PP/PE/PVC Single Wall Corrugated Conduit Pipe Extrusion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

The production line is mainly used in the production of PVC pipe,The producing line can be adjusted according to clients' requirements .

What's more, the line can work at high capacity and be easy to maintain.

Nomally this line is composed by eight parts ,as follow:

1. Feeder

2. conical twin-screw extruder

3. pipe mould

4. vacuum calibration tank

5. Spraying box

6. haul-off

7. cutter

8. staker

The mixer can also be equiped by requirement .

Machine Application

Such qualified extrusion line is mainly for producing PVC agricultural water/ building water/cable pipes, etc.

It can process various soft and rigid PVC, especially process powder directly into pipe shape.

Whole line consists of material feeder, conical twin screw extruder, die head, vacuum calibration tank, haul-off, cutter, stacker or belling machine, etc.

Machine List

| No. | Item | Qty |

| 1 | Screw feeder | 1 set |

| 2 | SJZ 80/156 Conical twin screw extruder | 1 set |

| 3 | Die head | 1 set |

| 4 | Vacuum calibration tank | 1 set |

| 5 | Three claws haul-off | 1 set |

| 6 | Planetary cutter | 1 set |

| 7 | Stacker | 1 set |

| Option | Belling Machine | 1 set |

Annotation: Some configuration and material can be designed according to customers’ requirement. | ||

Outstanding features

Extruder: adopting conical twin-screw extruder, unique designed screw, realizing shorting plasticizing time, good compounding and excellent plasticization.

Gearbox: adopting super quality gear box and reducer, with nice outline, stable running, low noise and long service time.

Extruding barrel temperature controlling system: adopting cast aluminum heaters with stainless steel covers, wind cooling system, ensuring good features of cooling and heating, precision temperature controlling.

Screw and barrel: screw-core installing with internal temperature controlling system, barrel equipped with vacuum degassing system, can get rid of the waste gas from the raw material which can guarantee super quality of the products.

Driving system: adopting A.C motor, using FUJI or ABB inverters which provide stable torque output and various speed.

Vacuum calibrating tank: with two vacuum chambers which can make sure the perfect roundness of the pipe, spraying water cooling, equipped with temperature controller, realizing automatic discharging the water, the main body of the tank make of stainless steel, long service time.

Haul-off machines: 2 laws, 3 claws, 4 claws, 6 claws and 8 claws are provided to manufacture various pipes, haul-off speed governed by the FUJI or ABB inverter.

Cutting unit: saw cutting and planet saw cutting, with dust collection system.

Staking unit: automatic overturning system, can freely fix the length of the pipe.

Controlling system: manual controlling cabinet or SIEMENS PLC touch screen controlling

Our Services

The Advanced Processing Line

A. Fixed Equipments for Q/C

B. Professional team of Q/C

C. Qualified successfully before get in warehouse

D. Checking Machines before shipment

Before sales

1.Introduce products and application details

2.Recommend suitable solutions

3.Provid with reference information

During manufaturing

1.Provid with layout and engineering conditions

2.Inform the processing conditions

3.Offer other documents

After Sales

1.Provid with installation and trainning

2.Offer spare parts

3.Provid with neccesary technical support

Technical Data

Extruder | Pipe ranger (mm) | Max.output (kg/h) | Max.hauling speed (m/min.) | Extruder powder (KW) |

CAMX51/105 | 16-40 Dual | 120 | 10 | 18.5AC |

CAMX65/132 | 20-63 Dual | 250 | 15 | 37AC |

CAMX51/105 | 20-63 | 120 | 15 | 18.5AC |

CAMX65/132 | 50-160 | 250 | 8 | 37AC |

CAMX65/132 | 63-200 | 250 | 3.5 | 37AC |

CAMX80/156 | 160-315 | 350 | 3 | 55AC |

CAMX92/188 | 315-630 | 800 | 1.2 | 110DC |

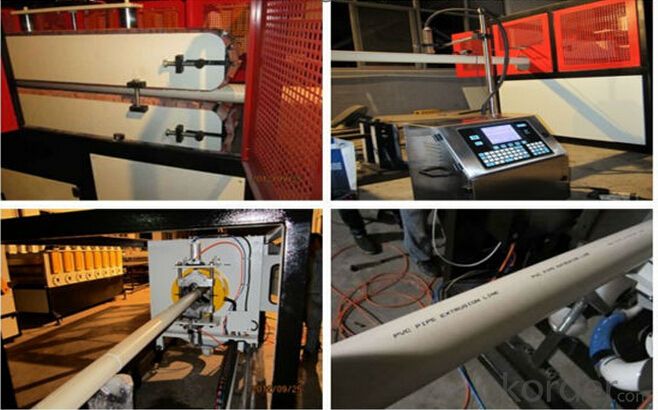

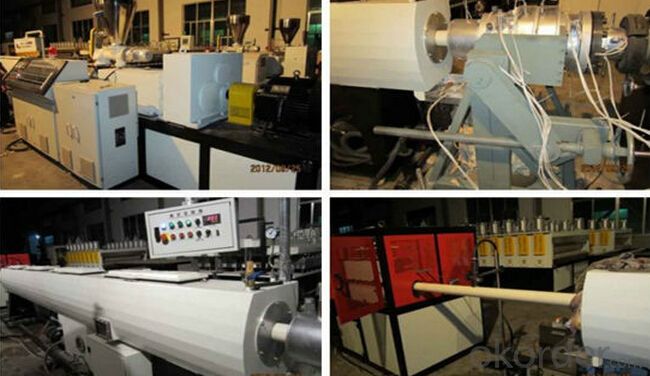

Product picture

FAQ:

Q: What price terms you offer?

A: FOB, CIF, EXW, L/C at sight and other price terms based on your kind request.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A : Our factory is in Tangqiao Town, Zhangjiagang City, Jiangsu Province, China. About 2.5 hours from Shanghai Pudong International Ariport! We will arrange to pick you up from Shanghai.

A: Yes, our engineers will guide machine installation and train your workers.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- As far as actual production is concerned, it is necessary to go beyond the regulations to produce normally

- Q: What are the common extrusion molding products?

- Extrusion molding products are as follows:1 、 plastic pipe, for example: water pipe up and down;2, plastic profiles, such as: doors and windows, plastic steel profiles.3, plastic plates, such as: wood plastic doors, plastic doors,4, plastic sheet (sheet and board is the difference between the thickness, thin, thick plate), such as: mobile phone membrane.

- Q: Why do screw extruders often extrude light red plastic products?

- You should have before the production of red raw material hopper or hopper and barrel, or between the screw shank and barrel etc. the raw material residue, not clean, often with extrusion part. Cause this situation. Please clean the hopper thoroughly. The screw is also drawn out and cleaned up. It should be easy to solve.

- Q: Why can the plastic extrusion machine extrude the flat bar?

- What's the reason for pulling out the stripes?1, the vacuum is not enough.2, high temperature settings.3, formula lubrication is too much

- Q: Comparison of injection molding machines and Extruders

- The plastic to replace steel or nonferrous metal, plastic cement, which is widely used in agriculture, building materials, packaging, machinery, electronics, automobiles, household appliances, petrochemical and defense, extruder and daily life other fields. So it can be predicted that in twenty-first Century, the plastic will be one of the most important raw material of human activities. The extruder design due to extrusion molding is the main form of plastic processing, so the development of plastic extrusion molding technology and equipment has important significance. The polymer materials used in blending type mixing equipment modification there are three main types: parallelwith twin-screw extruder, reciprocating screw kneader and series disc extruder. The small corotating twin screw extruder has domestic production can squeeze But tons of large mixing extrusion granulation unit will rely on the import machine technology. At the same time. Reciprocating screw kneader and series disc extruder is a necessary device for preparing high fill and high added value of polymer alloy, the current domestic research on them is just in the prototype stage, specifications, varieties not all, have broad prospects for development.

- Q: PLC based extrusion machine control system design graduation thesis and PLC based injection molding machine control system thesis content?

- I can help you with this design.Select the topic according to the academic direction. The key to the value of thesis writing lies in the ability to solve specific problems in a particular industry, especially in academic terms. Therefore, one of the techniques for selecting and refining titles is to select and refine them according to their academic value.

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- How big is it? Not too big. I suggest using a 40 or 30 too big block. You have to use a special break knot. There is a kind of broken engineering material. I wonder if you can find it

- Q: why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- Plastic tensile testing without tension is strong that said, you should be the low tensile strength, tensile strength for 2 kinds of films, one is the transverse tensile strength, a longitudinal tensile strength, is a reflection of the tensile properties, the tensile strength of the plastic bag if you low, because your choice of materials is not brittle material or toughness (PE/PP/PVC/PET/PBT/PC do not know or what material) if you insist on using this material, make plastic bags, you can modification method by crosslinking, adding additives, improving formula, to achieve the goal, the specific situation you need to find a degree in Polymer Science plastic engineer, they will tell you.

- Q: What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

Send your message to us

PP/PE/PVC Single Wall Corrugated Conduit Pipe Extrusion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches