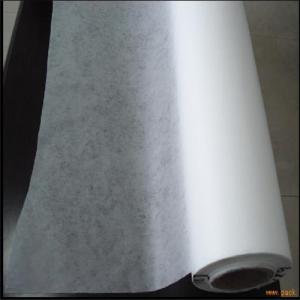

Northwest Linings and Geotextile PP Spunbonded Nonwoven Fabric in Different Colors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of polypropylene spunbond non woven fleece fabric is used to protect the crops in agriculture UV resistance masterbatch could be added 1%~8%. It can protect the vegetable crops and new lawns against extreme weather, animal and insect damage, yet allows light, water and air to penetrate, creating protected growing conditions..

Specification of Polypropylene Spunbond Non Woven Fabric:

Width : From 1~ 2.4m

Length: 50-100m as customer requests.

Weight : 17gsm~ 80gsm

Color : black ,white ,other colors are available

Packing of Polypropylene Spunbond Non Woven Fabric:

Each roll is wrapped in a plastic bag with label specification with paper tube inside .

FAQ :

1.What is your main products ?

Our main products are made from PE ,PP etc and could be used for agriculture and construction ,etc .

2.What is your payment term ?

We could accept TT ,LC.

3.What is your delivery time ?

The delivery time is around 30days per container, sometimes we have stocks .

pp spunbonded nonwoven fabric

- Q: Can geotextiles be used for separation of different soil layers?

- Yes, geotextiles can be used for the separation of different soil layers. Geotextiles act as a barrier between different soil layers, preventing their mixing and maintaining their individual characteristics. This helps to enhance soil stability and prevent the loss of fine particles, ensuring the long-term performance of structures built on or with different soil layers.

- Q: How are geotextiles affected by moisture content?

- Geotextiles can be affected by moisture content in several ways. When exposed to excessive moisture, geotextiles can lose their strength and integrity, leading to reduced performance and functionality. Excessive moisture can also cause geotextiles to become clogged or blocked, affecting their ability to drain water and maintain their permeability. Additionally, moisture content can impact the durability and lifespan of geotextiles, as it can contribute to the growth of microorganisms that can degrade the material. Therefore, it is crucial to consider moisture management when using geotextiles in various applications.

- Q: Characteristics of nonwoven geotextiles

- Non-woven geotextile has many advantages: 1) air permeability 2) filterability 3) insulation 4) water absorption 5) waterproof 6) stretch 7) not disheveled 8) feel good, soft 9) light 10) Can be restored 11) without the direction of the fabric 12) compared with the textile production of high productivity, production speed 13) low prices, can be mass production and so on. Disadvantages are: 1) Compared with the textile fabric strength and durability is poor; 2) can not be washed as other fabrics; 3) fiber arranged in a certain direction, so easy to split from the right angle and so on. Therefore, the improvement of the production method has been mainly focused on preventing the improvement of the division.

- Q: Can geotextiles be used for reinforcement in embankment construction?

- Yes, geotextiles can be used for reinforcement in embankment construction. Geotextiles are often used as a cost-effective solution to enhance the stability, strength, and durability of embankments. They can provide soil confinement, prevent erosion, and improve the overall performance of the embankment by distributing loads and reducing settlement.

- Q: Will the HDPE geomembrane, non-woven geotextile re-examination to detect what project? Is there a basis for testing? Thank you, hurry! The The

- CBR top breaking strength, vertical permeability coefficient ,,

- Q: What are the considerations for geotextile selection in shoreline erosion control?

- When selecting geotextiles for shoreline erosion control, several considerations need to be taken into account. These include the strength and durability of the geotextile, its resistance to UV degradation and chemical exposure, its permeability to allow for proper drainage, and its ability to retain sediment while still allowing for plant growth. Additionally, factors such as cost-effectiveness, installation requirements, and the specific environmental conditions of the shoreline should also be considered in the selection process.

- Q: What are the advantages of using geotextiles in soil erosion prevention?

- Geotextiles offer several advantages in soil erosion prevention, including increased soil stability, improved drainage, and enhanced filtration. These synthetic materials can effectively reinforce soil, preventing its movement and erosion. Geotextiles also allow water to pass through while trapping sediment, reducing the risk of erosion and maintaining the integrity of the soil. Additionally, they are easy to install and cost-effective, making them a practical solution for erosion control in various applications.

- Q: How is the strength of geotextiles determined?

- The strength of geotextiles is typically determined through laboratory testing, which involves assessing various mechanical properties such as tensile strength, puncture resistance, and tear strength. These tests help evaluate the geotextile's ability to withstand different loads and stresses, ensuring its suitability for specific engineering applications.

- Q: How do geotextiles help with load transfer in foundation systems?

- Geotextiles help with load transfer in foundation systems by providing a stable and uniform platform for distributing the load from the structure to the underlying soil. They act as a separator, preventing the mixing of different soil layers and reducing the risk of differential settlement. The geotextiles also enhance the soil's strength and stability, thereby improving the overall load-bearing capacity of the foundation system.

- Q: What are the different geotextile installation techniques in separation?

- The different geotextile installation techniques in separation include direct placement, trench installation, and overlay installation. Direct placement involves laying the geotextile directly on the subgrade or soil surface, providing separation between different layers of soil or aggregate. Trench installation involves placing the geotextile in a trench dug along the separation line, then backfilling the trench with soil or aggregate. This technique is commonly used in applications like road construction. Overlay installation involves placing the geotextile on top of an existing surface, such as an old road, to provide separation between the existing surface and a new layer of soil or aggregate. Each installation technique has its advantages and is chosen based on the specific project requirements.

Send your message to us

Northwest Linings and Geotextile PP Spunbonded Nonwoven Fabric in Different Colors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords