Special Use Single Wall and Double-wall Corrugated Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | PP film winding and then to the wooden box |

| Delivery Detail: | 30 days after confirming the deposit |

corrugated pipe extrusion line

Application

Mini single wall high speed corrugated pipe forming machine: Can produce two diameters or three diameters

single wall corrugated pipe in the same mould blocks, which reduce the cost of the mould blocks and reduce

the time for changing the mould blocks, increase the efficiency.

Advantage: The pipe from this machine is anti-high temperature, anti-wear, and high strength, and it is

widely used in electrical conduct, car conduct pipe, protective pipe, machine area and automatic meter area.

With Jwell special design screw and advanced mould, the line is high speed, run stable and easy-control.

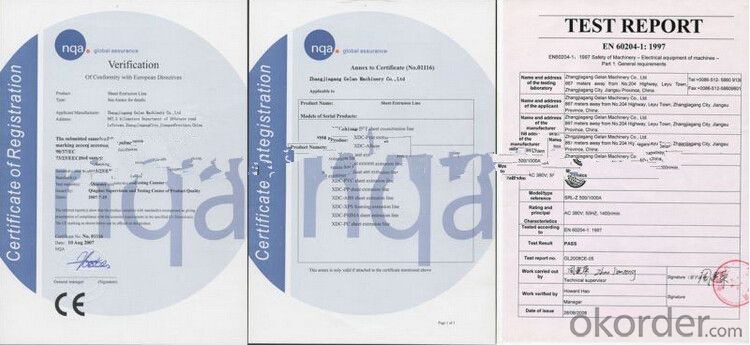

Certification:

- Q: when I use armature voltage feedback (host start speed 50, normal can produce 10It is normal to start at 80 or 150 of the speed, but after a few minutes the motor does not turn. 590 alarm (missing pulse alarm). When I change the feedback mode to speed feedback, my host sometimes starts and sometimes fails to start. I hope you help me, how should I adjust?. Thank you。

- I've also encountered (missing a pulse alarm), and finally checked out is a SCR triggered, impassability, you can try

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Plastic is a chemical product, and the waste gas produced by the process is organic waste gas. The commonly used and relatively efficient treatment method is activated carbon adsorption. The specific work process is as follows: exhaust gas, air pipe, dry filter, activated carbon adsorption, fan and discharge

- Q: For example, 70 square conductors, the outer diameter is A, out of the insulation, then the line mouth to choose how much, how much plastic cover election? Then the sheath, then how to choose the mold?

- Depending on your specific specifications, if XLPE is insulated, extrusion die with small touch line, set on the use of cable diameter, large core conductor than a few tenths of good, if you like to use 70 square tube extruding mold insulation of the conductor element some is big 1 can be set according to the touch, the tensile ratio calculation, PVC1.6 DYWL material with smaller good-looking it is simple of the extrusion process

- Q: Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Screw diameterAskDo you mean the plastic screw? 90 machines are so long. What's the 90 machine? Thank youChasing the answerDiameter, not length

- Q: Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q: What are the common extrusion molding products?

- Extrusion molding products are as follows:1 、 plastic pipe, for example: water pipe up and down;2, plastic profiles, such as: doors and windows, plastic steel profiles.3, plastic plates, such as: wood plastic doors, plastic doors,4, plastic sheet (sheet and board is the difference between the thickness, thin, thick plate), such as: mobile phone membrane.

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 1: extruder, is threaded through the push rod, the plastic die forming process by melting in the forward process. After the extruder products are silk, belt, tube, plate, etc. 2: injection molding machine, mainly to melt the plastic injection molding process, after the mold injection molding machine outjection. The main products are mechanical parts, containers, household appliances shell.

- Q: Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- Proposed Delta VFD-cp Series ~!AskCP2000 is constant pressure water supply... Are you sure you can use it? And C2000 is better than qualifiedChasing the answerWrong number ~ ~ should be C2000, and VE Series ~ ~ these two are suitable, ~~B, CP is not good ~!

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- Plastic tensile testing without tension is strong that said, you should be the low tensile strength, tensile strength for 2 kinds of films, one is the transverse tensile strength, a longitudinal tensile strength, is a reflection of the tensile properties, the tensile strength of the plastic bag if you low, because your choice of materials is not brittle material or toughness (PE/PP/PVC/PET/PBT/PC do not know or what material) if you insist on using this material, make plastic bags, you can modification method by crosslinking, adding additives, improving formula, to achieve the goal, the specific situation you need to find a degree in Polymer Science plastic engineer, they will tell you.

Send your message to us

Special Use Single Wall and Double-wall Corrugated Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches