Special Use Single Wall and Double-wall Corrugated Pipe Plastic Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | PP film winding and then to the wooden box |

| Delivery Detail: | 30 days after confirming the deposit |

corrugated pipe extrusion line

Application

Mini single wall high speed corrugated pipe forming machine: Can produce two diameters or three diameters

single wall corrugated pipe in the same mould blocks, which reduce the cost of the mould blocks and reduce

the time for changing the mould blocks, increase the efficiency.

Advantage: The pipe from this machine is anti-high temperature, anti-wear, and high strength, and it is

widely used in electrical conduct, car conduct pipe, protective pipe, machine area and automatic meter area.

With Jwell special design screw and advanced mould, the line is high speed, run stable and easy-control.

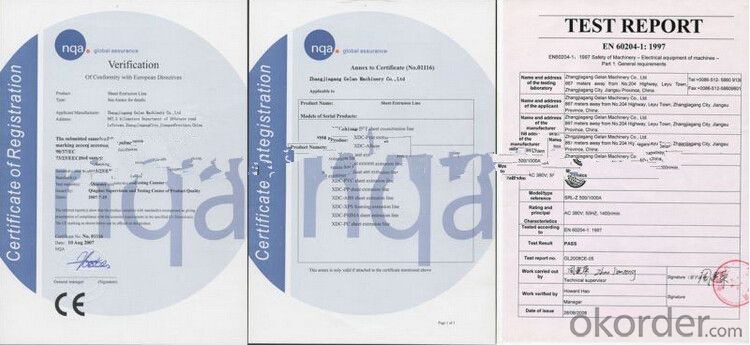

Certification:

- Q: Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Cable extruder type 657090 machine, describes the diameter of the screw, the unit is mm.The greater the number, the greater the equipment, the greater the amount of gumIt is usually marked on the control cabinet of the equipment

- Q: Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q: What is the adjustment method of China's extrusion machine die?

- (5) sense of mold: it is the method of experience versus mold. Feel the thickness of the plastic layer by hand and adjust the mold. The utility model is suitable for the outer protective layer of large cross section wire and cable.

- Q: Why can the plastic extrusion machine extrude the flat bar?

- What's the reason for pulling out the stripes?1, the vacuum is not enough.2, high temperature settings.3, formula lubrication is too much

- Q: Comparison of injection molding machines and Extruders

- The plastic to replace steel or nonferrous metal, plastic cement, which is widely used in agriculture, building materials, packaging, machinery, electronics, automobiles, household appliances, petrochemical and defense, extruder and daily life other fields. So it can be predicted that in twenty-first Century, the plastic will be one of the most important raw material of human activities. The extruder design due to extrusion molding is the main form of plastic processing, so the development of plastic extrusion molding technology and equipment has important significance. The polymer materials used in blending type mixing equipment modification there are three main types: parallelwith twin-screw extruder, reciprocating screw kneader and series disc extruder. The small corotating twin screw extruder has domestic production can squeeze But tons of large mixing extrusion granulation unit will rely on the import machine technology. At the same time. Reciprocating screw kneader and series disc extruder is a necessary device for preparing high fill and high added value of polymer alloy, the current domestic research on them is just in the prototype stage, specifications, varieties not all, have broad prospects for development.

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat, because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q: There is a 90 extrusion machine, used in the production of communication cables (outside the cable core is extruded with a layer of LLDPE), now is the configuration of Y2-280M-490KW167A inverter type ACS510197A + ABB), General Motors now found low speed when the current is too large, what reason? How to solve? The details are as follows: used for communication cable production HYA30*2*0.4, 1, line speed is 50 m / min, inverter display frequency 35.3HZ current: 116A; 2, line speed is 40 m / min, inverter display frequency of 28.2hz, current: 140A3, line speed is 35 m / min, the frequency converter significantly method: 157A 24.6HZ frequency current, because the product variety and technical reasons, we need to be in the frequency of 10HZ production. Now, it seems that if I reduce the speed again, the current will probably exceed the rated current. What should I do? Is the motor changed to frequency conversion motor? Or inverter? How to solve? Please heroes pointing, thank you!

- See the ACS510 manual, this type of inverter used in fan pump type, 2605 control methods of determining its U/F, the default value is 2 (the square type, namely fan pump type); for constant torque load, should be set to 1 (linear). When not available, does the debugger not modify the parameter to 1? If that's the case, will the top floor say what happened?

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- Extrusion molding in plastic processing is called extrusion, using hydraulic pressure in rubber extruder processing in extrusion die extrusion. That itself means that the material through the extruder barrel and screw the function between the side heating plasticization, screw edge is pushed forward, a processing method of continuous head made by various sections of finished or semi-finished products.In the fiber chemical industry is also useful in the extruder to the spinneret for melt spinning. The material, process of extrusion used in thermoplastic plastics and rubber, for batching, granulation, rubber filtration, continuous production, manufacturing various continuous products such as pipe, profile, sheet (or sheets), thin film wire and cable coating, rubber tire, tube noodles barrel, a sealing strip, the production efficiency is high. In the production of synthetic resin, can be used as reactor extruder, continuous polymerization and processing, in rubber industry, the compression ratio of different extruding machine can be used to unmasticated natural rubber of different materials. Compression extrusion machine than some different. [edit this paragraph] the principle of extrusion molding material since the bucket into the barrel, the screw rotates under the action of the cylinder wall and the surface of the screw friction shearing forward delivery to the feeding section in the loose. Forward transport also is compacted; the compression section, screw groove depth, further compaction, while the barrel heating and screw and cylinder wall friction shear, the material temperature rise began to melt, the compression section ends; homogeneous section material uniform, constant temperature, fixed quantity, squeeze out to melt. After a head forming, by setting the product.

Send your message to us

Special Use Single Wall and Double-wall Corrugated Pipe Plastic Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords