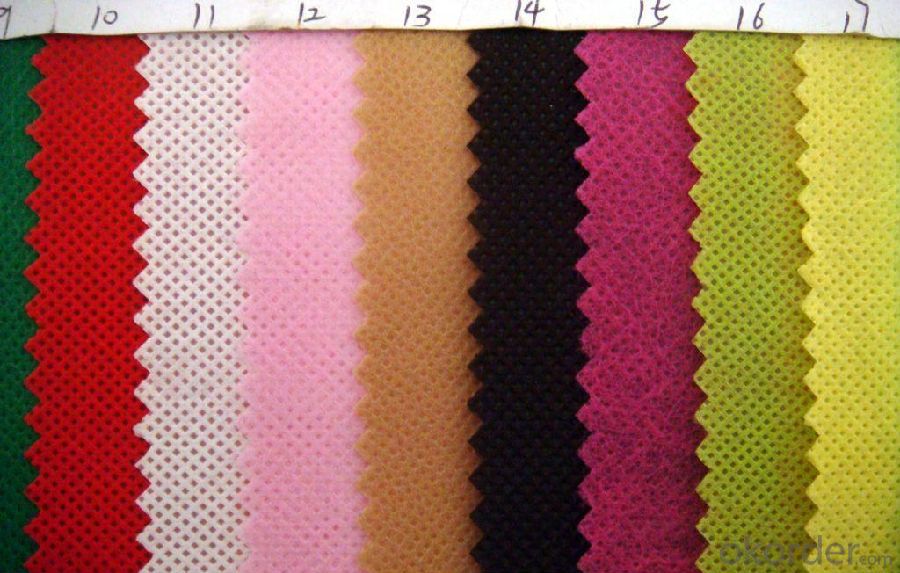

PP Spunbond Printed Non-woven Fabric Customized Beautiful Vivid Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

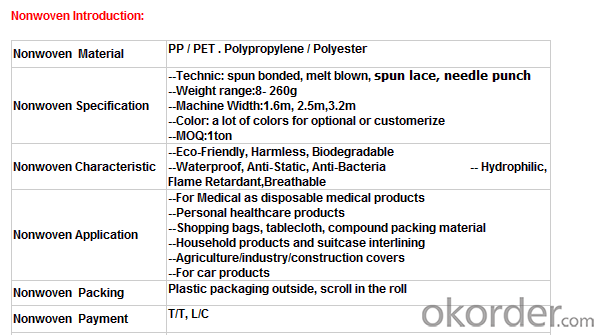

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q: Textile industry after finishing what pollution, especially air pollution

- At least chronic poisoning for humans and animals is usually the government in order to create achievements or to meet the personal interests of individual officials will be so because of chronic poisoning, after all, there are three or five years or even 30 years of concealment proposed to the Provincial Environmental Protection Office to call complaints or petition

- Q: The weight of the textile fabric

- Fabric cost = raw material cost + weaving costs + dyeing after finishing processing fees + test volume packaging costs + tax + loss of all links

- Q: Textile raw materials of mineral fiber

- The main ingredient is inorganic, also known as natural inorganic fibers, inorganic metal silicates, such as asbestos fibers.

- Q: What is the amount of alkali in the textile mill

- Made with polyester woven cloth, not suitable for personal wear. Through the printing and dyeing plant in a process called reduction processing, the polyester cloth in a large concentration of caustic soda solution containing corrosion treatment, the total weight of polyester cloth

- Q: What is the number of raw materials for textile enterprises?

- General varieties are used, PVA, modified starch and other main pulp, plus propylene and wax tablets and other additives,

- Q: Textile finishing TPU, TPEF film. What's the difference?

- High mechanical strength. TPU products carrying capacity, impact resistance and shock absorption performance. TPU

- Q: What are the invoices for the textile industry?

- If you are the general taxpayer of the trade sales type, the finished textile fabric purchased is the incoming invoice

- Q: "Textile color standard system"

- The dye molecules and heavy metal ions are likely to be absorbed by the skin and endanger the health of human skin, on the other hand will affect the other clothing worn on the body was stained, or with other clothes when washing dirty other clothing The

- Q: What is the difference between the mesh pattern on the textile structure?

- Disadvantages and polyester, like moisture and poor ventilation. Acrylic, features: polish than wool, silk fiber is good. But poor wear resistance. There are also vinylon, polypropylene, spandex and so on

- Q: Why is cotton textiles shrinking?

- In the immersion of water, the water will make the fiber molecules between the contact gradually weakened, the fiber surface friction decreased, so that the temporary "stable" state is destroyed, the fiber will be restored or close to the original balance

Send your message to us

PP Spunbond Printed Non-woven Fabric Customized Beautiful Vivid Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches