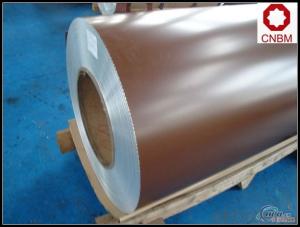

Powder Coated Aluminum Remelting Coil Like Aluminium Ingot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

ALUMINIUM FOIL

ALLOY:AA1***

TEMPER: F O H14 H16 H18 H22 H24 H26

THICKNESS: 0.006MM-0.20MM

WIDTH: 200MM-1600MM

COATING: HSL/PRIMER

STANDAR: GB/T 3198-2003

2.Application

Our Remelting aluminium coil is the same as aluminium ingot, and the price is cheaper.

3.Why you can truct us?

We promise the best quality and price!

4.Pictures

5.FAQ

1)what is aluminum?

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

2)What's kind of payment term we can supply?

CIF,CFR, FOB and other.

3)Can we supply samples?

Yes, we can!

4)What can you do if you have other quastions?

You can contact us freely at any time!

- Q: Can aluminum coils be used in the production of heat shields?

- Heat shields can indeed be made using aluminum coils. Aluminum is a preferred option for heat shields because of its exceptional thermal conductivity, lightweight characteristics, and ability to reflect radiant heat effectively. Typically, heat shields are designed to safeguard delicate components or structures from excessive heat generated by engines, exhaust systems, or other sources. By shaping and sizing aluminum coils, one can create efficient heat shields that disperse heat and prevent its transfer to surrounding areas. Furthermore, aluminum exhibits corrosion resistance, making it suitable for applications where heat shields may encounter harsh environments or chemicals. All in all, aluminum coils are an appropriate material choice for producing heat shields due to their thermal properties, adaptability, and long-lasting nature.

- Q: why is aluminum oxide used more frequently than silicon carbide as an abrasive?What r the different types of tool feed mechanism in USM process.

- Aluminum oxide and silicon carbide are used to grind two completely different sets of materials. Steels and other ferrous alloys are best ground with an aluminum oxide wheel, and the majority of grinding tasks are grinding ferrous alloys. At home, tools are made of steel, and so home bench grinders come with Al2O3 wheels. The same with handheld angle grinders - most welding is done with ferrous alloys. For aluminum and carbides, a silicon carbide wheel will yield better results.

- Q: How are aluminum coils inspected for quality?

- Aluminum coils are inspected for quality through a series of rigorous tests and inspections. These inspections are crucial to ensure that the coils meet the required industry standards and specifications. One common method used to inspect aluminum coils is visual inspection. Trained inspectors visually examine the coils for any visible defects such as surface scratches, dents, or any other physical imperfections that may affect the quality of the coil. This inspection is typically done using specialized lighting and magnification equipment to ensure thorough examination. Another important inspection method is dimensional inspection. In this process, the dimensions of the aluminum coils are measured and compared against the specified tolerances. This helps ensure that the coils meet the required size and shape requirements. Coating inspection is also an essential part of the quality inspection process. The coating on aluminum coils is inspected for uniformity, adhesion, and thickness. Specialized instruments are used to measure the coating thickness and ensure that it meets the specified requirements. Additionally, mechanical properties such as tensile strength, yield strength, and elongation are tested to assess the strength and durability of the aluminum coils. These tests involve subjecting samples from the coils to controlled stress and measuring their response. Lastly, various non-destructive testing techniques are employed to detect any hidden defects or flaws that may not be visible to the naked eye. These techniques include ultrasonic testing, eddy current testing, and dye penetrant testing. These methods help identify any internal defects such as cracks or voids that could compromise the quality of the aluminum coils. Overall, a combination of visual inspections, dimensional measurements, coating inspections, mechanical property testing, and non-destructive testing techniques are employed to thoroughly inspect aluminum coils and ensure their quality before they are deemed suitable for use in various industries such as construction, automotive, and aerospace.

- Q: Is it possible to utilize aluminum coils in the process of water treatment?

- <p>Yes, aluminum coils can be used for water treatment. They are often used in processes such as coagulation and flocculation, where aluminum salts are added to the water to help remove suspended particles and impurities. The aluminum ions react with the particles in the water to form larger, heavier particles that can be more easily settled or filtered out. Additionally, aluminum coils can be part of an electrode system in electrocoagulation processes, where an electric current is used to treat water by generating aluminum ions at the anode. This method is effective for removing various contaminants, including heavy metals, bacteria, and organic compounds.</p>

- Q: Can aluminum coils be used for automotive body panels?

- Certainly, automotive body panels can be made using aluminum coils. In fact, aluminum is gaining popularity in the automotive sector due to its numerous advantages. Its lightweight nature contributes to enhanced fuel efficiency and overall vehicle performance. Furthermore, aluminum exhibits exceptional resistance to corrosion, making it a durable option for automotive body panels. Additionally, aluminum can be easily shaped and molded, enabling intricate designs and improved aerodynamics. All in all, utilizing aluminum coils for automotive body panels presents a viable choice with a multitude of benefits.

- Q: Can aluminum coils be used for heat exchangers?

- Yes, aluminum coils can be used for heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. These coils are typically used in applications where heat transfer is required, such as in HVAC systems, refrigeration units, and automotive radiators. The high thermal conductivity of aluminum allows for efficient heat transfer, while its corrosion resistance ensures durability and a longer lifespan for the heat exchanger. Additionally, aluminum coils can be easily formed into various shapes and sizes, making them versatile for different heat exchanger designs.

- Q: How much is one square aluminum gate and five hard door?

- On the Alibaba website search "roll gate", there are many manufacturers, you can ask them.

- Q: What are the common cleaning and maintenance products for aluminum coils?

- Aluminum coils can be cleaned and maintained using various products. One popular option is a mild detergent mixed with water. This mixture can be applied to the coils using a soft brush or cloth, and then rinsed off with water. Another commonly used product is a coil cleaner specifically designed for aluminum surfaces. These cleaners are usually available in spray or foam form and effectively remove dirt, grease, and oxidation from the coils. It is important to carefully follow the manufacturer's instructions when using these cleaners. Additionally, a mixture of white vinegar and water can be used to clean aluminum coils. This natural cleaning solution effectively removes mineral deposits and stains. It can be applied with a cloth or sponge and then rinsed off with water. Regular maintenance of aluminum coils also includes using a coil coating or sealant. These products create a protective layer on the coils, preventing corrosion and extending their lifespan. It is advisable to apply the coating or sealant according to the manufacturer's instructions. When cleaning and maintaining aluminum coils, it is crucial to avoid using abrasive cleaners, bleach, or harsh chemicals as they can damage the coils. If uncertain about the appropriate cleaning and maintenance products for specific aluminum coils, it is recommended to consult the manufacturer's guidelines or seek professional advice.

- Q: Is it possible to utilize a magnetic stirrer to determine the magnetic characteristics of an aluminum coil?

- <p>No, you cannot use a magnetic stirrer to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not respond to magnetic fields in the way magnetic materials like iron, nickel, or cobalt do. A magnetic stirrer operates by creating a rotating magnetic field to stir substances, but since aluminum is non-magnetic, it will not be affected by the stirrer's field. To test magnetic properties, you would need to use materials that are ferromagnetic or paramagnetic, or employ other methods such as a magnetometer for measuring magnetic fields.</p>

- Q: Can aluminum coils be used in vacuum applications?

- Yes, aluminum coils can be used in vacuum applications. Aluminum is a commonly used material in vacuum systems due to its excellent properties such as low outgassing, high thermal conductivity, and good corrosion resistance. These properties make aluminum coils suitable for various vacuum applications, including but not limited to, vacuum chambers, vacuum pumps, cryogenic systems, and particle accelerators. However, it is important to note that aluminum can be reactive with certain gases or chemicals, so it is essential to consider the specific requirements and compatibility of the vacuum application before using aluminum coils.

Send your message to us

Powder Coated Aluminum Remelting Coil Like Aluminium Ingot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords