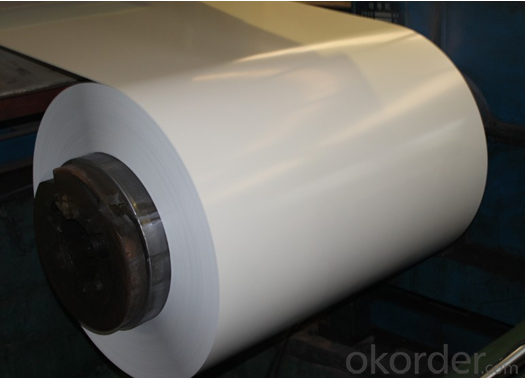

PPGI/Pre-Painted Galvanized Steel Roofing Sheet PPGI/Hot rolled coils/plates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot rolled coils/plates

Type: steel coil and steel plates

Material: SS400-Q235-Q345-SPHC

Width:1250mm 1500mm 1800mm 2000mm

HOT-ROLLED COIL/PLATES(Material: SS400-Q235A/B-SPHC) | |||

2.00*1250/1500L | 3.50*1250/1500L | 5.75*1250/1500L | 11.50*1250/1500L |

2.30*1250/1500L | 3.75*1250/1500L | 7.50*1250/1500L | 11.75*1250/1500L |

2.50*1250/1500L | 4.50*1250/1500L | 7.75*1250/1500L | 13.50*1250/1500L |

2.75*1250/1500L | 4.75*1250/1500L | 9.50*1250/1500L | |

3.00*1250/1500L | 5.50*1250/1500L | 9.75*1250/1500L | |

PATTERN-ROLLED COIL/PLATES(Material: Q235A-Q235B) | |||

3.00*1250L | 3.75*1250L | 4.75*1250L | 5.75*1250L |

3.50*1250L | 4.50*1250L | 5.50*1250L | 7.50*1250L |

MIDDEL-PLATE(Material: Q235A/B-Q345A/B) | |||

8*1800/2000L | 16*1800/2000L | 25*1800/2000L | 45*1800/2000L |

10*1800/2000L | 18*1800/2000L | 30*1800/2000L | 50*1800/2000L |

12*1800/2000L | 20*1800/2000L | 35*1800/2000L | |

14*1800/2000L | 221800/2000L | 401800/2000L | |

Name | galvanized steel coil dx52d z gi |

Grade | GB/T-12754: 2006, JIS3302, EN 10142, ASTM A653, JIS G3302, SGCC/SGCH, GB/T2518, European Standard, ASTM A792, JIS G3321, JIS G3317 |

BASE PLATE | Cold rolled steel sheet, hot dipped zinc coated steel sheet hot dipped A-Z coated steel sheet |

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

ZINC COATING | 40g-275g /m2 |

PAINT THICKNESS | Top:20+-5um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

BASE SHEET | Cold rolled steel sheet, hot dipped zinc coated steel sheet (small, regular or zero spangle), hot dipped A-Z coated steel sheet |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

Applications of cold rolled steel sheet coil :

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Process of cold rolled steel sheet coil :

Pay off reel-double cut shear-welder-notcher-entry accumulator-pre cleaning section-furnace-hot bridle-zinc pot-air knife-after cooler-water quench-dryer- skin pass mill-dryer-tension leveler-dryer-chemical coater-chemical oven-cooler-exit accumulator-oiler-exit shear-tension reel.

Features of cold rolled steel sheet coil :

1) cold rolled steel coils prices is manufactured to have a long durability, strong corrosion resistance and shiny surface.

2) cold rolled steel coils prices features excellent forming properties, paintability, weldability, and is suitable for fabrication by forming, pressing and bending.

FAQ

1.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

2. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

3.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

4. Is the sample available?

Yes, samples can be sent for test if you need.

- Q: What are the different types of steel coil coatings available?

- There are several different types of steel coil coatings available, including galvanized, galvalume, and organic coatings. Galvanized coatings are made by dipping the steel coil in a bath of molten zinc, providing excellent corrosion resistance. Galvalume coatings, on the other hand, consist of a combination of aluminum and zinc, offering enhanced corrosion protection and heat resistance. Organic coatings, such as polyester, polyvinylidene fluoride (PVDF), and silicone-modified polyester (SMP), are applied to steel coils using a roll coating process, providing a wide range of color and aesthetic options, as well as additional protection against weathering and UV radiation.

- Q: What are the different surface finishes for steel coils?

- Some common surface finishes for steel coils include hot rolled, cold rolled, galvanized, and coated finishes. Hot rolled coils have a rougher surface and are typically used for structural applications. Cold rolled coils have a smoother surface and are often used in applications requiring a high-quality finish. Galvanized coils are coated with a layer of zinc to protect against corrosion. Coated finishes include options like painted, epoxy, or vinyl coatings, which provide additional protection and aesthetic appeal.

- Q: I'm buying a new set of steel plugs.I've heard things about streched ears and cold weather not being to good. do you think it would be bad to be wearing steal plugs?

- It depends on the person. Sometimes cold weather makes stretched ears feel tight, like tighter against plugs. I never felt this, and my friends never have either(at least they say they haven't). Go ahead and wear them, but if you feel any discomfort, just change them out.

- Q: How are steel coils used in the automotive stamping industry?

- Steel coils are used in the automotive stamping industry to provide a continuous supply of flat steel sheets that are then fed into stamping machines. These coils are unrolled, straightened, and then fed through the stamping presses to create various automotive parts, such as body panels, chassis components, and other structural parts. The use of steel coils ensures efficiency, precision, and a consistent quality in the production of automotive parts.

- Q: Why are properties of steel not identical?

- Steel is manufactured to different specs. To match the needs of its intended end use .Tensel strength,Hardness, Corosion resistance etc. The chemical make up will change to suit.

- Q: How are steel coils inspected for coil weight accuracy after processing?

- Steel coils are typically inspected for coil weight accuracy after processing by using weighing scales or load cells that are capable of accurately measuring the weight of the coil. The coil is placed on the scale or load cell, and the weight is compared to the target weight specified for that particular coil.

- Q: We have to do a project for school on steel mines and i need 4 PROPERTIES OF A STEEL MINE PLEASE HELP!!! URGENT!!!

- There's no such thing as a Steel mine - steel is made from various raw materials (and now recycled metals). These materials may be mined separately and then combined at a steel mill - but steel is made, not mined. Steel, depending on what final characteristics they're trying to develop (strength, hardness, finish , etc.) can be comprised of iron, carbon, manganese, phosphorus, sulfur, nickel, chromium, etc. in varying quantities.

- Q: How are steel coils inspected for flatness?

- Steel coils are inspected for flatness using various methods, such as visual inspection, measuring the crown or center buckle, and conducting a straight edge test. These techniques help assess any deviations or unevenness in the coil's surface, ensuring that it meets the required flatness standards.

- Q: Ive been playing with my ping i3 graphite irons for 6 years now and some days i can hit it and some days i cant. Then i tried out my friends irons the other day and he had steel and i was hitting the ball anywhere i wanted it to go..Is that a fluke or is steel irons just better than shaft? I was thinking about trading my graphites for steel, is that a good idea??

- Ping Graphite Iron Shafts

- Q: I know that the steel is significantly harder than when air cooled, but why is the quenched steel harder?

- When steel is slowly cooled, lots of carbon diffusion takes place because it is not very soluble in steel at room temperature. The carbon is in solution at high temperatures, and is rejected out of the lattice as it cools. And when this happens, the microstructure will consist of ferrite and pearlite, and the lattice structure will be base centered cubic (bcc). If it is cooled fast enough, then the carbon gets trapped in the interstitial sites of the lattice and distorts it to a body centered tetragonal (same as bcc, but elongated in one direction) This elongation strains the lattice and makes it harder. Also, when cooled fast enough the atoms do not have time to diffuse like they normally would and they shear into place. This forms the hard phase of martensite that is desired of heat treated steel. But then it must be tempered back some because it is too brittle.

Send your message to us

PPGI/Pre-Painted Galvanized Steel Roofing Sheet PPGI/Hot rolled coils/plates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords