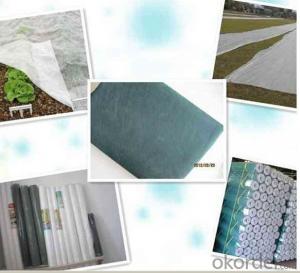

Best Geotextile PP Spunbonded Nonwoven Fabric Blue and Red

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Spunbonded Nonwoven Fabric different color for agriculture

Specification of Polypropylene Spunbond Non Woven Fabric:

| | |

Material | 100% Polypropylene/100%PP |

Width | 0.4--3.2M |

Color | Any color available |

Roll Length | According to your requirement |

Technics | Nonwoven |

Nonwoven Technics | Spunbonded |

Pattern | Yarn Dyed |

Weight | 9-200GSM |

Style | Plain |

Feature | Waterproof,Mothproof,Eco-friendly,Non-toxic,Breathable,Anti-Bacteria |

Certification | ISO9001 |

Usage | Agriculture,Indrustry,Construction,Packaging,Home-textitle, etc |

MOQ | 1Ton/1000KG |

Payment Terms | T/T or L/C |

Delivery Time | Within 7-15 days |

Packaging Detail | Plastic film in roll |

| Shandong,China |

Loading of Port | Qingdao |

Sample | Free samples are available |

Introduction of polypropylene spunbond non woven fleece fabric is used to protect the crops in agriculture UV resistance masterbatch could be added 1%~8%. It can protect the vegetable crops and new lawns against extreme weather, animal and insect damage, yet allows light, water and air to penetrate, creating protected growing conditions..

- Q: What is the separation between the roof waterproof protective layer and the waterproof layer?

- The meaning of the protective layer and the isolation layer is not the same, figured out the role and meaning of nature know how to set up. 1, the protective layer of the waterproof layer contains a two-tier meaning. First, if there are other waterproof layer above the construction layer, due to the construction process may cause damage to damage to water, so need to do protective layer; Second, the roof is the function of the master or planting, the activities of personnel may cause damage to water , Need to do protective layer. 2, the role of the isolation layer is also divided into two kinds. First, to prevent the adverse effects of the two kinds of materials (incompatible), with the isolation layer for the interface, such as PVC coil and polystyrene foam insulation board, because the plasticizer in the membrane will migrate , The direct contact with the benzene plate will produce melt damage; Second, the coil surface of the rigid layer, may be due to thermal expansion and contraction deformation affect the waterproof layer, in the rigid layer of the larger part of the deformation, Too large and damage the waterproof layer, then need to set the isolation layer. There is a geotextile isolation layer between the waterproofing membrane and the pebble press material. 3, not all of the waterproof layer and the protective layer between the need for isolation layer. When the cement mortar is used as the protective layer, the cement mortar may be directly applied to the waterproof surface. When the flexible protective material (heat reflective coating, etc.) or the insulation layer is used, the isolation layer is not required.

- Q: Can geotextiles be used in embankment reinforcement?

- Yes, geotextiles can be used in embankment reinforcement. Geotextiles are commonly used in civil engineering projects to improve the stability and performance of embankments. They provide reinforcement by distributing loads and reducing soil erosion, thereby enhancing the overall strength and durability of embankments.

- Q: What are the design considerations for geotextile-reinforced soil walls?

- Some design considerations for geotextile-reinforced soil walls include selecting the appropriate geotextile material, determining the optimal spacing and orientation of the reinforcement, ensuring proper compaction of the soil, considering the impact of water on the wall's stability, and accounting for any potential settlement or creep in the soil over time. Additionally, factors such as the height of the wall, the slope angle, and the overall stability and strength requirements must also be taken into account during the design process.

- Q: Geotextile effect

- First, the drainage effect: polyester staple acupuncture geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas efflux. Second, the role of contraction: When the water from the fine soil into the coarse soil layer, the use of polyester staple acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand , Small stone, etc., in order to maintain the stability of soil and water engineering. Third, the isolation role: the use of polyester staple acupuncture geotextile with different physical properties of the building materials to isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. Fourth, the role of puncture: and geomembrane combined into a composite waterproof impermeable material, play the role of anti-puncture. High tensile strength, good permeability, breathable properties, high temperature resistance, anti-freeze, anti-aging, corrosion-resistant, not moth-eaten. Polyester staple acupuncture geotextile is a widely used geosynthetics.

- Q: Can geotextiles be used in coastal erosion control in beach nourishment projects?

- Yes, geotextiles can be used in coastal erosion control in beach nourishment projects. Geotextiles are commonly used as a protective barrier to prevent erosion and stabilize the shoreline. They can be placed under the sand or gravel layer in beach nourishment projects to enhance the stability and longevity of the beach, reducing the impact of wave action and promoting sediment retention.

- Q: What are the different geotextile specifications and standards?

- There are various geotextile specifications and standards that are used to ensure the quality and performance of geotextile materials. Some of the commonly recognized specifications and standards include ASTM D6389, ASTM D4533, and ISO 10318. These standards outline the testing methods, physical properties, and performance requirements for geotextiles in various applications. Additionally, different countries and regions may have their own specific specifications and standards that are followed for geotextile products. Overall, these specifications and standards help to ensure the consistency and reliability of geotextile materials in engineering and construction projects.

- Q: How do geotextiles help with soil stabilization?

- Geotextiles help with soil stabilization by providing a barrier that separates the soil layers, preventing them from mixing and maintaining their structural integrity. This prevents erosion, improves drainage, and enhances the overall stability of the soil, reducing the risk of slope failure and ensuring long-term stability of the area.

- Q: What is the geotextile for ditch drainage?

- Generally used polyester short wire geotextile, the specifications are 300g per square meter

- Q: In the laying of composite geotextile water layer, what is wf115-0.2mm type

- I produce geotextile materials

- Q: Do you need to use geotextile for construction site? Mainly used where?

- Underground garage roof green

Send your message to us

Best Geotextile PP Spunbonded Nonwoven Fabric Blue and Red

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords