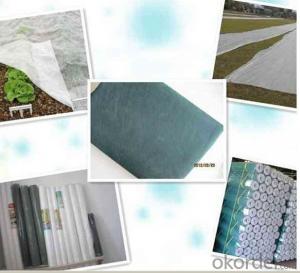

Beige PP Spunbonded Nonwoven Geotextile Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Beige PP Spunbonded Nonwoven Fabricis used to protect the crops in agriculture UV resistance masterbatch could be added 1%~8%. It can protect the vegetable crops and new lawns against extreme weather, animal and insect damage, yet allows light, water and air to penetrate, creating protected growing conditions..

Specification of Beige PP Spunbonded Nonwoven Fabric:

Width : From 1~ 2.4m

Length: 50-100m as customer requests.

Weight : 17gsm~ 80gsm

Color : black ,white ,other colors are available

Packing of Beige PP Spunbonded Nonwoven Fabric

Each roll is wrapped in a plastic bag with label specification with paper tube inside .

Superiority

1.Free Samples

2.Factory Supply

3.Competitive Price With High Quality

4.More than 20 years experience

- Q: How do geotextiles help with sediment control?

- Geotextiles help with sediment control by acting as a barrier that prevents sediment from being washed away or eroded. They stabilize the soil, reduce erosion, and allow water to pass through while trapping sediment particles, thus preventing them from contaminating water bodies.

- Q: What are the standards and regulations for geotextile products?

- The standards and regulations for geotextile products vary depending on the country and region. However, there are several widely recognized international standards that govern the manufacturing, testing, and performance requirements of geotextiles. These include standards from organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards cover aspects such as strength, durability, permeability, and environmental compatibility. Additionally, various regulatory bodies may have specific requirements for geotextile products, particularly in the construction industry, to ensure their safe and effective use in specific applications.

- Q: Garden engineering. Do the roof of the hydrophobic board and geotextile roof, would like to know the hydrophobic board and geotextile "sub-project name" and "hidden project"

- Yue Jian professional production geotextile Wang Bin

- Q: How do geotextiles help in preventing soil contamination?

- Geotextiles help in preventing soil contamination by acting as a barrier that prevents pollutants and contaminants from infiltrating into the soil. They are designed to have high permeability, allowing water to pass through while trapping sediments and pollutants. This helps in reducing the risk of contaminant migration, protecting the underlying soil and groundwater from pollution. Additionally, geotextiles also enhance soil stability and drainage, further minimizing the potential for soil contamination.

- Q: Can geotextiles be used in mining and landfill closure applications?

- Yes, geotextiles can be used in mining and landfill closure applications. Geotextiles are commonly used in these applications to provide erosion control, soil stabilization, and filtration. They act as a barrier to prevent soil erosion and help in containing mine waste or landfill materials. Additionally, geotextiles can improve the overall efficiency and safety of these operations by reducing the risk of environmental contamination.

- Q: Fish pond geotextile use method

- HDPE geomembrane can be used to do impermeable, I professional production

- Q: Can geotextiles be used in landfill applications?

- Yes, geotextiles can be used in landfill applications. They are commonly used as part of the liner system in landfills to separate and stabilize different layers of soil and prevent the migration of contaminants. Geotextiles help enhance the overall performance and environmental protection of landfills by promoting proper drainage and reducing the potential for erosion.

- Q: How do geotextiles help with soil erosion on slopes?

- Geotextiles help with soil erosion on slopes by acting as a protective barrier between the soil and the forces that cause erosion. They stabilize the soil, prevent its displacement, and enhance its strength. Geotextiles also promote water filtration and drainage, reducing the risk of water-induced erosion.

- Q: Geotextile moisture-proof layer: 200 cloth +400 film +200 cloth

- Two cloth a film manufacturers direct production qualification need to contact

- Q: Permeable geotextile price how much

- 2 to 4 yuan range

Send your message to us

Beige PP Spunbonded Nonwoven Geotextile Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords