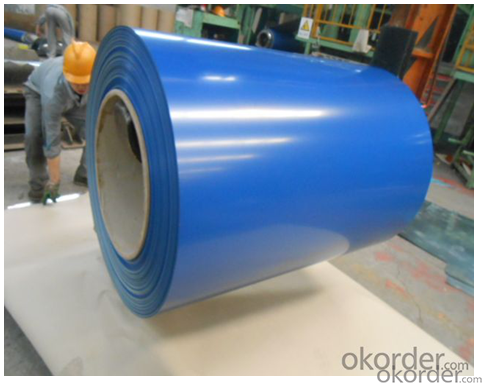

PPGI Color Coated Galvanized Steel Coil Bule Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of oil and gas equipment?

- Steel coils are used in the manufacturing of oil and gas equipment to create various components such as pipes, tanks, and pressure vessels. These coils are shaped, cut, and welded to form the required structures, ensuring strength, durability, and resistance to extreme conditions encountered in the oil and gas industry.

- Q: What are the different types of welding used for steel coils?

- There are several different types of welding used for steel coils, depending on the specific requirements and applications. Here are some of the most common types of welding techniques used for steel coil fabrication: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, it involves the use of a flux-coated electrode and an electric current to create an arc between the electrode and the base material. SMAW is a versatile and widely used welding technique suitable for various steel coil applications. 2. Gas Metal Arc Welding (GMAW): Commonly known as MIG (Metal Inert Gas) welding, GMAW uses a continuous wire electrode and a shielding gas to protect the weld pool from atmospheric contamination. GMAW is known for its high welding speed and ease of automation, making it a popular choice for steel coil manufacturing. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a tubular electrode with flux inside. The flux provides both the shielding gas and additional alloying elements, resulting in increased efficiency and improved weld quality. FCAW is often used in high-speed welding applications for steel coils. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode and an inert gas, typically argon, to shield the weld area. GTAW produces high-quality, precise welds with excellent control over the heat input, making it suitable for thin steel coil materials and critical welding applications. 5. Submerged Arc Welding (SAW): This welding technique involves the use of a continuously fed wire electrode and a granular flux that covers the weld area. The arc is submerged under the flux, providing excellent protection and reducing the need for post-weld cleaning. SAW is commonly used for welding thick steel coils due to its high deposition rates and deep penetration capabilities. These are just a few examples of the different types of welding techniques used for steel coil fabrication. The choice of welding method depends on factors such as the specific steel grade, thickness, desired weld quality, production speed, and cost considerations. It is essential to select the appropriate welding technique to ensure the durability and performance of the steel coils in various applications.

- Q: What are the factors affecting the corrosion resistance of steel coils?

- There are several factors that can affect the corrosion resistance of steel coils. These factors include the composition of the steel, the presence of impurities or alloying elements, the surface finish or coating on the coils, the environmental conditions such as humidity and temperature, and the presence of corrosive chemicals or substances in the surrounding atmosphere. Additionally, factors such as handling and storage practices can also impact the corrosion resistance of steel coils.

- Q: How are steel coils processed for cold rolling or hot rolling?

- Steel coils are first unwound and inspected for any defects. Then, they are cleaned and treated to remove any impurities. For cold rolling, the coils are passed through a series of rollers at room temperature to reduce their thickness and improve their surface finish. On the other hand, for hot rolling, the coils are heated to high temperatures and then passed through rollers to achieve the desired thickness and shape.

- Q: Why?Which one should i get? I am just starting to learn Guitar. Which one would be better for me? What is the difference? I already got the acoustic nylon but i might return it... if the steel is better.

- I find for beginners nylon is better. You won't get as many blisters and nylon strings are easier to bend. Check out my website for some free lessons and free bonus info for the exact answer you are looking for

- Q: does regular steel rust? or is it all the same.

- Rusting is what steel, or any iron alloy, does best. Stainless steels rely on a small amount of either nickel or chromium, or occasionally some other element, to protect it. What these do is they actually oxidize faster than the iron does but this oxidation forms a microscopically thin, effectively invisible, but very tough coating of oxide that then protects the rest of the metal.

- Q: What is the difference between hot rolled and cold rolled steel coils?

- The main difference between hot rolled and cold rolled steel coils is the process by which they are made. Hot rolled steel coils are produced by heating the steel above its recrystallization temperature, allowing it to be easily shaped and formed. This process results in a rougher surface finish and less precise dimensions. On the other hand, cold rolled steel coils are produced by further processing hot rolled coils through a series of rolling mills at room temperature. This process results in a smoother surface finish, tighter tolerances, and improved mechanical properties.

- Q: Will a 8mm steel ball fired from a 150lbs crossbow kill small game and if so, from how many yards?

- An 8mm steel ball fired from a 150# crossbow is probably going to damage your crossbow. Crossbows shoot arrows (or bolts), NOT ball bearings and, furthermore, a 150# crossbow needs an arrow (or bolt) of about 450 grains in order to be efficient and operate without damaging itself. A 450 grain arrow will kill small game very well and out to a range of about 30 yards. Don't wind up like the guy below... EDIT: Racing Pace Stick - I stand corrected. There are, indeed, tacticool crossbows that shoot ball bearings and they all seem to come straight from Shandong Province, China. Note that these are not implements suited to hunting. Also note that if you shoot an 8mm steel ball out of a 150# draw compound crossbow that IS suitable for hunting, you are probably going to break it.

- Q: What are the different methods of edge camber correction for steel coils?

- There are several methods used for edge camber correction in steel coils, depending on the specific requirements and equipment available. Some of the common methods include: 1. Mechanical Edge Trimming: This method involves trimming the edges of the coil using mechanical tools such as shears or slitters. It helps to remove excess material and correct the camber. This method is often used for smaller coils or when the camber is minimal. 2. Tension Leveling: Tension leveling is a process where the coil is passed through a series of adjustable rollers under tension. The tension helps to elongate the steel and reduce the camber. This method is effective for correcting moderate camber and is commonly used for larger coils. 3. Roller Leveling: Roller leveling is similar to tension leveling, but instead of adjustable rollers, the coil is passed through a series of fixed rollers. These rollers exert pressure on the steel to flatten it and correct the edge camber. This method is often used for thicker and heavier coils. 4. Heat Straightening: Heat straightening involves applying controlled heat to the edges of the coil to soften the steel. Once the steel becomes malleable, external force is applied to straighten the edges. This method is suitable for correcting severe edge camber but requires specialized equipment and expertise. 5. Combination Methods: In some cases, a combination of different methods may be used to achieve the desired edge camber correction. For example, mechanical edge trimming may be followed by tension leveling or roller leveling to further straighten the edges. It is worth mentioning that the choice of method depends on various factors such as the severity of camber, coil dimensions, material properties, and available equipment. It is essential to evaluate these factors and consult with experts to determine the most suitable method for edge camber correction in steel coils.

- Q: haii, i have this guitar thats quite old and im not quite sure whether to put steel strings on it. there were very thin badly worn steel strings on it when i got it, so i think its an acoustic

- That's a very low-end Kay, maybe from the 60's or 70's. It has a weird mixture of steel-string and classical features that you often see in cheap imports from around that time, maybe because the factory didn't want to stock different parts for different lines. The tuners (one of which is missing) are made for steel strings. They will work with nylon but not well. The bridge is a generally classical type but appears to be bolted on and seems to have some compensation carved into the saddle, which indicates it may have been intended for steel strings. Probably it's ladder braced, which is not a great design for either type. It has a classical rosette and a steel-string pickguard. I am guessing the neck has steel reinforcement but unless there's a sticker there's no way to tell. Personally I'd put light or (preferably) extra-light steel strings on it. The short scale length will help keep the tension down. I'd keep an eye on the neck though. You could also try silk steel to be on the safe side, but the bass response will probably be lacking.

Send your message to us

PPGI Color Coated Galvanized Steel Coil Bule Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords