Polymer Geogrids - Warp Knitted Polyester Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

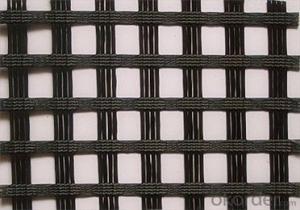

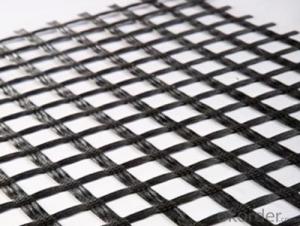

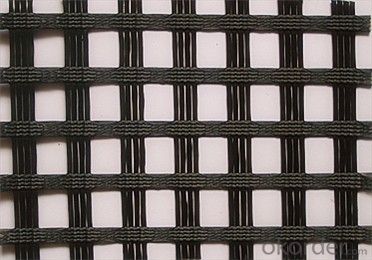

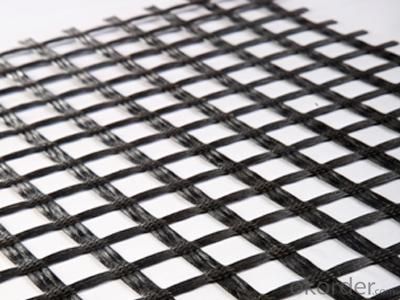

Structure of Warp Knitted Polyester Geogrid Description:

Polyester geogrd applies chemical fiber with extreme strong elasticity modulus,make it into grid loom stare through oriented warp knitting ,then ater coating the geogrid is formed with the name of "fiber soft steel".

Main Features of Warp Knitted Polyester Geogrid:

Polyester geogrid has high tensile strength and high tear-resisitant

Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle.

Polyester geogrid is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed

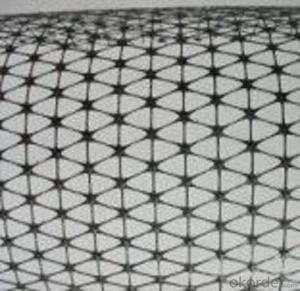

Warp Knitted Polyester Geogrid Images

Warp Knitted Polyester Geogrid Specification:

Item | Art.No. | PLB010101 | PLB010102 | PLB010103 | PLB010104 | PLB010105 |

Specs | TGDG25 | TGDG35 | TGDG50 | TGDG80 | TGDG110 | |

Unit weight,g/m2 | 370±50 | 450±50 | 550±50 | 700±50 | 1100±50 | |

Width,m | 1.0+0.2/-0 or 2.0+0.2/-0 | |||||

Tensile strength, kN/m≥ | 25 | 35 | 50 | 80 | 110 | |

Elongation,%≤ | 10 | |||||

Tensile strength at 2% strain,kN/m≥ | 7 | 10 | 12 | 26 | 32 | |

Tensile strength at 5% strain,kN/m≥ | 14 | 20 | 28 | 48 | 64 | |

Roll length,m | 50+0.25/-0 | |||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What is the meaning of two-way 50kN geogrid

- The code is GSL, GSL50 represents the longitudinal and transverse tensile strength more than 50KN of plastic geogrids.

- Q: What are the advantages of using geogrids?

- Geogrids offer several advantages in civil engineering and construction projects. Firstly, they enhance soil stability and reinforce weak soils, preventing soil erosion and improving load-bearing capacity. Secondly, geogrids can reduce construction costs by allowing for the use of locally available and lower-quality materials instead of expensive fill materials. Additionally, they provide long-term durability, resistance to chemical degradation, and high tensile strength, ensuring the longevity and structural integrity of the project. Moreover, geogrids are easy to install, lightweight, and flexible, making them convenient for various applications and reducing labor requirements. Overall, using geogrids results in improved soil performance, cost-effectiveness, and efficient construction processes.

- Q: What is the effect of geogrid aperture size on performance?

- The effect of geogrid aperture size on performance is that it directly influences the soil's interlocking capability with the geogrid. Smaller aperture sizes enhance the interlocking mechanism, leading to improved load distribution and higher tensile strength. On the other hand, larger aperture sizes may reduce the interlocking efficiency, potentially compromising the geogrid's overall performance in terms of reinforcement and stabilization.

- Q: How much is the tensile strength of geogrid???????

- Divided into three categories: the overall plastic stretch: two-way products: 15KN--50KN one-way products: 50KN---300KN

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge piers?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth bridge piers. Geogrids are commonly used in such applications to provide additional strength, stability, and load-bearing capacity to the soil, enhancing the performance and longevity of the bridge piers.

- Q: How do geogrids enhance the performance of geotextile tubes?

- Geogrids enhance the performance of geotextile tubes by providing additional strength and stability. They act as a reinforcement layer within the tube, preventing deformation and maintaining the desired shape. Geogrids also help distribute the load evenly, increasing the overall stability and durability of the geotextile tube system.

- Q: What are the factors that affect the installation quality of geogrids?

- The factors that affect the installation quality of geogrids include the type and quality of the geogrid material, proper surface preparation, adequate compaction, appropriate tensioning and anchoring, proper overlap and seam construction, and adherence to manufacturer's guidelines and specifications. Additionally, factors such as weather conditions, soil type, and site-specific requirements can also impact the overall installation quality of geogrids.

- Q: Can geogrids be installed on steep slopes?

- Yes, geogrids can be installed on steep slopes. Geogrids are commonly used in slope stabilization and reinforcement projects, including on steep slopes. They help enhance soil stability and prevent erosion, making them suitable for installation on steeper slopes where erosion and soil instability may be more prominent.

- Q: Do geogrids provide reinforcement to geosynthetic clay liners in waste containment facilities?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in waste containment facilities. Geogrids are typically used to enhance the stability and strength of geosynthetic clay liners, improving their ability to withstand lateral forces and prevent soil erosion.

- Q: Where can I do three to the geogrid test?

- Currently did not find the corresponding three geogrid test specification, how to determine the direction of the three cells, how to load are not standardized

Send your message to us

Polymer Geogrids - Warp Knitted Polyester Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords