Jual Geotextile Polypropylene Smooth Geomembrane with High Stabilization and Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Flexible membranes are used in a variety of applications, such as:

Landfill lining

to protect the ground water from contamination.

Landfills capping

to prevent fluid flow in the landfill, to trap and properly vent the gases generated during decomposition of organic waste and to permit efficient revegetation and restoration of the area.

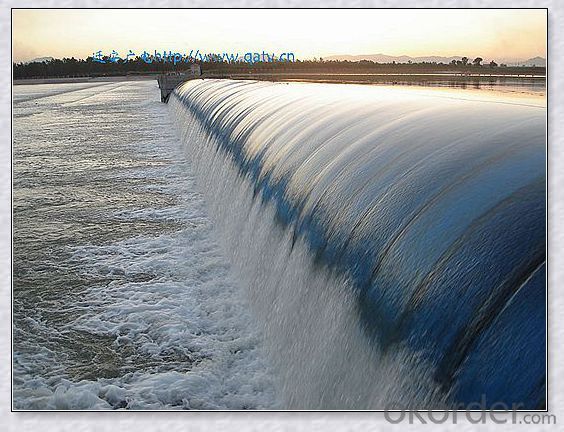

Water reservoirs

for collecting rain-water before it reaches the sea.

Reservoirs for waste-water

to protect the groundwater sources or streams.

Pond-lining

for artificial lakes and irrigation of farms.

Irrigation canals

an economic alternative to concrete and compacted earth for transporting water and irrigating large areas. Also used to reduce seepage from existing deteriorated concrete linings.

Protection of lake banks

for soil stabilization.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the factors affecting the selection of geotextiles?

- The factors affecting the selection of geotextiles include the type and severity of the application, desired performance characteristics such as strength and filtration properties, site conditions such as soil type and slope stability, environmental considerations such as chemical resistance and durability, and cost-effectiveness.

- Q: How are geotextiles made?

- Geotextiles are made by weaving or knitting synthetic fibers together to form a permeable fabric with specific properties suitable for various civil engineering applications.

- Q: How much is the geotextile machine?

- Cheaper point of the 4500 better 8,000 more

- Q: How do geotextiles help in reducing soil erosion caused by wind?

- Geotextiles help in reducing soil erosion caused by wind by creating a barrier that prevents the soil from being lifted and carried away by strong winds. It acts as a protective layer by stabilizing the soil, preventing its displacement and preserving its integrity.

- Q: How do geotextiles contribute to erosion control on slopes?

- Geotextiles contribute to erosion control on slopes by acting as a barrier that prevents soil erosion. They are typically placed on the surface of slopes to stabilize the soil and prevent the movement of sediment. The geotextiles help to reduce the velocity of water runoff, allowing it to infiltrate into the soil rather than carrying away the soil particles. Additionally, geotextiles can promote vegetation growth by providing a stable surface for plant roots to anchor, further minimizing erosion on slopes.

- Q: What is the latest offer for geotextile prices?

- Geotextile Product Description: Geotextile is made of polypropylene, acrylic yarn as raw material woven by the geosynthetics, widely used in water conservancy, electricity, harbors, highways, railway construction and other geotechnical engineering. Geotextiles Category: Geotextiles a wide range of ordinary geotextile refers to the permeable geotextile, also known as short wire geotextile, polyester geotextile other filament geotextile, waterproof geotextile and so on. Geotextile Price Description: There are many manufacturers of geotextiles across the country, the product offers different prices affected by the impact of raw materials and regional differences, a good product should be a penny goods. The price according to product specifications offer direct contact consultation 182 power 6686 words 2233 to find professional manufacturers to understand, product prices dynamic. Hope to help you

- Q: Can geotextiles be used in retaining wall reinforcement?

- Yes, geotextiles can be used in retaining wall reinforcement. Geotextiles are often used as a separation and filtration layer in retaining walls to prevent soil erosion and improve their stability. They can help distribute loads, reduce soil movement, and enhance the overall performance and durability of the retaining wall system.

- Q: What are the different geotextile installation techniques for erosion control blankets?

- There are several geotextile installation techniques for erosion control blankets, including anchoring, trenching, and stapling. Anchoring involves securing the blanket with stakes or pins to prevent movement. Trenching involves digging a trench along the edges of the blanket and burying it to provide additional stability. Stapling involves using landscape staples or metal pins to fasten the blanket to the ground. Each technique is used based on the specific site conditions and requirements.

- Q: Can geotextiles be used in oil and gas industry applications?

- Yes, geotextiles can be used in oil and gas industry applications. Geotextiles are commonly used for erosion control, soil stabilization, and filtration purposes in various industries, including the oil and gas industry. They can be used in applications such as pipeline construction, drilling operations, and containment systems. Geotextiles help to prevent soil erosion, provide stability for construction sites, and aid in filtration and separation of materials in oil and gas operations.

- Q: Garage roof covered with non-woven or geotextile cloth

- Geotextile also known as non-woven fabrics, with 200 to 300 grams of short wire geotextile can be

Send your message to us

Jual Geotextile Polypropylene Smooth Geomembrane with High Stabilization and Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords