PP Spunbonded Non-woven Fabric with Different Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PP Spunbonded Non Woven Fabric Introduction

Color: White,blue,green,pink,black or as customized

Material: 100% Polypropylene

Type: Spunbond Nonwoven Fabric

Width: Maximum width 240cm (can be slit)

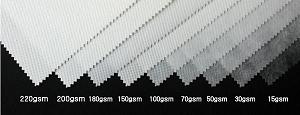

Weight: 9-200gsm

Characteristics: High quality, Stable uniformity, Adequate Weight; Soft Feeling, Eco Friendly, Recycleable, Breathable; Good Strength

Packing: Rolled with 3" paper tube inside and transparent PE bag and plastic film outside

Delivery time: 7-30 days against quantity

Payment term: TT or L/C

Application: Health, medical, industrial, household, agriculture

PP Spunbonded Non Woven Fabric Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

PP Spunbonded Non Woven Fabric After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Can geotextile skin be connected?

- Geotextile skin can be touched. Geotextile production of raw materials is polyester fiber, polyester has been widely used in daily life. Such as clothes are also a lot of polyester material. So do not worry, geotextile is not harmful to the human body.

- Q: Geotextile Commission test how many square meters

- 1-2 square meters, I am specializing in the production of geotechnical materials

- Q: What is the difference between geotextile and impervious geotextile, geotextile and impervious geotextile?

- Geotextile is permeable, and water, but the soil, from the filter effect, impermeable geotextile is geomembrane composite geotextile composite products, is impermeable and waterproof, I am specializing in the production of geotechnical materials,

- Q: How do geotextiles help in preventing erosion around culverts?

- Geotextiles help in preventing erosion around culverts by providing a protective barrier against soil movement and water flow. They are placed around the culvert to stabilize the soil and prevent it from washing away during heavy rains or water flow. The geotextiles act as a filter, allowing water to pass through while effectively preventing soil particles from being carried away. This helps maintain the integrity and stability of the culvert structure, preventing erosion and ensuring long-term functionality.

- Q: How do geotextiles help with reinforcement of steep slopes?

- Geotextiles help with the reinforcement of steep slopes by providing stability and preventing erosion. They are often used as a reinforcement material to increase the shear strength of the slope and improve its overall stability. Geotextiles help distribute the load across the slope, reducing the risk of landslides or slope failure. Additionally, they allow for effective drainage, preventing the accumulation of water behind the slope, which can further weaken it.

- Q: How do geotextiles contribute to groundwater recharge projects?

- Geotextiles contribute to groundwater recharge projects by acting as a filtration and drainage system. They allow water to pass through while retaining sediment, preventing clogging of the recharge basins or infiltration trenches. This helps to enhance the recharge process, allowing more water to percolate into the ground and replenish the groundwater.

- Q: Geotextile 500 grams is what it means

- 500g per square meter of quality, I professional production geotextile geomembrane, wish smooth

- Q: How do geotextiles contribute to groundwater recharge?

- Geotextiles can contribute to groundwater recharge by acting as a filtration system, allowing water to pass through while preventing the movement of soil particles. This helps to prevent the clogging of recharge basins or infiltration trenches, ensuring a more efficient recharge of groundwater.

- Q: What are the different geotextile installation techniques for steep slopes?

- There are several geotextile installation techniques that can be used for steep slopes. Some of the common techniques include slope stabilization with geotextile mats or grids, slope reinforcement with geotextile wraps or anchors, and soil erosion control with geotextile blankets or erosion control mats. Each technique is chosen based on the specific requirements of the slope and the desired outcome.

- Q: Geotextile need to adjust the humidity before sampling, what does this mean

- probably. For the first time I heard that geotextiles were sampled to be wet.

Send your message to us

PP Spunbonded Non-woven Fabric with Different Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords