Aluminum Coil Coating - PPGI Colorful Pre-Painted Galvalume Zinc Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of PPGI Colorful Pre-painted Galvalume Zinc Aluminum Coil Coating

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of PPGI Colorful Pre-painted Galvalume Zinc Aluminum Coil Coating

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PPGI Colorful Pre-painted Galvalume Zinc Aluminum Coil Coating

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

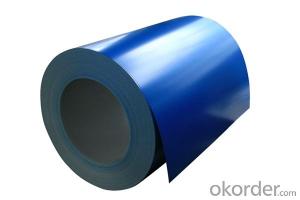

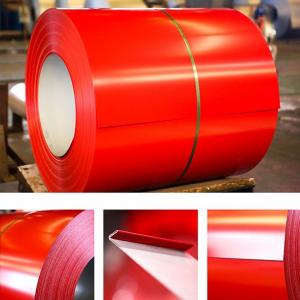

5. Image of PPGI Colorful Pre-painted Galvalume Zinc Aluminum Coil Coating

6. Package and shipping of PPGI Colorful Pre-painted Galvalume Zinc Aluminum Coil Coating

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum coils compare to other types of coils (e.g., copper)?

- Aluminum coils generally have a lower cost compared to copper coils, making them a more budget-friendly option. However, copper coils tend to have better heat transfer properties and are more durable, which can result in improved system performance and longer lifespan. The choice between aluminum and copper coils depends on factors such as budget, desired efficiency, and specific application requirements.

- Q: What are the proper storage methods to maintain the quality of aluminum coil for future use?

- <p>To store aluminum coil for future use, ensure it is kept in a cool, dry place away from direct sunlight and moisture. Stack the coils on flat, level surfaces with appropriate padding to prevent damage. Avoid stacking with other metals to prevent galvanic corrosion. Use clean, dry hands or gloves when handling to prevent oil and dirt from contaminating the surface. Store in a controlled environment with a relative humidity below 65% and a temperature between 32掳F to 90掳F (0掳C to 32掳C). Regularly inspect the coils for any signs of corrosion or damage.</p>

- Q: Are aluminum coils suitable for cryogenic applications?

- Yes, aluminum coils are suitable for cryogenic applications. Aluminum has a number of properties that make it an excellent choice for use in low-temperature environments. Firstly, aluminum has a low melting point, which means it remains solid and maintains its structural integrity at cryogenic temperatures. This is crucial for applications where extreme cold temperatures are involved, such as in cryogenic storage or transportation. Additionally, aluminum has good thermal conductivity, which allows for efficient heat transfer. In cryogenic applications, it is important to manage and control heat flow to prevent temperature fluctuations or thermal stress. Aluminum coils can effectively transfer heat away from the system, ensuring stable and consistent temperatures. Furthermore, aluminum is lightweight and has a high strength-to-weight ratio. This makes it highly advantageous for cryogenic applications, where weight and space considerations are often critical. Aluminum coils can help reduce the overall weight of the system, making it more efficient and cost-effective. Lastly, aluminum is corrosion-resistant, which is essential in cryogenic environments where moisture or other corrosive substances may be present. Aluminum coils can withstand the harsh conditions and maintain their performance and durability over extended periods of time. Overall, due to its low melting point, good thermal conductivity, lightweight nature, and corrosion resistance, aluminum coils are indeed suitable for cryogenic applications. They offer numerous benefits and can effectively meet the requirements of such demanding environments.

- Q: What advantages does 0.1*100cm aluminum coil have? Is it suitable for the roof tiling? How is the anti-oxidation and anti-corrosion performance?

- 0.1 aluminum sheet has no intensity, so 0.5-1mm colored steel is often used to make roofing.

- Q: What is the common color of aluminum coil membrane?

- The blue transparent membrane is the most common.

- Q: Are aluminum coils suitable for coil winding applications?

- Coil winding applications can utilize aluminum coils, as they possess numerous advantageous properties. Firstly, aluminum is lightweight, facilitating easier handling and transportation. Industries like automotive and aerospace, which prioritize weight reduction, find this particularly beneficial. Moreover, aluminum exhibits excellent conductivity, ensuring efficient electrical current flow within the coil. This is especially advantageous for applications requiring high performance and low resistance, such as transformers and electric motors. Additionally, aluminum's high resistance to corrosion renders it suitable for outdoor and harsh environments. Unlike metals like steel, it does not rust and can endure exposure to moisture and chemicals. Furthermore, aluminum coils offer cost-effectiveness. Compared to metals like copper, commonly used in coil winding, aluminum is generally more affordable. Thus, it presents a cost-efficient option for various industries. Nevertheless, it is important to acknowledge that aluminum has lower electrical conductivity than copper. Therefore, in applications where high conductivity is paramount, such as power transmission, copper coils may be more suitable. Nonetheless, aluminum coils provide numerous benefits and find widespread use in various coil winding applications.

- Q: Are there any specific certifications or qualifications required for aluminum coil suppliers?

- Certifications and qualifications that are essential for aluminum coil suppliers do exist. The ISO 9001 certification is a vital one for these suppliers as it guarantees the implementation of a quality management system and adherence to international quality standards. When a supplier possesses this certification, it demonstrates their effective quality control processes, consistent product performance, and ability to satisfy customers. Another critical qualification for aluminum coil suppliers is the AS9100 certification, particularly for those serving the aerospace industry. This certification verifies that the supplier has fulfilled the industry-specific requirements for quality management systems, including rigorous quality control, traceability, and compliance with industry standards. Moreover, aluminum coil suppliers may also need to conform to industry-specific standards like the ASTM standards or the REACH regulations of the European Union concerning chemical substances. These standards ensure that the supplier's products fulfill the necessary specifications and are safe to use in various applications. Furthermore, certain aluminum coil suppliers may possess specialized certifications or qualifications tailored to specific industries or applications. For instance, suppliers serving the automotive industry may hold certifications like the IATF 16949 certification, which demonstrates their ability to meet the demanding requirements of automotive manufacturers. In conclusion, while the specific certifications and qualifications required may vary depending on the industry and application, it is crucial for aluminum coil suppliers to possess certifications like ISO 9001 and industry-specific certifications to ensure their products meet the required quality standards and comply with relevant regulations.

- Q: The export of aluminum coil, according to steel coil declaration, will there be any problems?

- If you have already declared itCheck the corresponding HS code, to import countries taxes and fees are the same, whether the customer side mind?.China's tax rebate rate, you also see what kind of high?.In addition to export will have a steel coil sampling, aluminum volume difference is relatively large, so if the declaration, to take note of this, if the sampling try with conversational communication forwarding, otherwise it would be a big problem.

- Q: The user is inquiring about the possibility of reusing their old aluminum coils or purchasing used ones.

- <p>Yes, you can reuse your old aluminum coils if they are still in good condition and meet the required specifications for your application. Reusing can be cost-effective and environmentally friendly. When buying used coils, ensure they are from a reputable source and have been properly inspected for any damage or wear that could affect performance. It's crucial to verify the coils' integrity and functionality before use to avoid any potential issues in your manufacturing or production process.</p>

- Q: What is the typical modulus of elasticity for aluminum coils?

- Aluminum coils typically have a modulus of elasticity of approximately 70 GPa (gigapascals) or 10 million psi (pounds per square inch). The modulus of elasticity gauges a material's inflexibility or capacity to withstand distortion under an external force. Aluminum is renowned for its impressive strength-to-weight proportion and remarkable elasticity, rendering it a favored option across diverse sectors such as automotive, aerospace, and construction. Nonetheless, it is noteworthy to acknowledge that the modulus of elasticity may slightly differ depending on the particular alloy and temper of the aluminum coil.

Send your message to us

Aluminum Coil Coating - PPGI Colorful Pre-Painted Galvalume Zinc Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords