PP Biaxial Geogrids for Tree Protection W*L3.95*50m/Roll for Soil Reinforcement and Civil Engineering Projects

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Biaxial Geogrid W*L3.95*50m/roll for Soil Reinforcement and Civil Engineering Project

1.Functions of Hot Sale High Quality PP Biaxial Geogrid 3.95*50m/roll for Soil Reinforcement

1)Strengthen the load capacity of roadbed or land base and extend the lifetime;

2)Can protect the road surface sinkage or crack;

3)Building convenience, save time and labour, shorten the time limit of project and reduce the charges of maintenance;

4)Can keep the culvert away from the crack;

5)Strengthen the land slope, keep the land away from running off.

6)Reduce the thickness of cushion, reduce the cost;

7)Support the grass to stability for land slope

2. Technical Sheet of Hot Sale High Quality PP Biaxial Geogrid 3.95*50m/roll for Soil Reinforcement

ITEM | TGSG25-25 | TGSG20-20 | TGSG30-30 | TGSG35-35 | TGSG40-40 |

WIDTH (M) | 3.95 or 4.0+/-0.2 | ||||

TENSILE STRENGTH (≥KN/m) IN LONGITUDIANAL | 25 | 20 | 30 | 35 | 40 |

TENSILE STRENGTH (≥KN/m) IN TRANSERSAL | 25 | 20 | 30 | 35 | 40 |

ELONGATION AT MAX STRAIN(≤%) IN LONGITUDIANAL | 15 | ||||

ELONGATION AT MAX STRAIN(≤%) IN TRANSERSAL | 13 | ||||

TENSILE STRENGTH AT 2% STRAIN(≥KN/m) IN LONGITUDIANAL | 8.75 | 7 | 10.5 | 12.50 | 14 |

TENSILE STRENGTH AT 2% STRAIN(≥KN/m) IN TRANSERSAL | 8.75 | 7 | 10.5 | 12.50 | 14 |

TENSILE STRENGTH AT 5% STRAIN(≥KN/m) IN LONGITUDIANAL | 17.50 | 14 | 21 | 25 | 28 |

TENSILE STRENGTH AT 5% STRAIN(≥KN/m) IN TRANSERSAL | 17.50 | 14 | 21 | 25 | 28 |

CARBON BLACK CONTENT | 2% | ||||

ROLL SIZE | 3.95*50M or 4*50m AS ONE ROLL | ||||

MESH SIZE | APPROX. 40*40MM | ||||

3. Application of Hot Sale High Quality PP Biaxial Geogrid 3.95*50m/roll for Soil Reinforcement

Highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

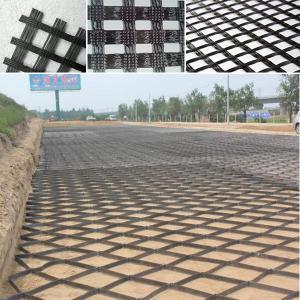

4. Product Show of Hot Sale High Quality PP Biaxial Geogrid 3.95*50m/roll for Soil Reinforcement

- Q: The tensile strength of a steel bar is about the number of cattle per square millimeter per square millimeter. The tensile strength of Gsa's cattle per meter, understand the carrying capacity of tensile Gsa every one meter in width is the number of cattle (considering Gsa gap), or single Gsa every one meter in length tensile capacity is the number of cattle (the size effect of Gsa does not consider the length direction). Please advise!

- Plastic mesh grille in custom-made case, first calculate the root number and the wire is thick, in the calculation of mesh size for tensile impact, your problem is that the tensile strength of steel grating is the tensile strength of each of the above. There are problems can be private chat, hope to adopt Thank you

- Q: Which is the most suitable for Highway Subgrade

- This depends on the Oh, you have no requirements on the design drawings, did not require the general steel plastic geogrid, plastic geogrid can be.

- Q: Is there a big difference between horizontal permeability and vertical permeability coefficient

- Geomembrane, composite geomembrane, geotextile, geogrid, geotextile, geotextile bags, etc. are called geosynthetics. The coefficient of permeability is a kind of soil properties;

- Q: Plastic two-way geogrid hole 4 cm thick, 1 mm wire width of 4 mm

- You say how many grams a square, or how many KN,

- Q: What is the recommended geogrid aperture size?

- The recommended geogrid aperture size depends on various factors such as the specific application, soil conditions, and engineering requirements. It is best to consult with a geotechnical engineer or a specialist in geogrid design to determine the appropriate aperture size for a particular project.

- Q: Are geogrids resistant to acid degradation?

- Yes, geogrids are generally resistant to acid degradation. They are commonly made from materials such as polypropylene or polyester which have excellent resistance to acidic environments. This resistance allows geogrids to maintain their structural integrity and performance even when exposed to acidic conditions.

- Q: Can geogrids be used in reinforced earth bridge abutments in liquefaction-prone areas?

- Yes, geogrids can be used in reinforced earth bridge abutments in liquefaction-prone areas. Geogrids are commonly used as reinforcement materials in geotechnical engineering to improve the stability and strength of soil structures. In liquefaction-prone areas where the soil may lose its strength and become unstable during seismic events, geogrids can provide additional support to the soil and prevent its failure. By incorporating geogrids into the reinforced earth bridge abutments, the overall stability and resilience of the structure can be enhanced, making it more resistant to liquefaction-induced damage.

- Q: Can geogrids be used in bridge abutments?

- Yes, geogrids can be used in bridge abutments. Geogrids are commonly used in soil stabilization and reinforcement applications, and they can be effectively used to improve the stability and strength of bridge abutments. By installing geogrids in the soil surrounding the abutments, the geogrids can distribute loads more evenly, prevent soil erosion, and provide additional support to the bridge structure.

- Q: Glass fiber grille modified asphalt, polyester grille coated PVC.

- This is the business secret of the production enterprise.

- Q: How to determine geogrid reinforcement or crack resistance

- Asphalt pavement cracking is one of the most common diseases in asphalt pavement in the world. No matter in the frozen area or in the non frozen area, the crack severity is different. The causes of asphalt pavement cracking and cracks in the form of a variety, but the main reason for the cracking of asphalt pavement, cracks can be divided into two categories, namely, the type of load cracks and non load cracks.The use of geotechnical materials to prevent asphalt pavement cracking effect is obvious. Selection of good resistance to erosion, dry shrinkage, temperature shrinkage coefficient is small, high tensile strength of semi-rigid material as the base, it is best to use the low temperature expansion coefficient of aggregate.High quality asphalt with good relaxation performance is used as the surface layer to ensure the penetration and ductility of asphalt. Certain additives or polymers should be used. In order to improve the low temperature crack resistance and high temperature stability of asphalt.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

PP Biaxial Geogrids for Tree Protection W*L3.95*50m/Roll for Soil Reinforcement and Civil Engineering Projects

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords