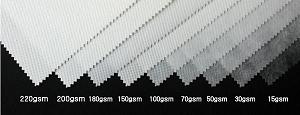

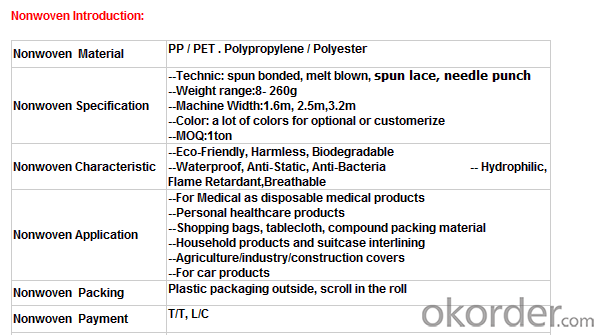

PP Spunbonded Colored Nonwoven Fabric for Suit and Garment Covers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q: Textile industry after finishing what pollution, especially air pollution

- Hello I am a person engaged in the field of environmental science sewage remediation industry a year first said that the current government sewage on the enterprise requirements for the main COD and ammonia nitrogen because the two will cause serious harm to the river

- Q: How can paint points be removed during textile processing?

- So, if it is a slight, a small amount of paint points, you can use butyl acetate rubbed, and then through the conventional pre-treatment process to remove it

- Q: Classification of textile materials

- The yarn is composed of fiber, with pure spinning yarn, blended yarn, with yarn distribution; according to the distribution of mixed fiber, there are evenly mixed yarn, change the mixed yarn, combination or composite yarn points

- Q: How to make fibrous textiles for waste plastic bottles?

- Plastic bottle is a treasure, you can also make quilts, sofas, mattresses and other home textiles fillers, can also be used to make carpets, imitation and down products

- Q: Are hats a class of textile and apparel products?

- All year round seems to generally only winter hat, hat should belong to the textile and apparel products bar. Jewelery is available all year round.

- Q: Antistatic fabrics of textile electrostatic materials

- Clothing charged, a large number of adsorption of dust, easy to contaminate, and clothing and the human body, clothing and clothing will occur entanglement phenomenon or produce spark. Therefore, the electrostatic interference, affecting the smooth progress of processing, affecting the quality of the product and the performance of the fabric, etc.

- Q: Textile finishing TPU, TPEF film. What's the difference?

- High mechanical strength. TPU products carrying capacity, impact resistance and shock absorption performance. TPU

- Q: The Factors Affecting the Capillary Effect of Textile Garment

- The degree of removal of the pulp; the amount of impurities in the wax itself, pectin and other impurities

- Q: China textile products do not how points? What kind of?

- Scale, distribution tends to focus. Jiangsu Province as a full range of fiber Dasheng fabric Dasheng clothing province, clothing annual output, sales, profits are among the forefront of the country

- Q: What causes the loss of textile enterprises

- Raw material costs rise, seasonal strong, large inventories, small businesses prone to cash flow difficulties, and now the financial crisis, capital is scarce resources

Send your message to us

PP Spunbonded Colored Nonwoven Fabric for Suit and Garment Covers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches