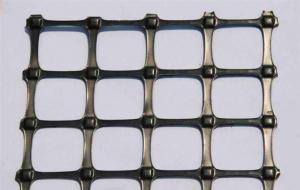

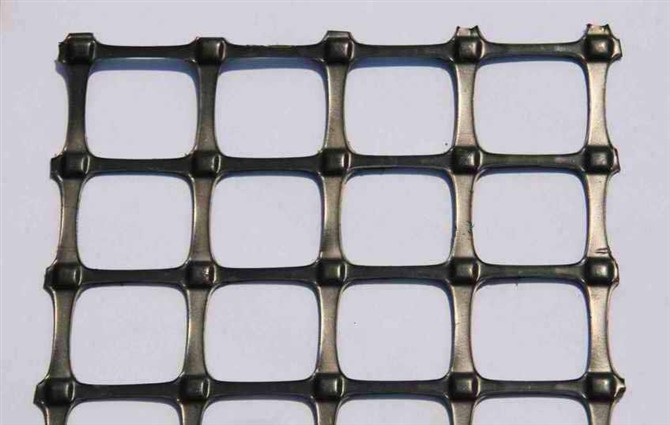

Titan Geogrids PP Biaxial Geogrid for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial Plastic Geogridfor Coal Mine road Railway highway

It is made from polymer and nanometer carbon black by extruded method .

Specification of Biaxial Plastic Geogrid for Coal Mine road Railway highway

L. Tensile strength (MD and TD)not less than 30kN/m

2. ROll width 2-4m, length as request

Property of BiaxialPlastic Geogrid for Coal Mine road Railway highway:

L. Not easy to produce static after friction. In the coal mine, surface staticresistance average is

Below lx109(LC

2. Good flame retardant performance, melt not burning under flam environment,even burning it

Will extinguish in lOs

3. Strong anti-corrosion property

4. High bearing capacity, low elongation

Application of Biaxial Plastic Geogrid for Coal Mineroad Railway highway:

Coal mine channels, more than 2 layers needed if for false roof use.

Production standard:

Q/LHX 02-2009

- Q: Can geogrids be used in mining operations?

- Yes, geogrids can be used in mining operations. Geogrids are commonly used in mining to reinforce soil and rock structures, provide stability to slopes and walls, and prevent erosion. They can also be used to improve the load-bearing capacity of roads and foundations, which is essential in mining operations.

- Q: Are geogrids suitable for use in agricultural applications?

- Yes, geogrids are suitable for use in agricultural applications. They can be used to strengthen soil and improve stability, reducing erosion and preventing soil compaction. Additionally, geogrids can enhance the performance of agricultural structures such as retaining walls, embankments, and roadways, making them a valuable tool in agricultural engineering.

- Q: What is the lowest price of two-way Plastic Geogrid

- General price to 25KN between 3.6-4.5, 30KN in about 5.5

- Q: Plastic grid plate making process

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. The plastic geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching, and it can be used as two kinds of uniaxial tension and biaxial tension. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length.

- Q: Can geogrids be used in shoreline erosion control?

- Yes, geogrids can be used in shoreline erosion control. Geogrids are synthetic materials that can reinforce and stabilize soil, preventing erosion. When properly installed, they can help to protect shorelines from the destructive forces of waves and currents, thereby reducing erosion and preserving the integrity of the shoreline.

- Q: Can geogrids be used in floating road construction?

- Yes, geogrids can be used in floating road construction. Geogrids are commonly employed in road construction projects to improve the stability and load-bearing capacity of the road structure. When used in floating road construction, geogrids help to distribute and reinforce the load, reducing the pressure on the underlying soil or subgrade. This ensures better performance and longevity of the road, even in challenging or soft soil conditions.

- Q: How thick is the need to lay a layer of Geogrid in the new highway earthwork backfill? Specific foundation to pave the way to solve

- You carefully look at the drawings, these drawings are illustrated.

- Q: What are the technical parameters and testing standards of the tensile creep testing machine

- Technical parameters: 1 180KN; the maximum load: 2 load accuracy: less than 1%; 3 fixture width 50mm and 200mm optional; 4 effective creep space

- Q: What is the purpose of using the three - way geogrid in the gravel layer

- Or the design requirements are back folding 30CM

- Q: Can geogrids be used in retaining wall reinforcement systems?

- Yes, geogrids can be used in retaining wall reinforcement systems. Geogrids are commonly used to enhance the stability and strength of retaining walls by improving soil retention and reducing lateral pressure. They provide additional support to the wall structure and prevent soil erosion, helping to increase the overall durability and longevity of the retaining wall.

Send your message to us

Titan Geogrids PP Biaxial Geogrid for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords