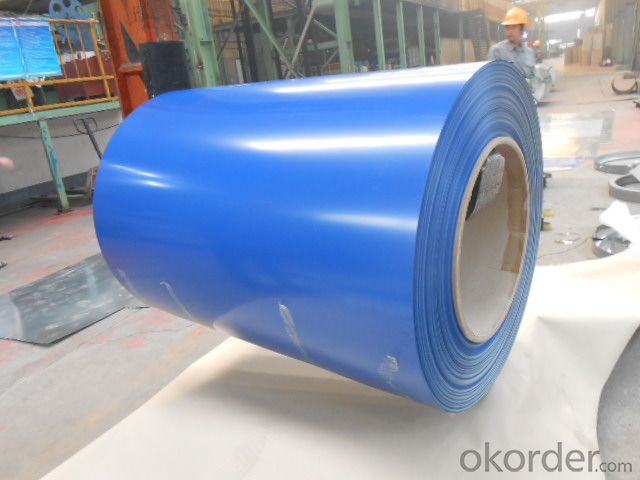

PPGI Color Coated Galvanized Steel Coil Prime Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What products can we make with steel (eg Steel strip, rod, bar, rail, tube) How are these made? What can we make from these steel products?Can you please make the answers as detailed as possible you can because i really want to know this really well. Thank you.

- Your okorder (they make steel deck and steel joists) There are thousands of other items routinely produced from steel, including rebar, and all the metal in cars, airplanes, and about a million other things.

- Q: How do steel coils contribute to the energy infrastructure sector?

- Steel coils play a vital role in the energy infrastructure sector by providing the necessary materials for the construction and maintenance of various energy-related structures and equipment. Firstly, steel coils are widely used in the production of pipelines, which are the lifelines of the energy industry. These pipelines transport oil, natural gas, and other energy resources over long distances, ensuring a steady supply to power plants and other energy facilities. Steel coils are used to manufacture seamless and welded pipes that possess high strength, durability, and resistance to corrosion, making them suitable for handling the harsh conditions of energy transportation. In addition to pipelines, steel coils are used in the production of storage tanks for oil, natural gas, and other fuels. These tanks are crucial for storing large quantities of energy resources, ensuring a continuous supply even during periods of high demand. Steel coils are utilized to fabricate the tank shells, providing the necessary strength and structural integrity to withstand the pressure and environmental factors associated with energy storage. Furthermore, steel coils are instrumental in the construction of power plants and other energy infrastructure facilities. They are used to manufacture structural components such as beams, columns, and supports, which provide the foundation and stability required for the safe operation of these facilities. Steel coils also contribute to the production of equipment such as turbines, generators, and transformers, which are essential for converting energy into usable forms and distributing it to end-users. Moreover, steel coils are utilized in the construction of transmission towers and electrical grids. These structures and networks are responsible for transmitting electricity from power plants to residential, commercial, and industrial consumers. Steel coils are used to manufacture the towers and poles that support high-voltage transmission lines, ensuring their stability and reliability in transmitting electricity over long distances. In summary, steel coils are indispensable in the energy infrastructure sector as they provide the necessary materials for the construction, maintenance, and operation of pipelines, storage tanks, power plants, transmission towers, and electrical grids. Their strength, durability, and resistance to corrosion make them an ideal choice for withstanding the demanding conditions of the energy industry, thereby ensuring a reliable and efficient energy supply to meet the growing needs of society.

- Q: for instance Cr-Ni steeldoes this refer to plated steel or a uniform mixture

- stainless steel is an alloy normally iron with additions of C, Mn, Ni, Cr, and Nb - amounts added depend on properties required. Corrosion resistance is due to a very thin but dense layer of chromium oxide which forms at the surface and prevents further attack. Ordinary steel on the other hand becomes coated with a porous layer of iron oxide(rust) through which the atmosphere can pass and cause further corrosion.

- Q: How are steel coils used in the manufacturing of garage doors?

- Steel coils are used in the manufacturing of garage doors as they are the primary material for constructing the door panels. These coils are first formed into thin, flat sheets and then cut to the desired size. The sheets are then shaped and reinforced to create the panels that make up the structure of the garage door. The strength and durability of steel make it an ideal material for garage doors, providing security, insulation, and longevity.

- Q: How are steel coils used in the production of wire products?

- Steel coils are an essential component in the production of wire products. These coils are typically made from high-quality steel and are used as a raw material for wire drawing processes. Wire drawing is a manufacturing technique used to reduce the diameter of the steel coil and transform it into various wire products. To begin the process, a steel coil is placed on a wire drawing machine. The machine then pulls the coil through a series of dies, which are progressively smaller in size. As the coil passes through each die, the diameter of the wire is reduced, resulting in a thinner and longer strand of wire. This process can be repeated several times until the desired wire thickness is achieved. Once the wire is drawn, it can be further processed to create various wire products such as fencing, nails, screws, springs, and electrical wires. The wire can be cut to specific lengths, bent, or shaped according to the intended use. Additionally, it can undergo treatments such as galvanizing or coating to enhance its durability and resistance to corrosion. Steel coils provide several advantages in the production of wire products. Firstly, they offer a consistent and uniform material, ensuring that the resulting wire products have consistent quality and performance. Secondly, steel coils are easily transportable and can be stored efficiently, making them a cost-effective option for manufacturers. Lastly, the versatility of steel allows for the production of wire products with different tensile strengths and properties to meet specific industry requirements. In conclusion, steel coils play a crucial role in the production of wire products. They are the primary raw material used in wire drawing processes, where they are transformed into various wire products through a series of reduction steps. The resulting wire products find applications in a wide range of industries, making steel coils an indispensable component in the manufacturing sector.

- Q: What is the average thickness tolerance for steel coils?

- The average thickness tolerance for steel coils can vary depending on the specific industry and application. However, a common average thickness tolerance for steel coils is typically around ±0.005 to ±0.010 inches.

- Q: Hi, does anyone know where i can find more about this topic ? fire resistant steels for structural applications. thanks

- In the fire protection world, we do not consider steel fire resistant. Of course it doesn't burn under ordinary conditions, but it lose strength as it is heated. As has been mentioned, there are coatings which insulate steel to enable it to withstand high ambient temperatures for a long time. Construction using this method is called fire resistive construction.

- Q: We are going to build a house with a steel frame.Someone told me today that these houses have problems with humidity.Is that true?Please tell me all you know..

- the building I work in is steel framed, no humidity problems. I can't believe that steel frame anything causes humidity problems. I would ask for an explanation from whom ever told you this. One thing is cell phones, radios etc. have bad reception due to all the interference.

- Q: What are the different methods of coil recoiling for narrow strip widths?

- Some of the different methods of coil recoiling for narrow strip widths include slitting and rewinding, oscillating winding, and turret winding.

- Q: How are steel coils processed for edge trimming or shearing?

- Steel coils are processed for edge trimming or shearing through a series of steps. First, the coil is unwound and passed through a leveller to ensure a flat surface. Then, the edges are inspected for defects and marked for trimming. Next, the coil is fed into a shearing machine or a slitting line, where the excess material is cut off to achieve the desired width. Finally, the trimmed coil is rewound and prepared for further processing or shipment.

Send your message to us

PPGI Color Coated Galvanized Steel Coil Prime Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords