PP Biaxial Geogrid for Road Construction 15KN-50KN - Biaxial Geogrids Suppliers in USA

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial PP Geogrid,

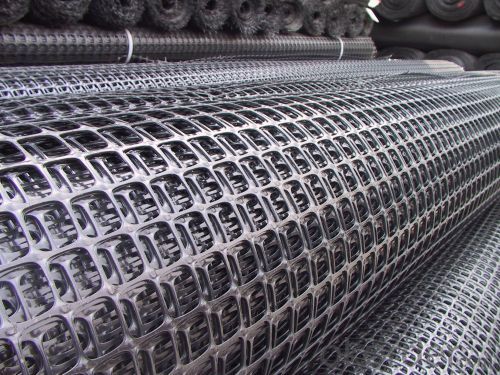

Biaxial geogrids are made of macromolecule polymer by the process of being stretched out, formed into lamella, punched regularly and then longitudinal and transverse elongated. They have much higher longitudinal and transverse tensile strength. These structures can supply alinking system to soil, which be used broadly to enable the permanent bearing capacity of roadbed.

Biaxial Geogrid Features:

1. high tension resistance.

2. high plane torsion resistance modulus.

3. good creep resistance and stable chemical nature.

4. high mechanic damage resistance.

5. reduce filling thickness, improve bearing capacity.

The main function as follows:

1.Reinforce the base, efficiently allot and diffuse the pressure, prolong the using time;

2.Increase the load-bearing capabilities;

3.Avoid the base becoming deformed and creaking (for the material washed away);

4.Improve the endure, reduce the pressure of the blocking wall, save the cost, prolong the using time, and reduce the servicing;

5.Reduce the crook and track, delay 3-9 times of the appearance of the crack, reduce 36% of the thickness of the structure by adding the geogrid into the base and cover of the road,

6.Be applicable of all kinds of soil;

7.Be easy to construct and reduce the cost.

FAQ:

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: What is the effect of moisture on geogrid performance?

- Moisture can have a significant impact on geogrid performance. When geogrids are exposed to moisture, they may experience reduced tensile strength and stiffness, as well as increased elongation and creep deformation. Moisture can also lead to the degradation of geogrid materials, especially if they are not resistant to chemical or biological attack. Additionally, moisture can affect the interaction between geogrids and the surrounding soil, potentially reducing their effectiveness in providing soil reinforcement or confinement. Therefore, it is important to consider and mitigate the effects of moisture when using geogrids in engineering applications.

- Q: How much is the double polypropylene plastic geogrid outsourcing testing fee?

- Hello ~ ~ ~ the general normal parameter detection in 600-800

- Q: What is the coefficient of friction of Nonwoven Geotextiles (polypropylene)?

- The biggest difference is that the geotextile with the membrane is impermeable and the nonwoven geotextile is permeable

- Q: How do geogrids improve the performance of mechanically stabilized slopes in clayey soils?

- Geogrids improve the performance of mechanically stabilized slopes in clayey soils by providing reinforcement and reducing the potential for slope failures. They enhance the tensile strength of the soil, increase its stability, and prevent excessive movement or deformation. This is achieved by distributing the applied loads more evenly throughout the slope, reducing the pressure on the clayey soil, and increasing its resistance to shearing forces.

- Q: What is the difference between geotextiles and geogrids?

- Engineering applications: highway, railway, bridge, road, pier, dam, slag field, such as soft soil foundation reinforcement, retaining wall and pavement crack resistance engineering and other fields. Glass fiber mesh used in exterior wall, interior wall paint, mainly to prevent cracking, different materials at the junction of mortar plastering material hollowing. Local node reinforcement will also be used. Geotextile has excellent filtration, drainage, isolation, reinforcement, seepage prevention, protection, light weight, high tensile strength, good permeability, high temperature resistance, anti freezing, anti-aging, corrosion resistance. Common non-wovenUsed in the water layer, polyethylene polypropylene fiber waterproof is also used.

- Q: How do geogrids improve the performance of geosynthetic filters?

- Geogrids improve the performance of geosynthetic filters by enhancing filtration efficiency and preventing soil erosion. They provide structural support, strengthening the overall system and distributing loads more evenly. Additionally, geogrids help in reducing the potential for clogging by preventing the migration of fine particles, thereby maintaining the long-term effectiveness of the filter.

- Q: Can geogrids withstand heavy loads?

- Yes, geogrids are designed to withstand heavy loads. They are commonly used in civil engineering and construction projects to reinforce soil and provide stability, even under significant weight or pressure. Geogrids have high tensile strength and durability, enabling them to effectively distribute and transfer loads, making them suitable for various applications such as roadways, retaining walls, and reinforced slopes.

- Q: Are geogrids suitable for use in soil reinforcement for bridge abutments?

- Yes, geogrids are suitable for use in soil reinforcement for bridge abutments. Geogrids offer a cost-effective solution to improve the strength and stability of soil, preventing erosion and settlement. They provide excellent tensile strength and interlocking capabilities to distribute loads, making them effective in reinforcing bridge abutments and enhancing their performance.

- Q: Are geogrids suitable for erosion control on riverbanks?

- Yes, geogrids are suitable for erosion control on riverbanks. Geogrids provide stabilization and reinforcement to the soil, preventing erosion and maintaining the integrity of the riverbank. They are effective in withstanding the forces of water flow and offer long-term stability, making them an ideal solution for erosion control on riverbanks.

- Q: How is a geogrid different from other geosynthetics?

- A geogrid is a type of geosynthetic that differs from other geosynthetics in its primary function and structural design. Unlike geotextiles or geocomposites that are primarily used for separation, filtration, or drainage purposes, geogrids are specifically designed to provide reinforcement and stabilization to soil and other materials. Geogrids are typically made of high-strength polymers and have a grid-like structure with open apertures, allowing them to interlock with soil particles and distribute loads more effectively. This unique design enables geogrids to enhance the mechanical properties of soils, increase their bearing capacity, and improve overall stability in various civil engineering applications.

Send your message to us

PP Biaxial Geogrid for Road Construction 15KN-50KN - Biaxial Geogrids Suppliers in USA

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords