PPGI Color Coated Galvanized/Aluzinc Steel Sheet in Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

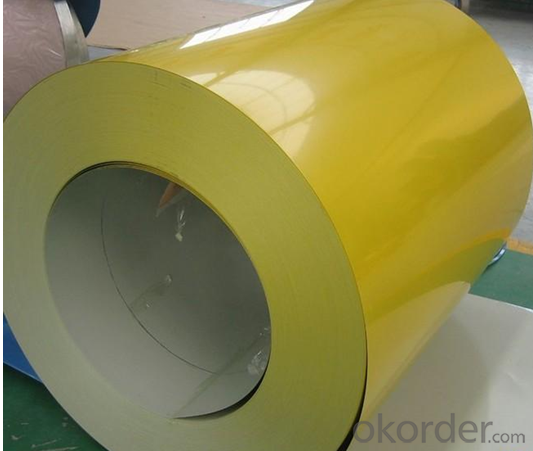

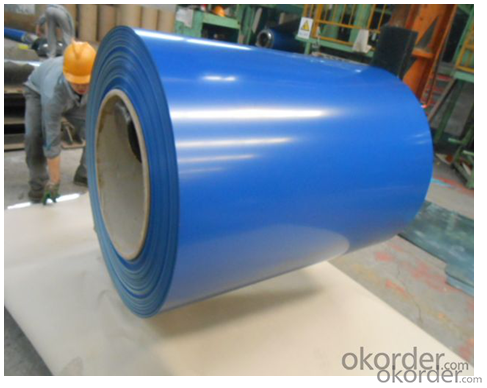

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: I am in the US and looking for a price on wide flange steel. I need a price of one W10x30 and 20 feet long.

- The price of steel is increasing daily, so an exact answer is rough. A W10x30 is a fairly common shape and shouldn't be too hard to find. For a very rough ballpark number, say $700/ton (installed price), the piece you require should be in the range of about $250.00 or less as I assume you'll be doing the installing. Please don't take this as the gospel, however. Price varies on location, stock, and availability. Open the phone book and contact your local steel supplier. Because the piece you require is fairly short, you might get lucky and find someone who has a waste piece that length that they will give you a good deal on. --------------------------------------... I just checked the AISC web site to verify the number I quoted above and they posted an article stating that the average mill price had just increased to over $1000/ton in May. The best advice I can provide at this point is to buy the W10 now and don't wait any longer.

- Q: I know aluminum is lighter but I'm looking at a 01 bianchi grizzly mountain bike which is steel. I used to ride a specialized stumpjumper m4 which was aluminum. It was quite light so I don't know if I'll like a bit heavier bike but overall what is better from those who have had both?

- Depending on the price, aluminum may be as heavy or heavier than steel... don't let anyone tell you otherwise. Keep in mind that with age aluminum will eventually break from stress while steel will never fail due solely to riding stresses. In all, it is up to you. I ride steel or magnesium road bikes and aluminum or magnesium MTBs.

- Q: Can steel coils be coated with fluorescent materials?

- Yes, steel coils can be coated with fluorescent materials.

- Q: Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or recessed designs on a material's surface, and it can be done on various materials, including steel.

- Q: What are the common methods of painting or coating steel coils?

- One common method of painting or coating steel coils is through the process of coil coating. In coil coating, the steel coils are first cleaned and pre-treated to remove any contaminants and improve adhesion. Then, a primer or a base coat is applied to the coils to provide a foundation for the final coating. This primer helps in protecting the steel from corrosion and improves the overall durability of the coating. After the primer is applied, the steel coils pass through a series of rollers where the topcoat is applied. The topcoat can be a variety of materials such as polyester, polyurethane, or fluoropolymer, depending on the desired properties of the final coating. These topcoats provide the desired color, gloss, and protection against weathering, chemical exposure, and UV radiation. Another common method of painting or coating steel coils is through the process of electrostatic spraying. In this method, a paint or coating material is atomized into fine droplets and then charged with an electrical charge. The steel coils, which are grounded, attract the charged droplets, resulting in an even and controlled application of the paint or coating material. Powder coating is yet another method used for painting or coating steel coils. In this process, a dry powder is electrostatically charged and sprayed onto the steel coils. The charged powder adheres to the surface of the steel due to electrostatic attraction. The coated steel coils are then heated, causing the powder to melt and form a continuous film, providing a durable and resistant coating. Overall, these methods of painting or coating steel coils offer a wide range of options in terms of color, finish, and performance characteristics. The choice of method depends on factors such as the desired appearance, level of protection needed, and the specific requirements of the intended application.

- Q: How are steel coils used in the production of metal roofing panels?

- The production of metal roofing panels relies heavily on steel coils, which are rolled sheets of steel. These coils play a crucial role in shaping and forming the panels. To begin, a machine called a roll former is used to unwind and feed the steel coils. This machine gradually shapes and bends the steel into the desired profile of the metal roofing panel using a series of rollers and dies. The coils pass through these rollers, which apply pressure and force to mold the steel into the required shape and size. After the metal has been formed into panels, it may undergo additional processes to enhance its durability and appearance. These processes can include galvanizing or coating the panels with protective layers to prevent corrosion and improve weather resistance. These additional steps ensure that the metal roofing panels can withstand harsh environmental conditions and provide long-lasting performance. Steel coils are chosen over other materials for the production of metal roofing panels because of their strength and durability. Steel has an exceptional strength-to-weight ratio, making it a suitable material for roofing applications. Additionally, steel is highly resistant to various weather conditions such as high winds, heavy rains, and extreme temperatures. This makes it an ideal choice for roofing panels that need to withstand the elements and provide reliable protection for buildings. In conclusion, steel coils are an essential component in the manufacturing process of metal roofing panels. They are used to shape and form the panels, which then undergo further processing to enhance their durability. The use of steel in these panels ensures that they can withstand harsh weather conditions and provide long-lasting performance for residential, commercial, and industrial buildings.

- Q: I am trying to clean up a stainless steel back splash and some kitchen appliances that have brown spots that look like rust spots. I was able to remove most of them with stainless steel cleaner but does anyone know any tricks?

- Contrary okorder /

- Q: I personally don't believe the story of 8 guys who flew small planes can navigate passenger jets into buildings hundreds of miles away with that precision. It just doesn't make sense.I am wondering what the story surrounding the molten steel was, how could molten steel have been produced when fuel from the planes wasn't hot enough (it melts at 2850 degrees)?

- that's just it: there wasn't very much molten steel for the very reason you point out. Jet fuel burns at 800° to 1500°F. This is not hot enough to melt structural steel. However, engineers say that for the World Trade Center towers to collapse, their steel frames didn't need to melt, they just had to lose some of their structural strength. Steel will lose about half its strength at 1,200 degrees F. The steel will also become distorted when heat is not a uniform temperature. after the collapse, a LOT of folks took a look at the remains. the result was the conclusion that the fire caused the central core of the building to weaken. When the floors collapsed one on top of the other, the weight was too much for the weaked core to bear, causing the result we are all familiar with. hope this helps

- Q: What are the challenges in welding steel coils?

- Some challenges in welding steel coils include potential distortion due to heat, ensuring consistent and strong welds along the entire length, managing the high temperatures involved, and avoiding defects such as porosity or cracking. Additionally, the large size and weight of the coils can pose logistical challenges for handling and positioning during the welding process.

- Q: What is the average flatness tolerance for steel coils?

- The average flatness tolerance for steel coils typically ranges between 0.25% and 0.5% of the coil's width.

Send your message to us

PPGI Color Coated Galvanized/Aluzinc Steel Sheet in Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords