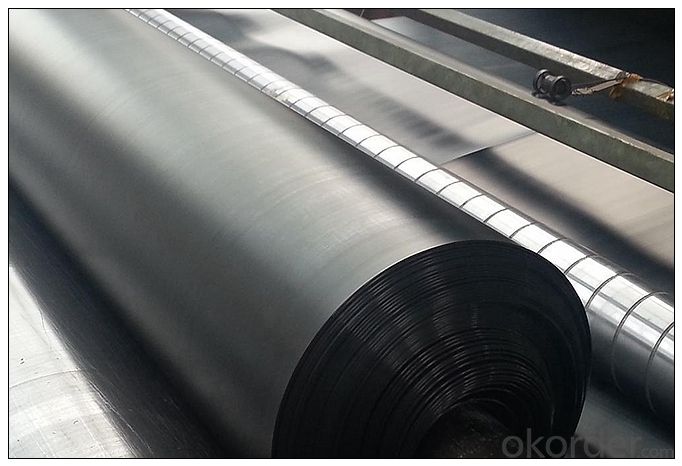

Geomembrana Engepol Polyethylene HDPE Geomembrane for Agricultural Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Function:

Waterproof

Application:

Water conservancy projects

Landfill treatment projects

Mineral waterproofing

Agricultural waterproofing

HDPE Geomembrane

Thickness: 1.0mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

LDPE Geomembrane

Thickness: 0.1mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

LLDPE Geomembrane

Thickness: 0.5mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

Applicable to river dams, tunnels, drainage bank seepage, metallurgy and chemical industry pollution prevention, construction, transportation, environmental protection works.

PE film thickness: 0.2mm-0.8mm Product Specifications: Width 4m-6m, weight 300g/m2-2400g/m2.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How to make sure there is no bubble on the film?

- 1. Cutting: The specifications of glass film are cut into veneers than are to be larger than about 1cm. This will avoid the trouble of sticking to the side (while more than one side) and repeating again. 2. To clean the glass: Before pasting the glass paper, the grease, stains and dust on the glass should be cleaned with enough water( the best is t o add some liquid detergent). The purpose of spraying water is to temporarily reduce the viscosity of the glass film, and the viscosity of the glass film will not be affected after it is dry. 3. To remove the back release liner: To remove the membrane type glass film back (with rubber surface) also enough spray in the water, it will paste process can random in the glass move back and forth which is convenient to the proper position. 4. Pasting: First, to paste the glass film on the glass after the average proportion, and post it on the glass top and aligned paste from the top to the down. If it is not alined in one-time, it can be repeatedly reopened to paste (the benefits of spraying water) 5. To exhaust bubbles: To use the scraper or IP card from the center to the around water and scraping bubble, catch out water and air bubbles with a needle or blade punctured to smooth. Until there is no any water and air bubbles, and the glass film is completely sticked on the glass so far. 6. To cut off the rest part: After pasting the film, to cut off the excess part with the blade.

- Q: Are geomembranes resistant to hydraulic pressure?

- Yes, geomembranes are designed to be resistant to hydraulic pressure. They are commonly used in various applications such as landfill liners, water containment structures, and tunnels, where they are able to withstand the pressure exerted by liquids or gases.

- Q: Is it worthwhile to stick membrane for high-end mobile phone?

- It is worthwhile for common cellphone but not for high-end mobile phone. The film for high-end mobile phone will be better than that of common mobile phone. But when sticking film, you need to see the cellphone material. Some mobile phone does not need to stick film, not to say that the high-end mobile phone film.

- Q: What is the difference between the matte stick membrane and HD stick membrane?

- The difference is as follows: HD stick membrane transmittance is high, after pasting it will not affect the screen display, but most are not anti fingerprint, matte film is anti fingerprint, but, after posting up, poeple will have a vague feeling when looking at the screen, now the HD anti fingerprint membrane and matte HD matte membrane is anti fingerprint and high definition.

- Q: What is the one-way membrane?

- The architectural glass film. It can only see the outside from the inside, but the outside can not see the inside.

- Q: What is the construction technology of the color permeable concrete project?

- The construction technology of the color permeable concrete project. 1. To take use of the cementitious material, construction method and consolidation after the wood color asphalt concrete pavement is refers to the decoloring asphalt and various color stone, pigments and additives, and other materials under the specific temperature mixing; 2. Color concrete adding pigment should generally be issued by the laboratory of mixture ratio of construction. The pigment is usually added according to the amount of the cement, and it generally can not be more than 20% of the amount of cement.

- Q: Which is better, domestic or imported geomembrane?

- Although China is now also developing geomembrane, but also it is just at the beginning. Foreign environmental protection course is earlier and more developed than China's. So we have to admit that foreign HDPE geomembrane is more quality than domestic geomembrane. Although domestic geomembrane is cheaper, most of the domestic geomembrane use reused materials, so service life is greatly reduced, which is known to all. While imported HDPE geomembrane, such as geomembrane produced in Canadian Solmax International Inc. do not use reused materials, so the quality is absolutely guaranteed. Moreover, Solmax International Inc. is the world's largest and most professional supplier of HDPE geomembrane. So I think imported geomembrane has higher cost performance ratio!

- Q: What are the long-term performance expectations for geomembranes?

- The long-term performance expectations for geomembranes include durability and resistance to environmental factors such as UV radiation, temperature variations, and chemical exposure. They are expected to maintain their structural integrity and impermeability for decades, effectively preventing leaks and contamination. However, proper installation, maintenance, and regular inspections are crucial to ensure their longevity and performance over time.

- Q: what is the role of home color film?

- 1, color film is a new concept of home decoration materials, it is a simple and convenient form of film, on the tiles, furniture, glass, all kinds of table and household appliances foil. Home color film is easy to use, do not shovel the wall, not ground-breaking, directly attached immediately with cement walls can be affixed. it does not burn or bubble when encountering fire or water. 2, color equipment film drawback is not very abrasive resistant, it easily loses the adheive property in wet weight of the house. Some color film home afraid of the sun compared to the liquid wallpaper, a little expensive. Liquid wallpaper can freely design their own style, different style decoration. With respect to the home color film is more durable and can maintain long-term as new, no seams, not from the skin, not falling, dust-proof, waterproof, moisture-proof, flame retardant, anti scrub, anti-moth, long life and other characteristics (general service life not less than 20 years).

- Q: Should the plastic film of mattress be removed?

- You can take followings as a reference. It should be removed or it will impede the air circulation of the mattress which can lead to mildew, bacteria and acarid. This problem can be settled when the film is removed. Then don't block the venthole of mattress. The mattress can not be cleaned by water. So it is better to use quilt cover that can be washed frequently to keep the mattress clean. The regular retroflexion of the mattress can increase its service life.

Send your message to us

Geomembrana Engepol Polyethylene HDPE Geomembrane for Agricultural Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords