

PRODUCT PACKING

*Metal band strapping

*Outside diameter ring

*Label

*Protective steel sheet

*Water and rustproof paper

*Steel sheet

- Q: How are steel coils used in the manufacturing of exhaust systems?

- Steel coils are used in the manufacturing of exhaust systems as they provide the necessary material for forming and shaping various components such as pipes, mufflers, and catalytic converters. These coils are typically processed through cutting, bending, and welding techniques to create the required shapes and sizes for the different parts of an exhaust system.

- Q: How do steel coils withstand extreme temperatures?

- Steel coils are able to withstand extreme temperatures due to the unique properties of steel. Firstly, steel has a high melting point, allowing it to maintain its structural integrity even at extremely high temperatures. Additionally, steel has excellent thermal conductivity, which enables it to evenly distribute and dissipate heat. Furthermore, steel undergoes various heat treatment processes during manufacturing, such as quenching and tempering, which enhance its strength and resistance to temperature fluctuations. Overall, these factors make steel coils highly capable of withstanding extreme temperatures.

- Q: What are the common applications of steel coils in construction?

- Steel coils are commonly used in construction for various applications such as roofing, siding, structural framework, and reinforcement in concrete structures.

- Q: How are steel coils used in the automotive industry?

- Steel coils are used in the automotive industry to manufacture various components, such as body panels, frames, and suspension parts. These coils are transformed into flat sheets or molded into different shapes to meet the specific requirements of each component. The high strength and durability of steel make it an ideal material for ensuring safety and structural integrity in vehicles.

- Q: Can steel coils be coated with aluminum?

- Yes, steel coils can be coated with aluminum. The process is known as the hot-dip method, where the steel is first cleaned and then dipped into a bath of molten aluminum. This results in a protective layer of aluminum coating on the steel surface, enhancing its corrosion resistance and providing aesthetic appeal.

- Q: How are steel coils used in the production of electrical transmission towers?

- Steel coils are used in the production of electrical transmission towers as they are shaped and welded to create the structural framework of the towers. The coils are unrolled, cut, and formed into the required shape, providing strength and stability to support power lines and equipment.

- Q: Which one would be stronger? And should damascus steel be tempered?Thank You

- Damascus steel is in history books only,no body knows its composition.THey just named a modern steel as Damascus steel

- Q: How are steel coils used in the manufacturing of seat belts?

- Steel coils are used in the manufacturing of seat belts as they provide the necessary strength and durability to withstand the forces involved in a potential accident. These coils are typically used to reinforce the webbing of the seat belt, ensuring it can effectively restrain passengers in the event of a collision.

- Q: What is the standard diameter of steel coils?

- Depending on the industry and application, the standard diameter of steel coils may differ. Generally, steel coils have a standard diameter that falls between 24 inches and 72 inches. This range enables convenient handling, transportation, and storage of the coils. It is worth mentioning that various industries may impose specific requirements for steel coil diameters, taking into account factors like equipment compatibility, production processes, and logistical considerations.

- Q: What are the major challenges faced by steel coil manufacturers?

- Steel coil manufacturers encounter various obstacles across different areas. These challenges can be grouped into several key categories. Firstly, one of the primary hurdles is the fluctuating prices of raw materials, such as iron ore and coal, which are vital for steel production. To maintain profitability, manufacturers must constantly monitor and adjust their pricing strategies to mitigate the impact of these fluctuations. Secondly, intense competition arises from both domestic and international players in the steel coil manufacturing industry. Globalization has increased the availability of steel coils from various regions. Therefore, manufacturers must differentiate themselves through quality, pricing, and customer service to remain competitive. Thirdly, the steel industry is continuously evolving and adopting new technologies. Manufacturers need to invest in modern equipment and machinery to improve efficiency, reduce costs, and meet stringent quality standards. However, keeping up with technological advancements can be challenging, particularly for smaller or financially unstable manufacturers. Fourthly, steel production is a resource-intensive process that significantly impacts the environment. Governments worldwide have imposed stricter regulations on emissions, waste disposal, and energy consumption. Compliance with these regulations requires substantial investments in pollution control technologies and sustainable practices. Fifthly, the steel industry requires a skilled workforce with expertise in areas such as metallurgy, engineering, and operations. However, attracting and retaining skilled employees is challenging due to a shortage of qualified personnel. Manufacturers must invest in training and development programs to ensure a competent workforce and maintain operational excellence. Sixthly, steel coil manufacturers are highly sensitive to economic fluctuations. During economic downturns, demand for steel products decreases, leading to excess capacity and lower profit margins. Conversely, during economic booms, manufacturers may struggle to meet increased demand and ensure timely delivery. Lastly, transportation and logistics present a significant challenge for steel coil manufacturers due to the bulky and heavy nature of their products. Optimizing supply chain management, coordinating with freight partners, and ensuring timely delivery across various geographies can be complex and costly. In conclusion, steel coil manufacturers face challenges in several areas, including raw material costs, global competition, technological advancements, environmental regulations, skilled workforce requirements, economic volatility, and transportation logistics. Overcoming these challenges necessitates proactive strategies, continuous improvement, and a focus on innovation to remain competitive in the industry.

Send your message to us

Hot Prepaint Galvanized Steel Coil and PPGI for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords